Sound insulation and heat preservation wall module and fabricated building wall having same

A technology for sound insulation and wall body, which is applied in the directions of heat insulation, sound insulation, building components, etc., can solve the problems of decreased practicability of the overall structure, inconvenient installation and disassembly of the overall structure, etc. The effect of connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

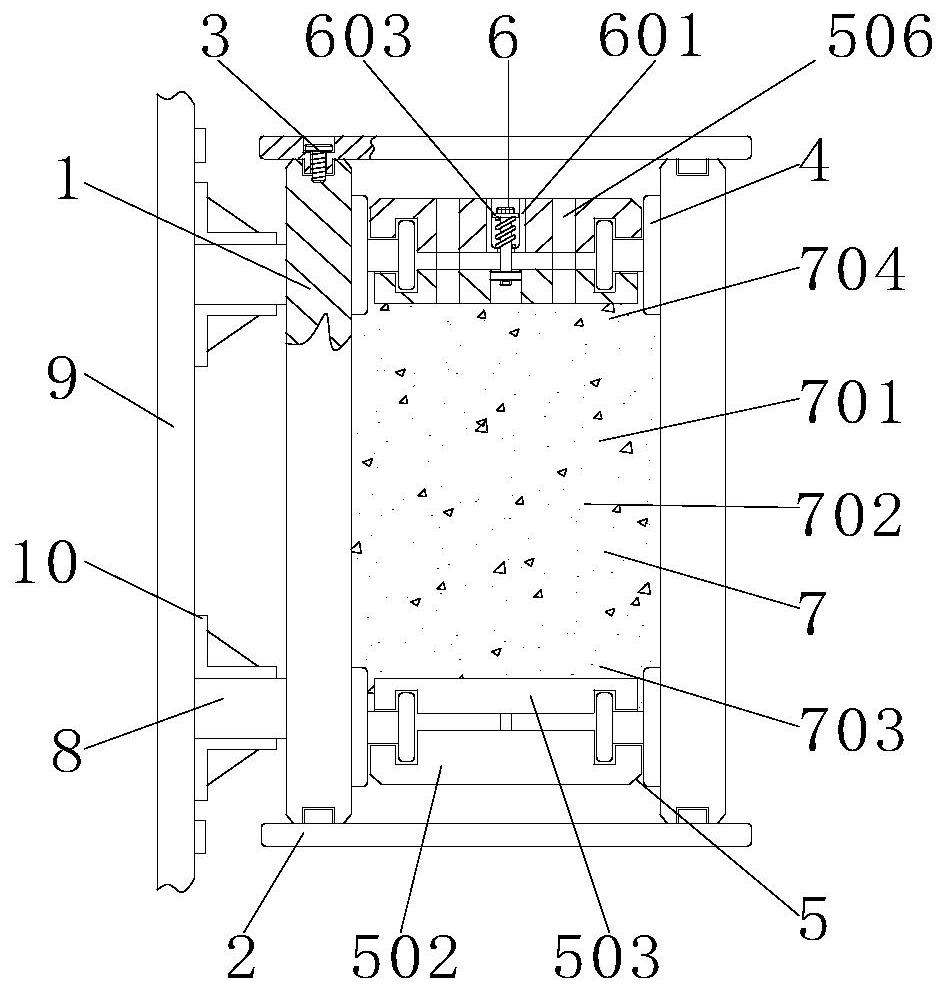

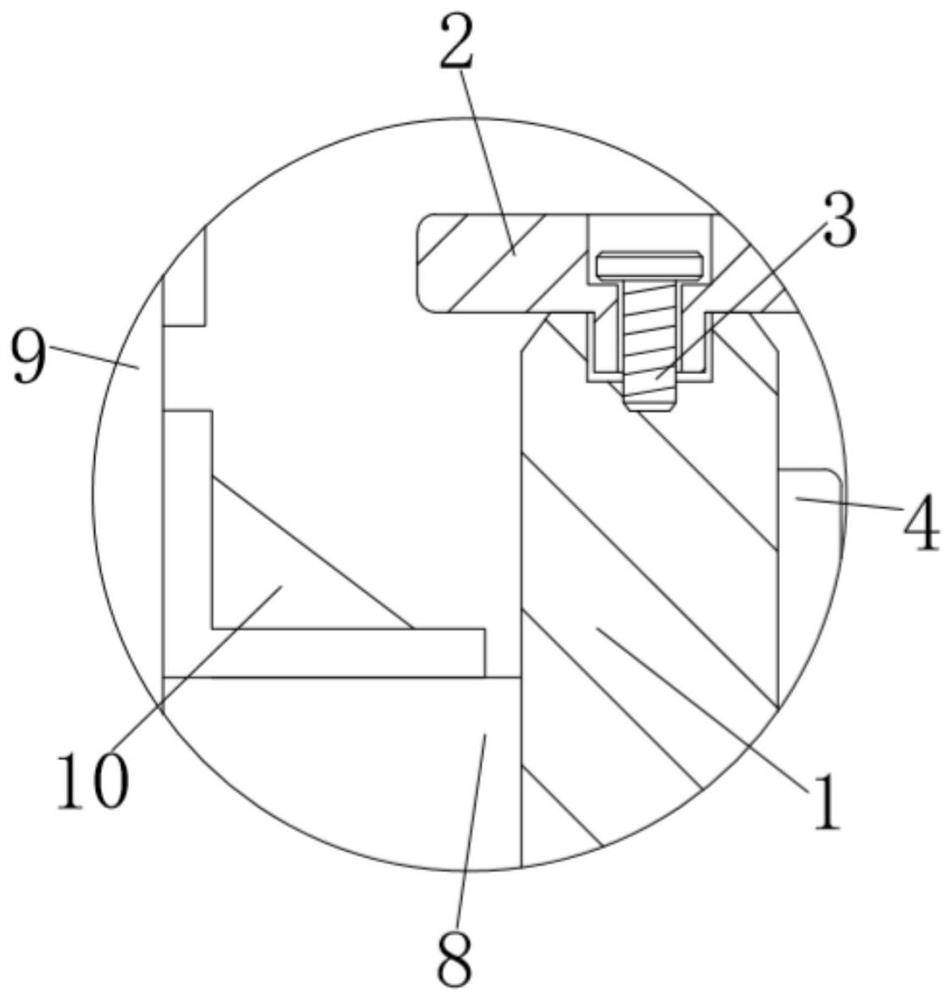

[0044]A wall module for sound insulation and heat preservation, comprising a vertical plate 1, a horizontal plate 2, bolts 3 and a backing plate 4, the upper and lower ends of the two vertical plates 1 are equipped with horizontal plates 2, and the left and right sides of the two horizontal plates 2 Both are threadedly connected with the vertical plate 1 through the bolt 3, and the horizontal plate 2 is fixed on the top of the vertical plate 1 through the bolt 3. The outer wall of the vertical plate 1 is fixedly connected with the backing plate 4, and the outer wall of the backing plate 4 is equipped with a connecting mechanism 5. Mechanism 5 comprises T-shaped plate 501, the first clamping plate 502, the second clamping plate 503, through hole 504 and collar 505, and the outer walls of four T-shaped plates 501 are all fixedly connected with backing plate 4, and the T-shaped plate 501 One side is pasted with a first clip 502, and the other side of the T-shaped plate 501 is past...

