Environment-friendly cosmetic glass packaging bottle

A glass packaging, green and environmentally friendly technology, applied in packaging, transportation, packaging, bottles, etc., can solve the problems of inability to protect transparent glass packaging bottles, easy scratches on transparent glass packaging bottles, and easy deterioration of cosmetics, etc., so as to be easy to promote Implementation, convenient classification and access, and ingenious design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

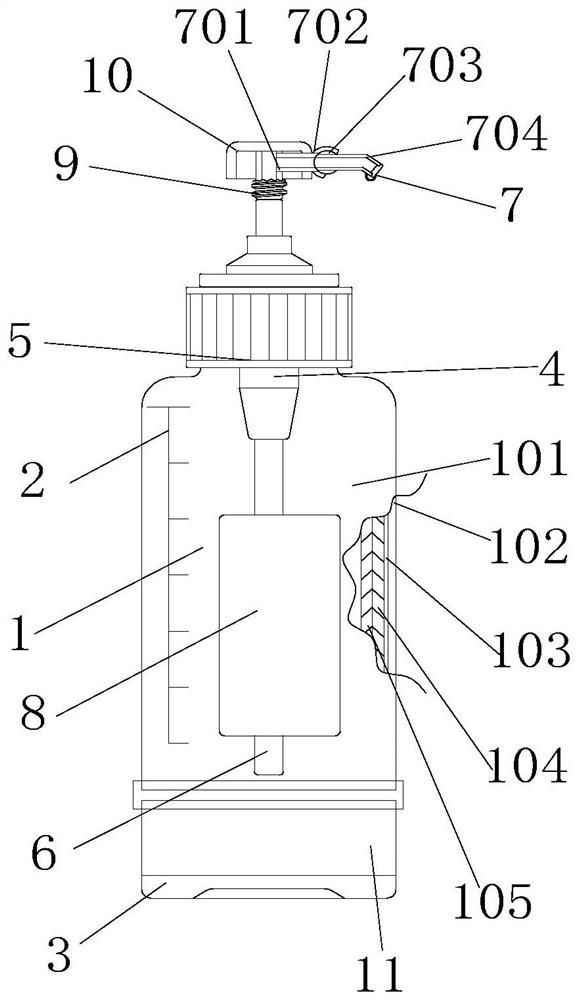

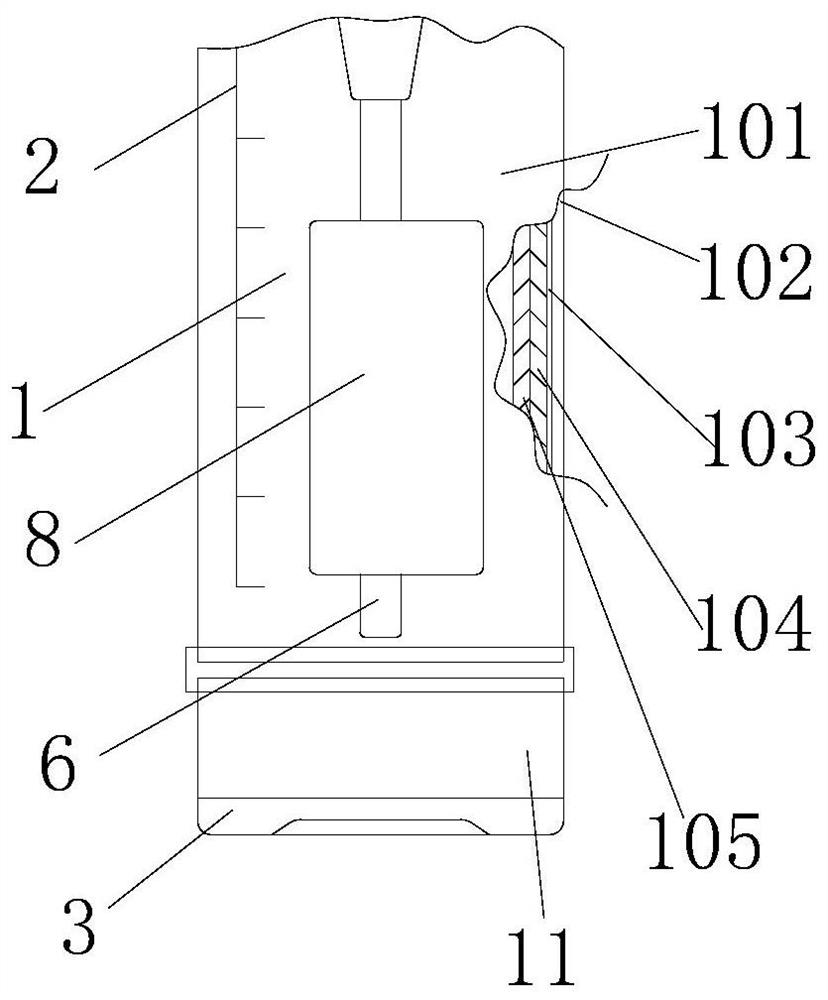

[0038] A green and environmentally friendly cosmetic glass packaging bottle, including a main bottle body 1, the front of the main bottle body 1 is processed with a scale line 2, the scale line 2 is used to check the cosmetic content in the bottle, and the bottom of the main bottle body 1 is fixedly connected with a non-slip base 3. The anti-skid base 3 is made of rubber, and the top bottle mouth of the main bottle body 1 is fitted with a push pump body 4 in the gap. The outer wall of the push pump body 4 is rotatably connected with a threaded cap 5, and the outer wall of the threaded cap 5 is processed with convex ribs. And the internal thread of the inner wall of the threaded cap 5 is tightly engaged with the external thread provided at the top bottleneck of the main bottle body 1, so that the design can ensure the sealing in the bottle, and it is convenient to rotate and disassemble the pressing pump body 4. The inner wall of the threaded cap 5 is threadedly connected with t...

Embodiment 2

