Hydrophobic recycled aggregate ecological drainage brick and preparation method thereof

A recycled aggregate and water-repellent technology, which is applied in the field of construction waste resource treatment, can solve problems such as poor drainage effect, difficult water drainage, water accumulation in drainage bricks, etc., to improve drainage speed, water repellency, and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0049] The preparation method of hydrophobic nano silicon dioxide:

[0050] Add 1kg of nano-silica, 0.09kg of γ-aminopropyltriethoxysilane and 6kg of ethanol into the reaction kettle, mix and stir at 60°C for 2h, filter to obtain a solid after stirring, and dry the obtained solid in an oven at 50°C for 1h , to obtain hydrophobic nano-silica.

Embodiment 1

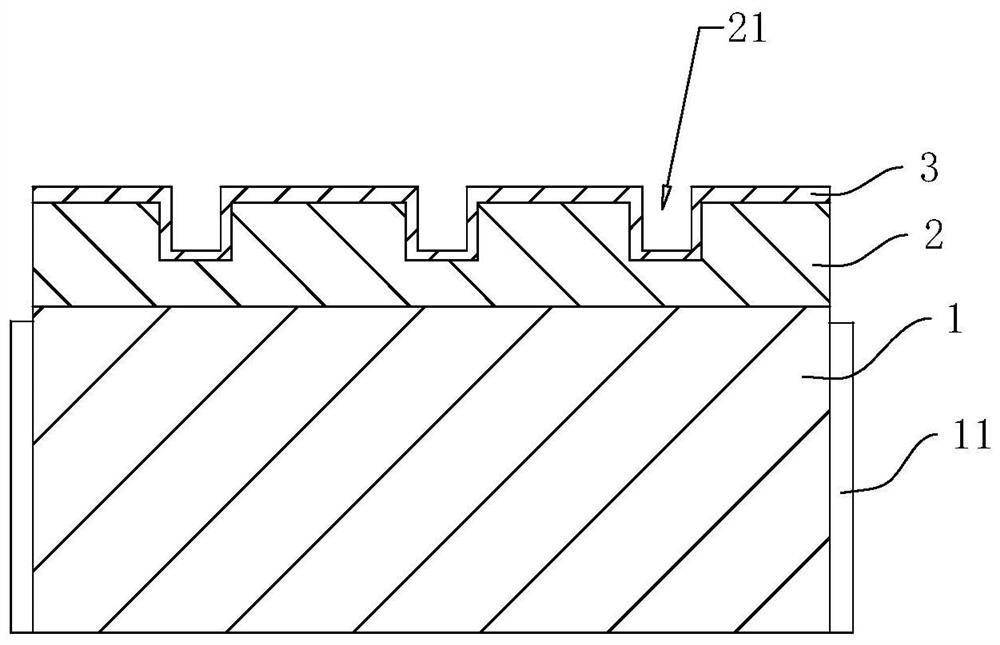

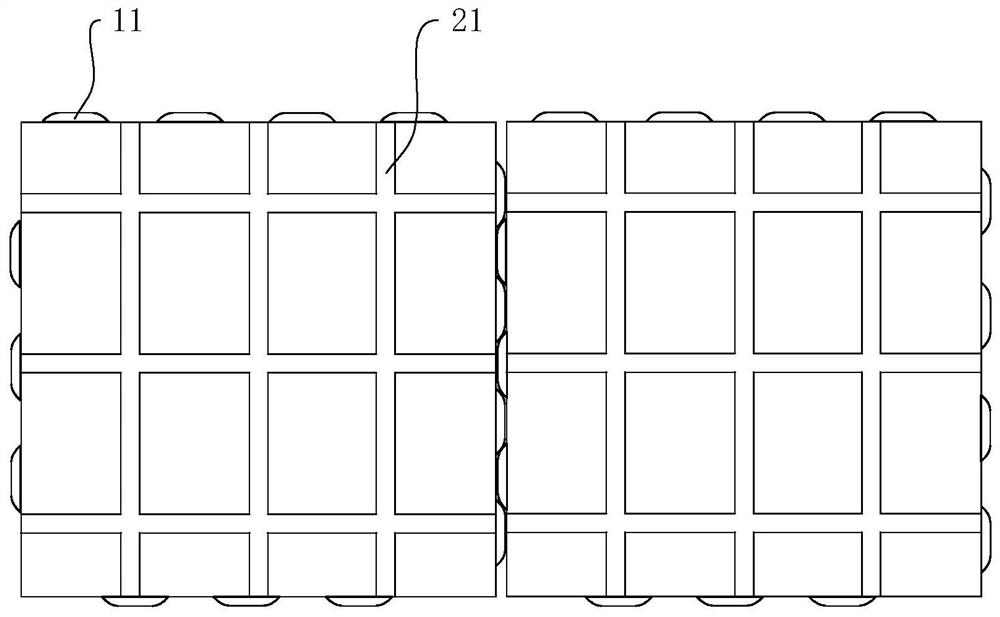

[0053] Preparation method of hydrophobic recycled aggregate ecological drainage brick:

[0054]S1. Add 36kg of fine sand with a particle size of 1~5mm, 74kg of recycled coarse aggregate with a particle size of 5~10mm, and 0.1kg of polycarboxylate superplasticizer into the first mixer, stir for 1min, then add 44kg of cement, continue stirring for 1min, and then add 15kg of water, continue stirring for 2 minutes to obtain the bottom slurry; add 8kg of cement, 6.2kg of fine sand and 3.5kg of water into the second mixer, and stir for 2 minutes to obtain the top slurry; first add the bottom slurry to the brick machine, vibrate, and Under the action of the brick machine mold, the base material layer is formed, and then the fabric slurry is added to the brick machine, and the vibration is continued to form a plane surface fabric layer, and a green body is formed, and finally the green body is transferred to the curing room for curing.

[0055] S2. Add 0.16kg epoxy resin, 0.02kg T-31 ...

Embodiment 2~ Embodiment 3

[0058] The difference between Embodiment 1, Embodiment 2 and Embodiment 3 lies in the step S2, as shown in Table 1 for details.

[0059] Table 1

[0060] Example 1 Example 2 Example 3 Silicon carbide (kg) 0.16 0.42 0.3 Hydrophobic nano silica (kg) 0.08 0.28 0.21 Phenolic resin (kg) 0.3 1 0.5 Polyamide wax paste (kg) 0.22 0.3 0.15 ethanol (kg) 5 7 6.3

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com