Easy-to-clean polypropylene material and preparation method thereof

A polypropylene material and polypropylene technology, applied in the field of polypropylene material and its preparation, can solve the problems of troublesome cleaning, stains or dirt, inconvenience to users, etc., and achieve the effect of avoiding stains or dirt contamination and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

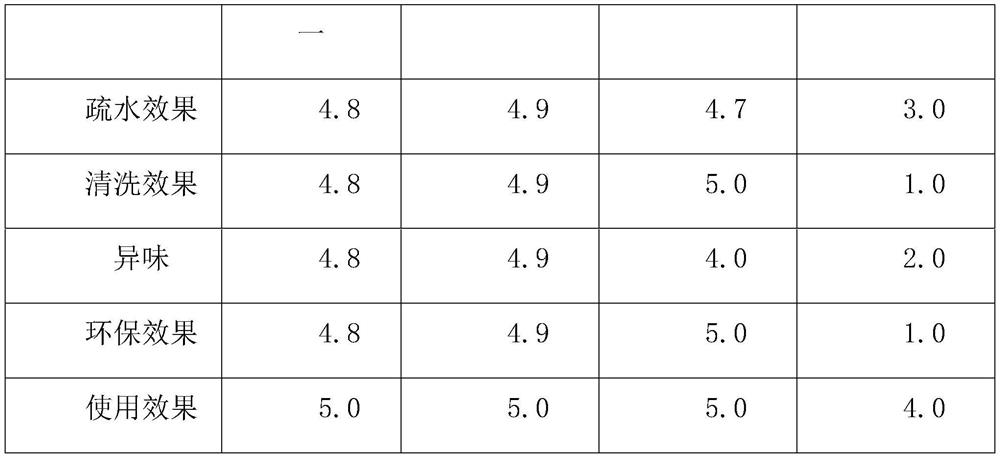

[0019] An easy-to-clean polypropylene material, the parts by weight of each component of the material are 10-15 parts of polypropylene A, 50 parts of polypropylene B, 5 parts of polypropylene C, 1 part of flame retardant, 1 part of hydrophilic agent, and talcum powder 1 part, 0.01 part of antioxidant, 1 part of titanium dioxide, 0.1 part of black powder, 0.1 part of titanium yellow and 0.1 part of iron brown; the model of described polypropylene A is PP150 powder; the model of described polypropylene B It is PPH1500; the model of the polypropylene C is PP8025; the model of the flame retardant is HSF918; the model of the hydrophilic agent is RL105; the model of the antioxidant is 1010; Model is R69; The model of described black powder is 660R; The model of described titanium yellow is K2001; The model of described tephragm is 130. The parts by weight of each component of the flame retardant are 1 part of urea, 2 parts of diammonium hydrogen phosphate and 1 part of borax. The a...

Embodiment 2

[0021] An easy-to-clean polypropylene material, the parts by weight of each component of the material are 13.98 parts of polypropylene A, 66 parts of polypropylene B, 8.5 parts of polypropylene C, 1.5 parts of flame retardant, and hydrophilizing agent 2 parts, 3 parts of talcum powder, 0.02 part of antioxidant, 3.2 parts of titanium dioxide, 0.5 part of black powder, 0.7 part of titanium yellow and 0.6 part of iron brown; the model of described polypropylene A is PP150 powder; The model of polypropylene B is PPH1500; the model of polypropylene C is PP8025; the model of flame retardant is HSF918; the model of described hydrophilic agent is RL105; the model of described antioxidant is 1010; The model of the described titanium dioxide is R69; the model of the described black powder is 660R; the model of the described titanium yellow is K2001; the parts by weight of each component of the flame retardant are 1 part of urea, 2 parts of diammonium hydrogen phosphate 1 part and 1 part...

Embodiment 3

[0023] An easy-to-clean polypropylene material, the parts by weight of each component of the material are 15 parts of polypropylene A, 70 parts of polypropylene B, 10 parts of polypropylene C, 3 parts of flame retardant, 3 parts of hydrophilic agent, and 5 parts of talcum powder , 0.03 parts of antioxidant, 5 parts of titanium dioxide, 1 part of black powder, 1 part of titanium yellow and 2 parts of iron brown; the model of the described polypropylene A is PP150 powder; the model of the described polypropylene B is PPH1500 The model of the polypropylene C is PP8025; the model of the flame retardant is HSF918; the model of the hydrophilic agent is RL105; the model of the antioxidant is 1010; the model of the titanium dioxide is R69; the model of described black powder is 660R; the model of described titanium yellow is K2001; The parts by weight of each component of the flame retardant are 5 parts of urea, 3 parts of diammonium hydrogen phosphate and 5 parts of borax. The antio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com