Full-automatic argon arc welding machine

A argon arc welding machine, fully automatic technology, applied in arc welding equipment, electrode characteristics, welding equipment and other directions, can solve the problems of inability to weld materials with different structures, single welding main body, unable to meet production needs, etc. performance, improve stability and improve welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

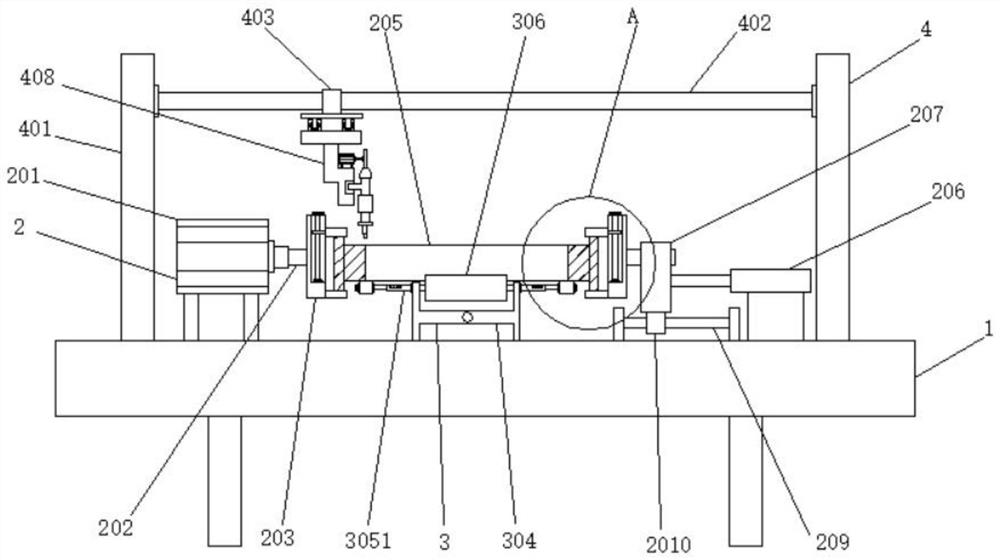

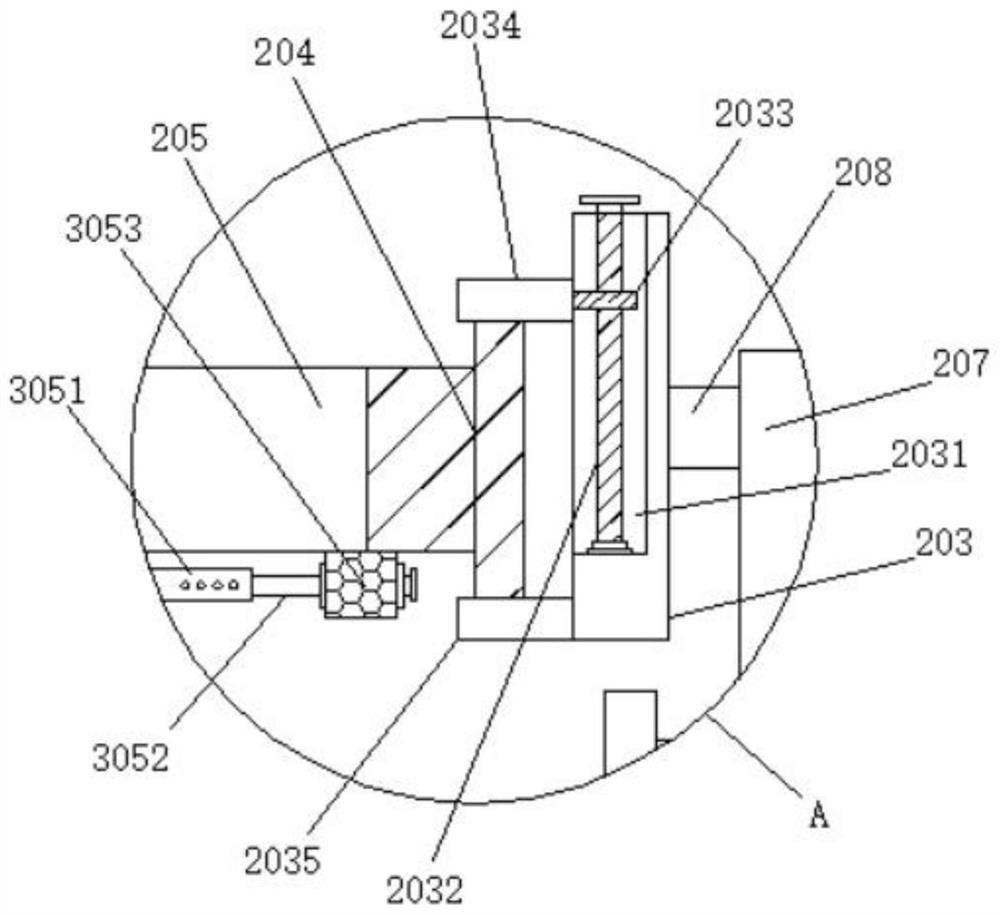

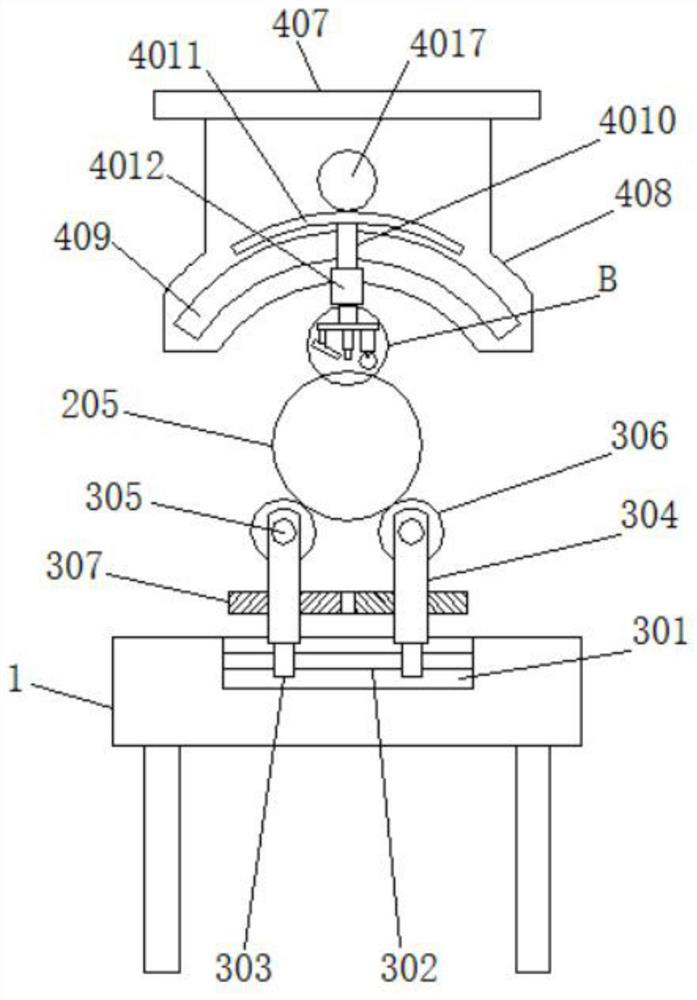

[0031] see Figure 1-6 , a full-automatic argon arc welding machine, including a base 1, the surface of the base 1 is respectively equipped with an adjusting mechanism 2, a stabilizing mechanism 3 and a welding mechanism 4, and the inside of the adjusting mechanism 2 includes one fixed on one side of the top surface of the base 1 No. motor 201, and the output end of No. 1 motor 201 is connected with No. 1 rotating shaft 202, and the other end of No. 1 rotating shaft 202 is connected with fixture 203 by welding, and the surface of fixture 203 is connected with first weldment 204, and the first weldment The other end of 204 is fitted with a second weldment 205, the other side of the top surface of the base 1 is fixedly connected with a hydraulic rod 206, and the other end of the hydraulic rod 206 is fixedly connected with a vertical plate 207, and the vertical plate 207 body is laterally movably connected with a The second rotating shaft 208, and the other end of the second rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com