Water-based high-adhesion water-resistant paint and preparation method thereof

A water-resistant paint, water-based technology, applied in coatings, alginic acid coatings, epoxy resin coatings, etc., can solve the problems of paint film stability and aesthetic discount, environmental pollution, paint film peeling, etc., to achieve good water solubility and Stability, avoid oxidation or reduction, improve adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention provides a kind of preparation method of water-based high adhesion water-resistant paint comprising the following steps:

[0030] (1) Mix and react halogen salt, copper ion salt and sulfite according to the molar ratio of 2.8:1.5:1 for 1 hour, then add barium halide to the mixed solution and filter to remove the precipitate to obtain cuprous halide complex ion [CuX 2 ] - solution, to [CuX 2 ] - Add stabilizer to the solution for later use;

[0031] (2) the mass components are 20 parts of polyurethane resin, 30 parts of water-based acrylic resin, 15 parts of epoxy resin, 0.8 part of hydroxymethyl cellulose, 25 parts of monovalent alginate, 22 parts of water and stabilized [CuX 2 ] - The solutions are mixed and stirred evenly to obtain the water-based high adhesion water-resistant paint.

[0032] Wherein the halide salt, barium halide, cuprous halide complex ion [CuX 2 ] - The halogen element X in is a chlorine element; the valence of the cation in t...

Embodiment 2

[0035] The invention provides a kind of preparation method of water-based high adhesion water-resistant paint comprising the following steps:

[0036](1) Mix and react halogen salt, copper ion salt and sulfite according to the molar ratio of 3.5:2:1 for 2 hours, then add barium halide to the mixed solution and filter to remove the precipitate to obtain cuprous halide complex ion [CuX 2 ] - solution, to [CuX 2 ] - Add stabilizer to the solution for later use;

[0037] (2) the mass components are 32 parts of polyurethane resin, 38 parts of water-based acrylic resin, 22 parts of epoxy resin, 4 parts of hydroxymethyl cellulose, 33 parts of monovalent alginate, 26 parts of water and stabilized [CuX 2 ] - The solutions are mixed and stirred evenly to obtain the water-based high adhesion water-resistant paint.

[0038] Wherein the halide salt, barium halide, cuprous halide complex ion [CuX 2 ] - The halogen element X in is a chlorine element; the valence of the cation in the ...

Embodiment 3

[0041] The invention provides a kind of preparation method of water-based high adhesion water-resistant paint comprising the following steps:

[0042] (1) Mix and react halogen salt, copper ion salt and sulfite according to the molar ratio of 3.2:1.8:1 for 1.4 hours, then add barium halide to the mixed solution and filter to remove the precipitate to obtain the cuprous halide complex ion [CuX 2 ] - solution, to [CuX 2 ] - Add stabilizer to the solution for later use;

[0043] (2) the mass components are 26 parts of polyurethane resin, 32 parts of water-based acrylic resin, 20 parts of epoxy resin, 1.6 parts of hydroxymethyl cellulose, 28 parts of monovalent alginate, 25 parts of water and stabilized [CuX 2 ] - The solutions are mixed and stirred evenly to obtain the water-based high adhesion water-resistant paint.

[0044] Wherein the halide salt, barium halide, cuprous halide complex ion [CuX 2 ] - The halogen element X in is a chlorine element; the valence of the cat...

PUM

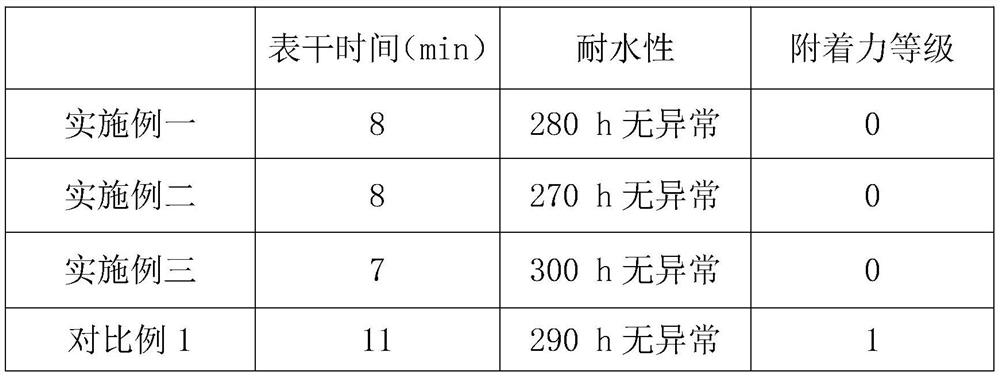

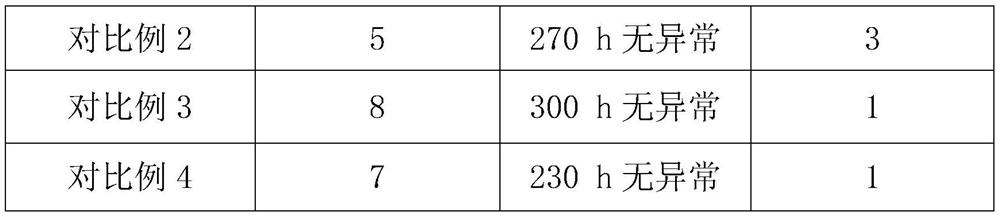

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com