Embodiment 2

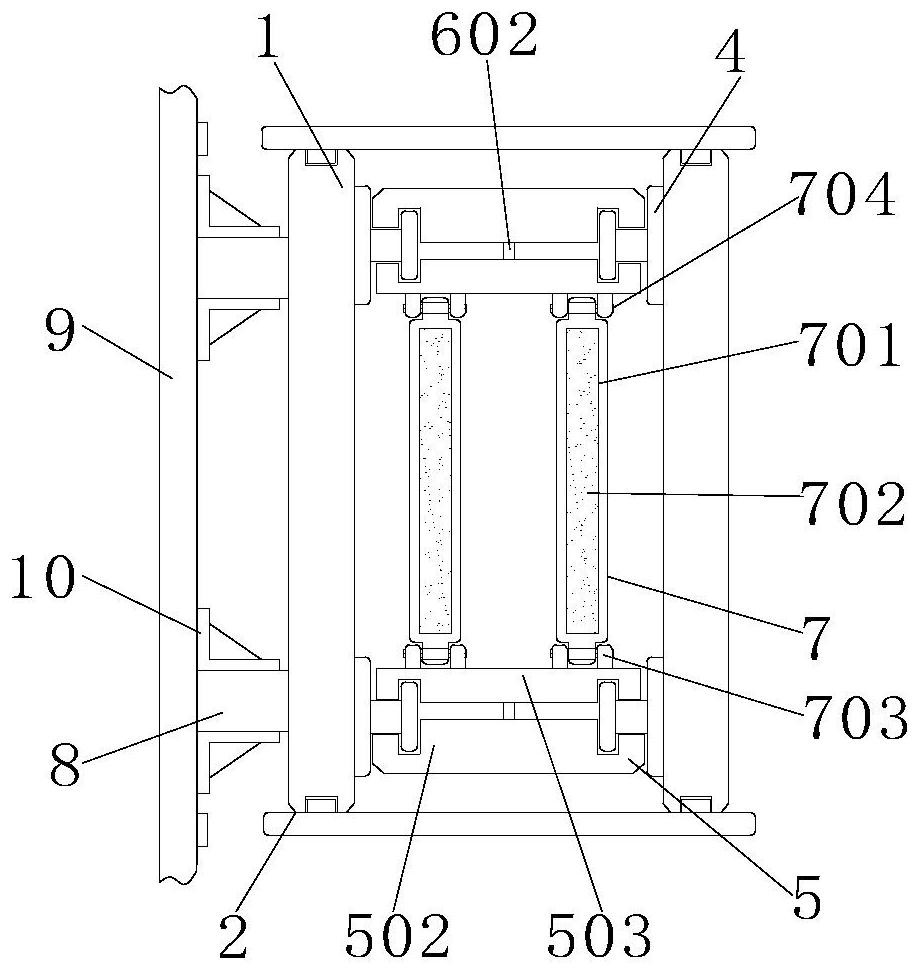

[0047] As an option, see figure 1 , 2 and 5, the wall module of sound insulation and heat preservation, the left end of the left vertical plate 1 is fixedly connected with a connecting plate 8, and the left ends of the two connecting plates 8 are fixedly connected with a mounting plate 9, and the mounting plate 9 is used to connect the whole mechanism with the outside connection, a reinforcing plate 10 is fixedly connected between the mounting plate 9 and the connecting plate 8, and the reinforcing plate 10 increases the connection strength between the mounting plate 9 and the connecting plate 8, and a fixing mechanism 6 is installed inside the first clamping plate 502, and the fixing mechanism 6 includes a sleeve 601, a vertical rod 602, a top plate 603, a rotary knob 604 and a spring 605, the outer walls of the two sleeves 601 are fixedly connected to the first clamping plate 502, and the vertical rod 602 is sleeved inside the sleeve 601, The bottom end of the vertical rod ...

Embodiment 3

[0050] As an option, see figure 1 , 2 And 6, the wall module of sound insulation and heat preservation, the outer wall of the first clamping plate 502 is fixedly connected with the sound insulation mechanism 7, and the sound insulation mechanism 7 includes the connection frame 701, the sound insulation cotton 702, the card seat 703 and the insertion rod 704, the two connection frames 701 The interior is filled with soundproof cotton 702, the upper and lower ends of the connection frame 701 are fixedly connected with a card seat 703, and the outer wall of the second card plate 503 is symmetrically fixed with a card seat 703, and the outer wall of the card seat 703 is connected to the second card plate 503. The inserting rod 704 is sleeved inside the card holder 703 , and the outer wall of the inserting rod 704 is closely attached to the card holder 703 and the connection frame 701 , and the card holders 703 are symmetrically distributed with respect to the second card board 503...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap