A kind of method for preparing agarose

A technology of agarose and colloid, applied in the field of preparation of agarose, can solve the problems of long production cycle, high cost, cumbersome production process, etc., achieve the effect of improving sample quality, improving gel strength, and reducing intermediate production links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

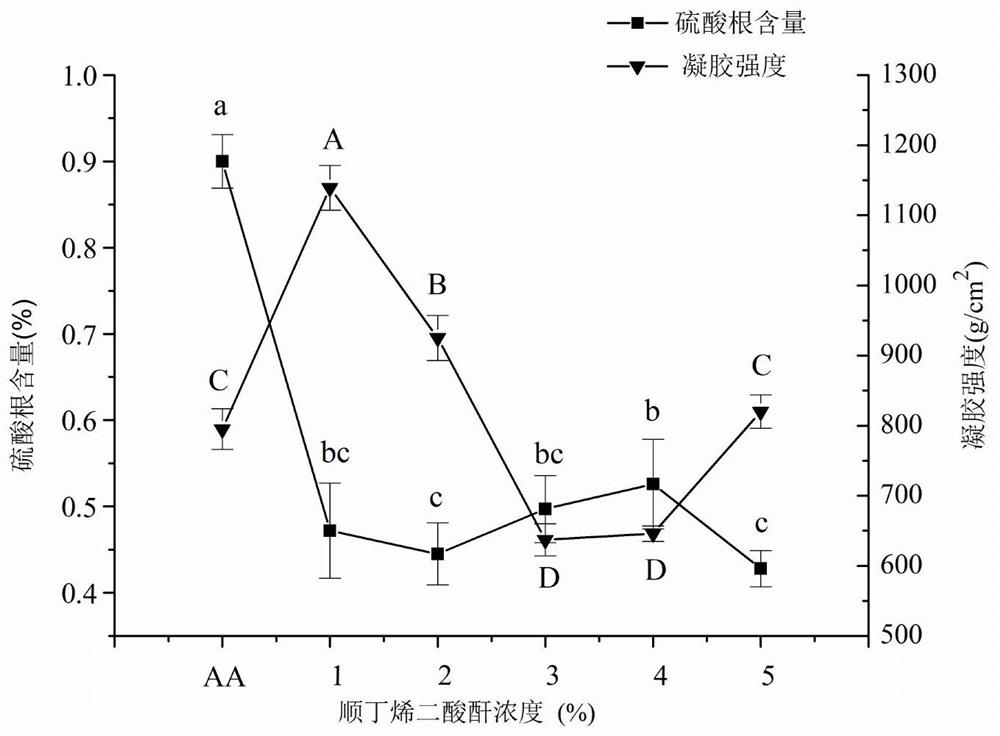

[0045] Embodiment 1 Different maleic anhydride addition amounts

[0046] Alkali treatment: Rinse the gracilis with tap water, dry it naturally, take 100g of the dried grass, add 7% (w / v) NaOH solution at a ratio of 1g:20mL (m:v) algae water Constant temperature treatment at 90°C for 3h. After the alkali treatment is completed, use tap water for soaking and rinsing, with an interval of 40 minutes each time, until the pH of the lotion is neutral.

[0047] Acidification treatment: After the step of alkali treatment, the Grapefruit was added with sulfuric acid, oxalic acid and EDTA in the proportions of 0.064% (v / v), 0.052% (m / v) and 0.012% (m / v) of the total system Disodium, treated for 40min, poured off the liquid, soaked and rinsed until the pH of the lotion was neutral.

[0048] Bleaching treatment: add water to the acidified grass, then add 0.1% (w / v) sodium hypochlorite solution, bleach for 40 min, and then soak and rinse until the pH of the lotion is neutral.

[0049] Bo...

