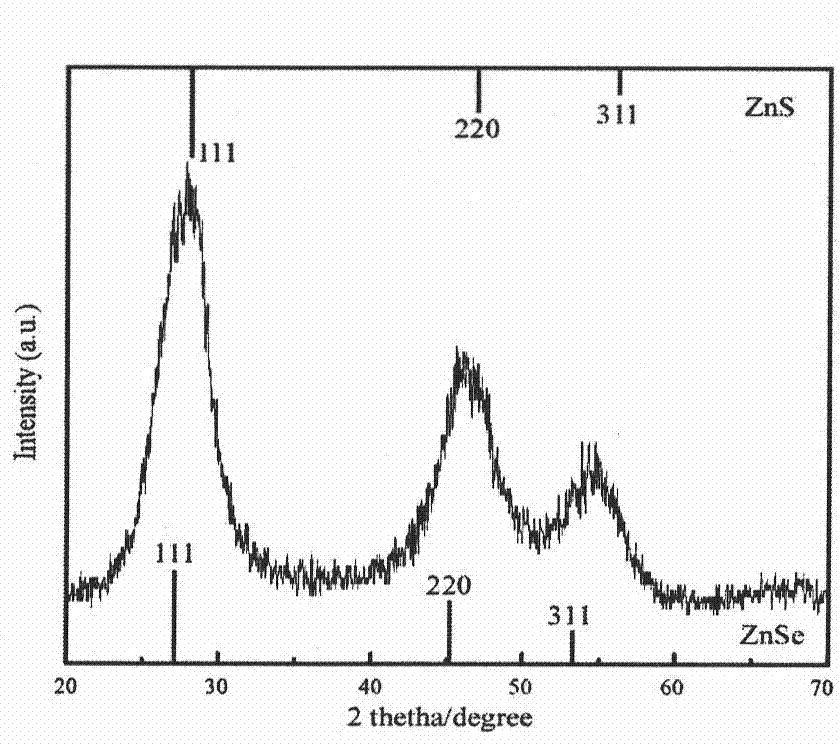

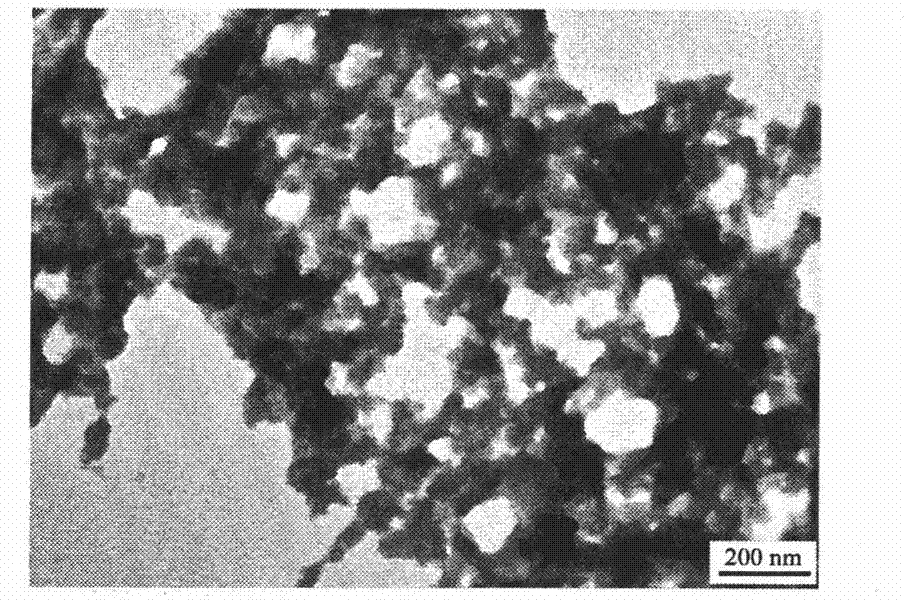

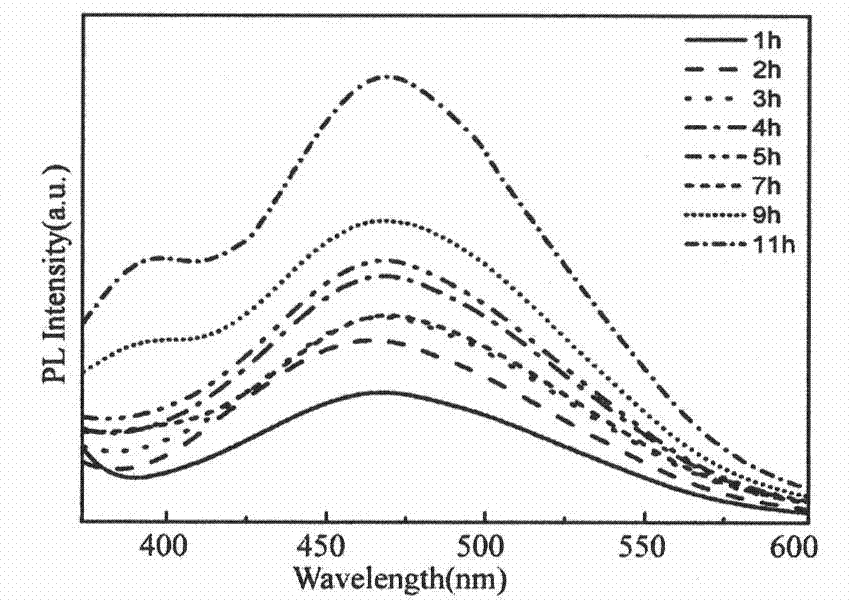

Method for synthesizing Pt: ZnSe(S) alloy nano crystal by aqueous phase process

An alloy nanocrystal, water phase technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as low fluorescence quantum yield, and achieve the effects of good water solubility, reduced toxicity and cost, and stable water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. First mix 0.439g of zinc acetate and 1.0614g of 3-mercaptopropionic acid, dilute to 50ml with water in a 250ml three-necked flask, mix and stir for 5 minutes.

[0032] 2. Add 10ml of 0.001M platinum tetrachloride solution to the solution in step 1, and continue stirring for 5 minutes.

[0033] 3. The pH of the solution in step 2 was adjusted to 8 with sodium hydroxide solution, at this time, argon gas was passed into the alkaline solution, and oxygen was removed by bubbling for 10 minutes to obtain an oxygen-free aqueous solution.

[0034] 4. Under the protection of argon, dissolve 0.079g of selenium powder and 0.0757g of sodium borohydride in 5ml of ultrapure water, heat to 40°C, and react for 30 minutes to prepare NaHSe stock solution.

[0035] 5. Quickly inject the NaHSe stock solution prepared in step 4 into the alkaline anaerobic aqueous solution prepared in step 3.

[0036] 6. The solution prepared in step 5 starts to heat up under the protection of an inert g...

Embodiment 2

[0039] 1. First mix 0.6585g of zinc acetate and 0.9553g of 3-mercaptopropionic acid, add water to a 250ml three-neck flask to dilute to 60ml, mix and stir for 10 minutes.

[0040] 2. Add 10ml of 0.002M platinum tetrachloride solution to the solution in step 1, and continue stirring for 5 minutes.

[0041] 3. The pH of the solution in step 2 was adjusted to 9 with sodium hydroxide solution, at this time, argon gas was passed into the alkaline solution, and oxygen was removed by bubbling for 20 minutes to obtain an oxygen-free aqueous solution.

[0042] 4. Under the protection of argon, dissolve 0.079g of selenium powder and 0.1136g of sodium borohydride in 1ml of ultrapure water, heat to 50°C, and react for 1 minute to prepare NaHSe stock solution.

[0043] 5. Quickly inject the NaHSe stock solution prepared in step 4 into the alkaline anaerobic aqueous solution prepared in step 3.

[0044] 6. The solution prepared in step 5 starts to heat up under the protection of an inert gas...

Embodiment 3

[0047] 1. First mix 1.0975g of zinc acetate and 1.0614g of 3-mercaptopropionic acid, dilute to 70ml with water in a 250ml three-necked flask, mix and stir for 15 minutes.

[0048] 2. Add 10ml of 0.004M platinum tetrachloride solution to the solution in step 1, and continue stirring for 5 minutes.

[0049] 3. Adjust the pH of the solution in step 2 to 9.5 with sodium hydroxide solution. At this time, nitrogen gas is passed into the alkaline solution, and oxygen is removed by bubbling for 15 minutes to obtain an oxygen-free aqueous solution.

[0050] 4. Under nitrogen protection, dissolve 0.079g of selenium powder and 0.1514g of sodium borohydride in 20ml of ultrapure water, heat to 80°C, and react for 5 minutes to prepare NaHSe stock solution.

[0051] 5. Quickly inject the NaHSe stock solution prepared in step 4 into the alkaline anaerobic aqueous solution prepared in step 3.

[0052] 6. The solution prepared in step 5 starts to heat up under the protection of an inert gas, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com