Vibration digging structure for sugar beet harvester

A harvester and sugar beet technology, applied in excavating harvesters, harvesters, applications, etc., can solve the problems of beet slippage and inability to dig up beets, and achieve the effects of reducing economic losses, improving harvest rate, and avoiding missed digging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

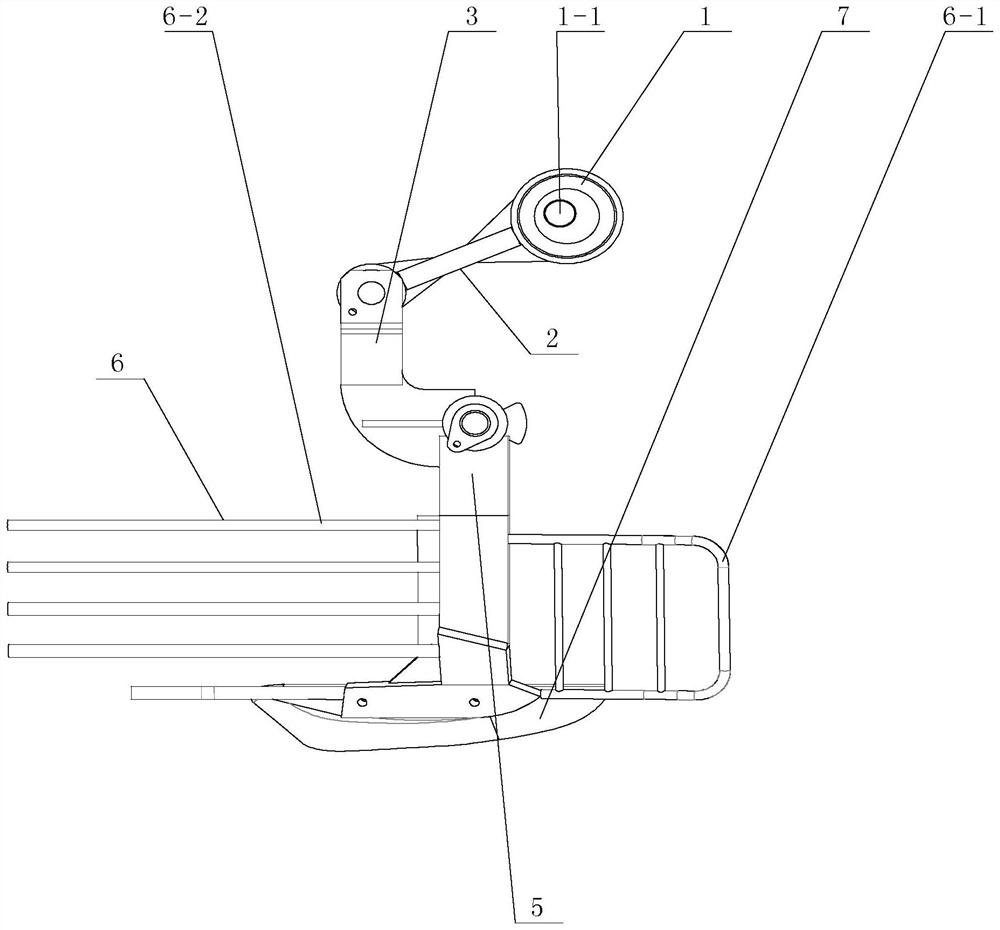

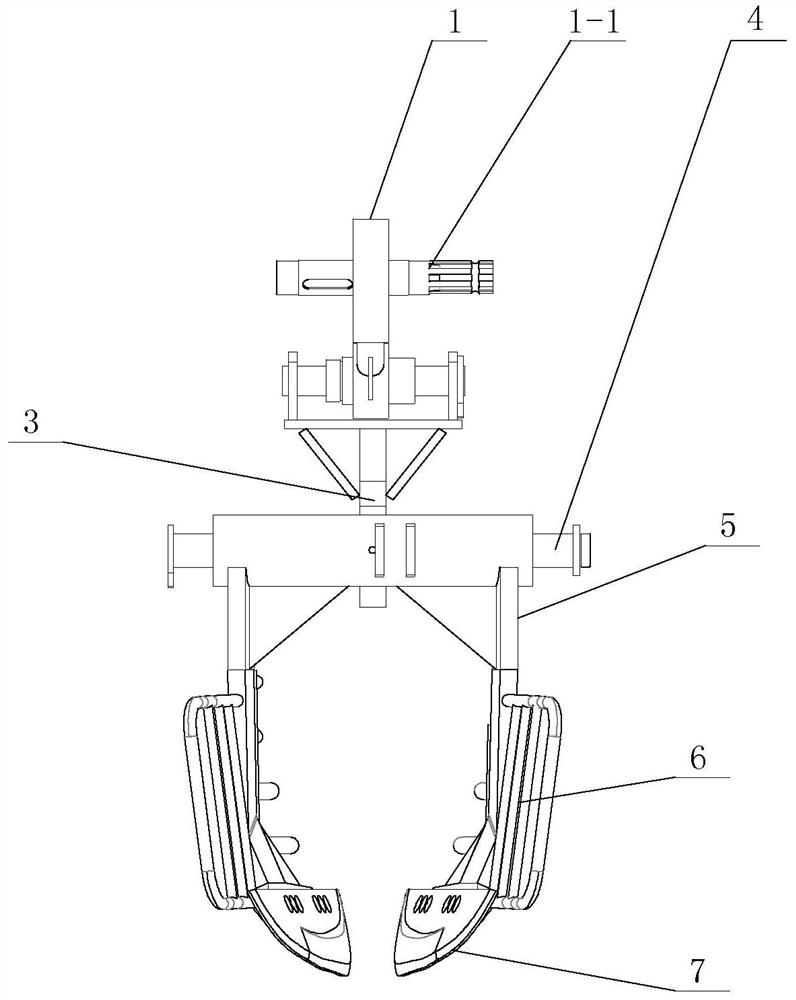

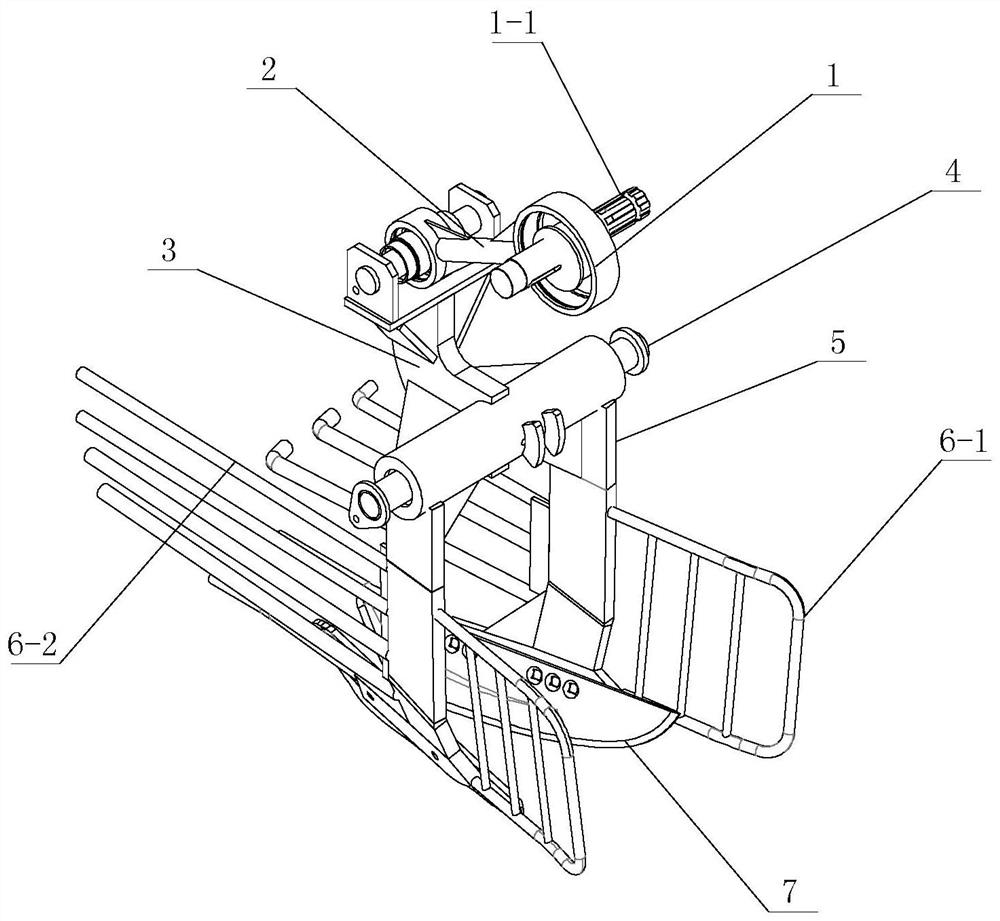

[0013] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a kind of vibrating excavation structure for sugar beet harvester described in this embodiment includes an eccentric wheel assembly, a share handle assembly and two root excavation mechanisms, the eccentric wheel assembly is connected with the power output shaft of the traction device, and the The eccentric wheel assembly is connected to the upper end of the shank assembly, and the two root digging mechanisms are installed side by side at the lower end of the shank assembly.

[0014] The vibration frequency of the present invention is 540 Hz, the vibration amplitude is ±7 degrees, and the penetration depth is 10-15 cm.

specific Embodiment approach 2

[0015] Specific implementation mode two: combination Figure 1 to Figure 3 Describe this embodiment, the eccentric wheel assembly of a kind of vibration excavation structure for sugar beet harvester in this embodiment includes a cam 1 and a connecting arm 2, the camshaft 1-1 of the cam 1 is eccentrically arranged, and the camshaft 1- 1 is connected with the power output shaft of the traction equipment, the cam 1 is connected with one end of the connecting arm 2, and the other end of the connecting arm 2 is connected with the upper end of the shank assembly.

[0016] In this embodiment, the eccentric distance of the camshaft 1-1 is ±10mm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination Figure 1 to Figure 3 Describe this embodiment, the described share handle assembly of a kind of beet harvester vibration digging structure described in this embodiment comprises share handle 3, share handle rotating shaft 4 and two drive handles 5, the upper end of share handle 3 and connecting arm 2, the lower end of the share handle 3 is connected with the share handle rotating shaft 4, two driving handles 5 are arranged side by side, and the upper end of each driving handle 5 is connected with the sharing handle rotating shaft 4, and the lower end of each driving handle 5 All are connected with one described root excavating mechanism. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com