[0043] As an option, see figure 1 , 3 And 4, the cosmetic glass packaging bottle of green environmental protection, main bottle body 1 comprises inner base layer 101, PET protective film 102, adhesive bonding layer 103, heat insulation coating 104 and anti-ultraviolet coating 105, the outside of inner base layer 101 is provided with PET protective film 102, PET protective film 102 is made by shearing of colorless environmental protection PET film, and the shape when PET protective film 102 surrounds fits with the shape of main bottle body 1, design like this can protect the outer wall of main bottle body 1 To play a protective role, the inner side of the PET protective film 102 is provided with an adhesive layer 103, the adhesive layer 103 is applied to the inner side of the PET protective film 102, and the inner side of the adhesive layer 103 is provided with a heat-insulating coating 104 for heat insulation. The coating 104 is a barrier heat-insulating paint, which is a pai...

Embodiment 3

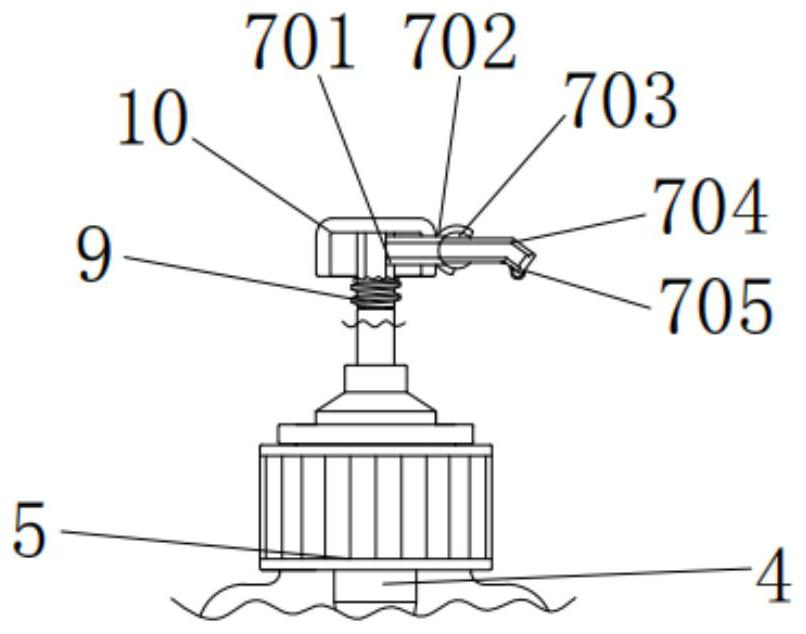

[0046] As an option, see figure 1 , 2 , 5 and 6, green and environmentally friendly cosmetic glass packaging bottles, the right side of the vertical tube 9 is provided with a discharge assembly 7 and a pressing assembly 7 includes a horizontal thick tube 701, a ball seat 702, a circular ball 703, a horizontal thin tube 704, rubber Blocking block 705, plastic stay cord 706 and ear-shaped support 707, the left end of horizontal thick tube 701 communicates with the right end top of standpipe 9, the outer wall left side of horizontal thick tube 701 penetrates and is fixedly connected to the right end of pressing round cover 10, horizontally The right end of the thick tube 701 is provided with a ball seat 702, and the right end face of the ball seat 702 is arranged obliquely. This design can limit the rotation angle of the circular ball 703 and the horizontal thin tube 704, and the ball seat 702 The left end communicates with the right end of the horizontal thick tube 701, the inn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap