Strongly waterproof antistatic fabric and preparation method thereof

An anti-static, fabric technology, applied in chemical instruments and methods, textile, lamination, etc., can solve the problems of dust and dander on the cloth surface, affecting the efficiency of clothing production, affecting the appearance, etc., to solve the problem of dander and dander The effect of dust, excellent antistatic performance and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A strong waterproof and antistatic fabric, including warp yarns and weft yarns, the warp yarns and weft yarns are all made of P50D / 72F SDDTY polyester high elastic yarn, the warp yarns and weft yarns are plain weaved into a gray cloth, and the gray cloth is dyed and finished to obtain a semi-finished cloth , the semi-finished cloth is compounded with a TPU transparent film through hot melt adhesive, and the finished cloth is obtained after ripening.

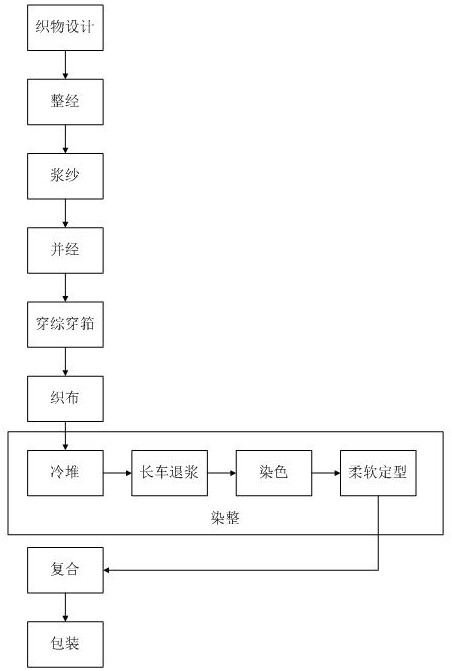

[0035] Such as figure 1 As shown, the present embodiment also provides a method for preparing the above-mentioned strong waterproof and antistatic fabric, comprising the following steps:

[0036] S1. Fabric design: select the warp and weft raw materials; design the warp density, weft density, width and square meter weight of the gray fabric, and calculate the total warp number of the pan head, the machine weft density and reed number, and the total warp root Number = gray cloth warp density × gray cloth width ÷ 2.54, mach...

Embodiment 2

[0045] A kind of strong waterproof antistatic fabric, and its difference with embodiment one is: (1) the meter weight of described warp yarn is 43.2g, and the meter weight of described weft yarn is 39.2g; (2) the warp density of described gray cloth is 114T, the weft density of the gray cloth is 97T, the width of the gray cloth is 173.2cm, and the square meter weight of the gray cloth is 49G / m 2 (3) the warp density of the finished cloth is 130T, the weft density of the finished cloth is 110T, the width (in the needle) of the finished cloth is 148cm, and the square meter weight of the finished cloth is 64G / m 2 .

[0046] In this embodiment, the dyeing and finishing includes cold stacking, long car desizing, overflow dyeing, dehydration and soft setting in sequence.

[0047] Such as figure 1 As shown, this embodiment also provides a preparation method of the above-mentioned strong waterproof and antistatic fabric, which is different from Embodiment 1 in that: in step S1, the ...

Embodiment 3

[0062] Such as figure 1 Shown, a kind of preparation method of above-mentioned strong waterproof and antistatic fabric, its difference with embodiment two is: in step S7:

[0063] Cold pile: first configure the first desizing solution, prepared by water volume of caustic soda 60g / L, desizing agent TF-127: 20g / L, scouring emulsifier 120C: 20g / L and penetrant TF-JFC: 5g / L 300L of the first desizing solution is placed in the trough; then the first desizing solution is raised to 60°C; then the unrolled gray cloth passes through the trough evenly, and then is fully wetted by the rolling machine and then rolled into a roll , rotate at 10 revolutions / min, and stack at room temperature for 24 hours.

[0064] Among them, caustic soda is provided by Cangzhou Yuanlu Chemical Products Co., Ltd. in Hebei, desizing agent TF-127, scouring emulsifier 120C and penetrating agent TF-JFC are all provided by Zhejiang Transfarm Group Co., Ltd. In this embodiment, the desizing effect is improved b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com