Embodiment 2

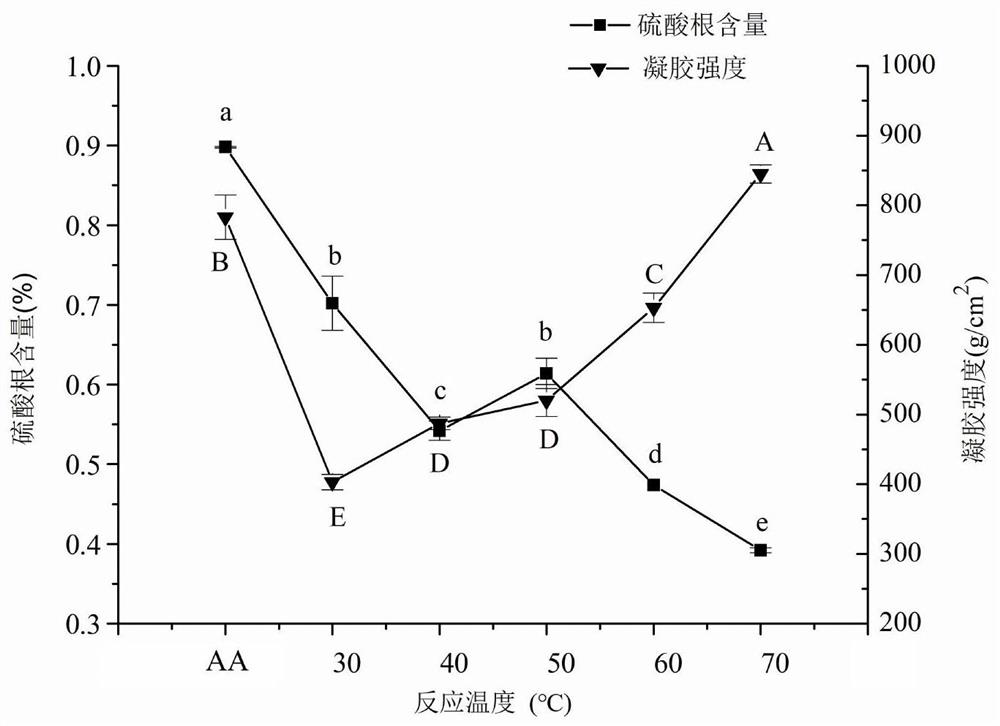

[0054] Example 2 at different temperatures

[0055] Alkali treatment: Rinse the gracilis with tap water, dry it naturally, take 100g of the dried grass, add 7% (w / v) NaOH solution at a ratio of 1g:20mL (m:v) algae water Constant temperature treatment at 90°C for 3h. After the alkali treatment is completed, use tap water for soaking and rinsing, with an interval of 40 minutes each time, until the pH of the lotion is neutral.

[0056] Acidification treatment: After the step of alkali treatment, the Grapefruit was added with sulfuric acid, oxalic acid and EDTA in the proportions of 0.064% (v / v), 0.052% (m / v) and 0.012% (m / v) of the total system Disodium, treated for 40min, poured off the liquid, soaked and rinsed until the pH of the lotion was neutral.

[0057] Bleaching treatment: add water to the acidified grass, then add 0.1% (w / v) sodium hypochlorite solution, bleach for 40 min, and then soak and rinse until the pH of the lotion is neutral.

[0058] Boiled gelatin: After w...

Embodiment 3

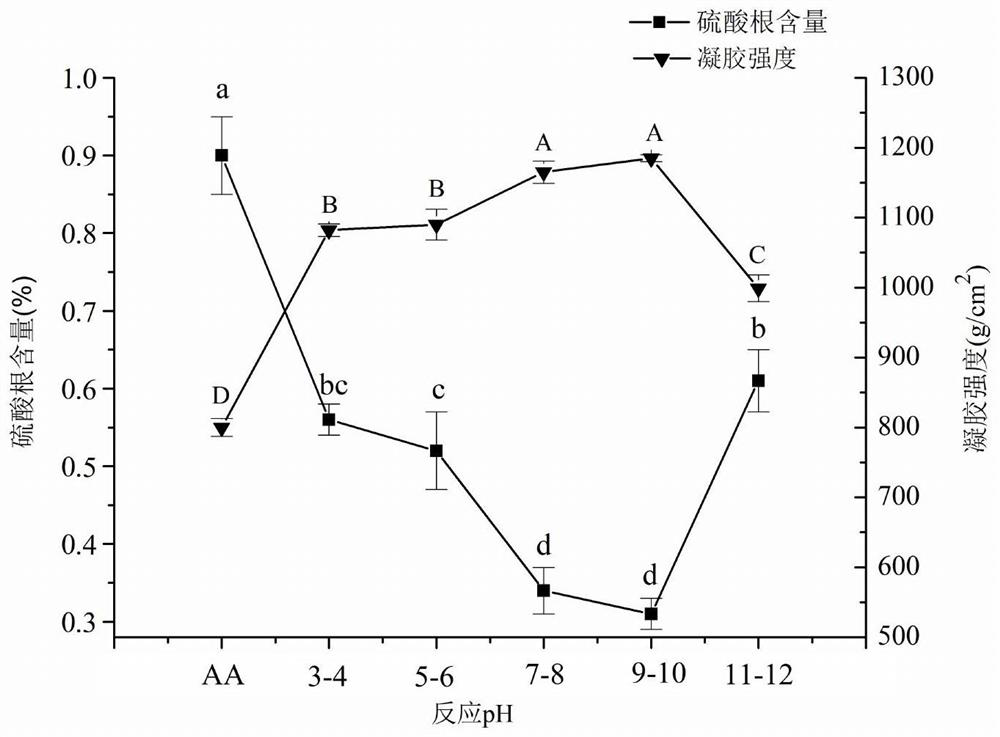

[0063] Example 3 Different pH

[0064] Alkali treatment: Rinse the gracilis with tap water, dry it naturally, take 100g of the dried grass, add 7% (w / v) NaOH solution at a ratio of 1g:20mL (m:v) algae water Constant temperature treatment at 90°C for 3h. After the alkali treatment is completed, use tap water for soaking and rinsing, with an interval of 40 minutes each time, until the pH of the lotion is neutral.

[0065] Acidification treatment: After the step of alkali treatment, the Grapefruit was added with sulfuric acid, oxalic acid and EDTA in the proportions of 0.064% (v / v), 0.052% (m / v) and 0.012% (m / v) of the total system Disodium, treated for 40min, poured off the liquid, soaked and rinsed until the pH of the lotion was neutral.

[0066] Bleaching treatment: add water to the acidified grass, then add 0.1% (w / v) sodium hypochlorite solution, bleach for 40 min, and then soak and rinse until the pH of the lotion is neutral.

[0067] Boiled gelatin: After washing, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com