Cement-based self-leveling mortar and preparation method thereof

A self-leveling mortar and cement-based technology, which is applied in the field of self-leveling mortar, can solve problems such as performance conflicts and unsuitability for waterproofing, and achieve the effects of strengthening compactness, improving compactness, and high impervious pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

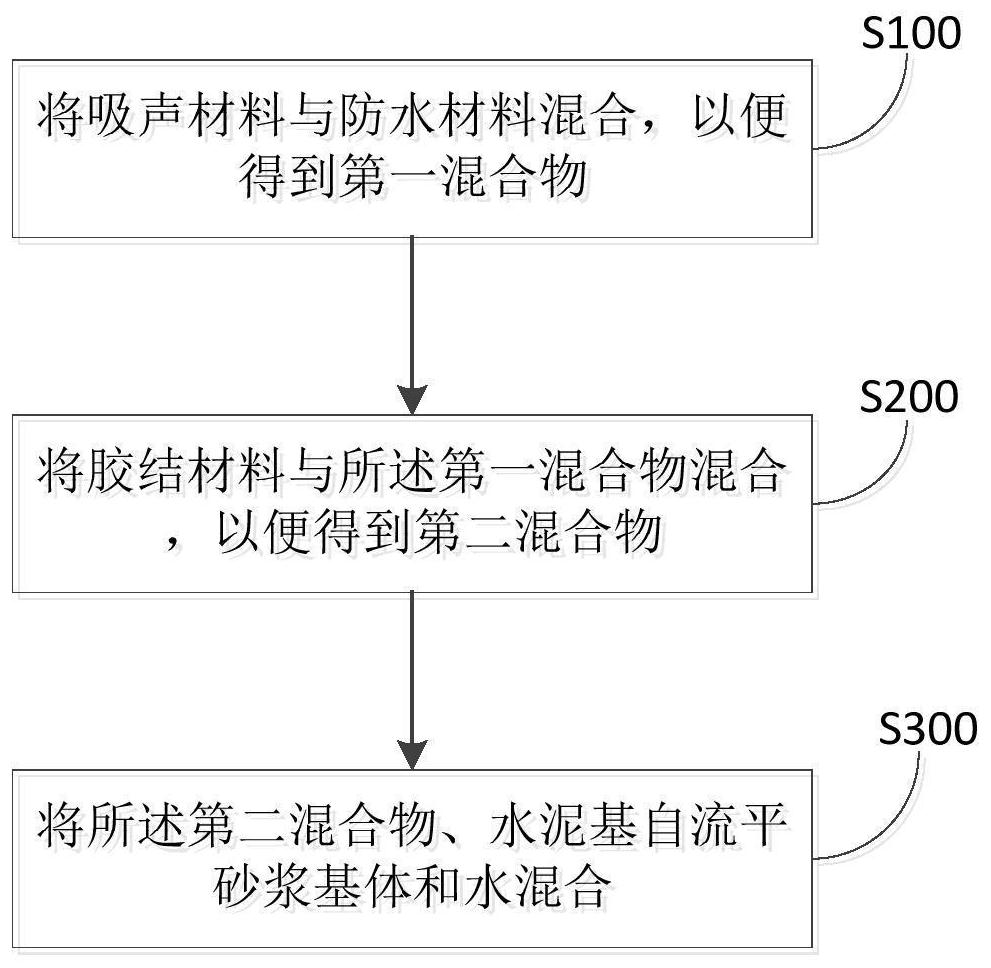

Method used

Image

Examples

preparation example Construction

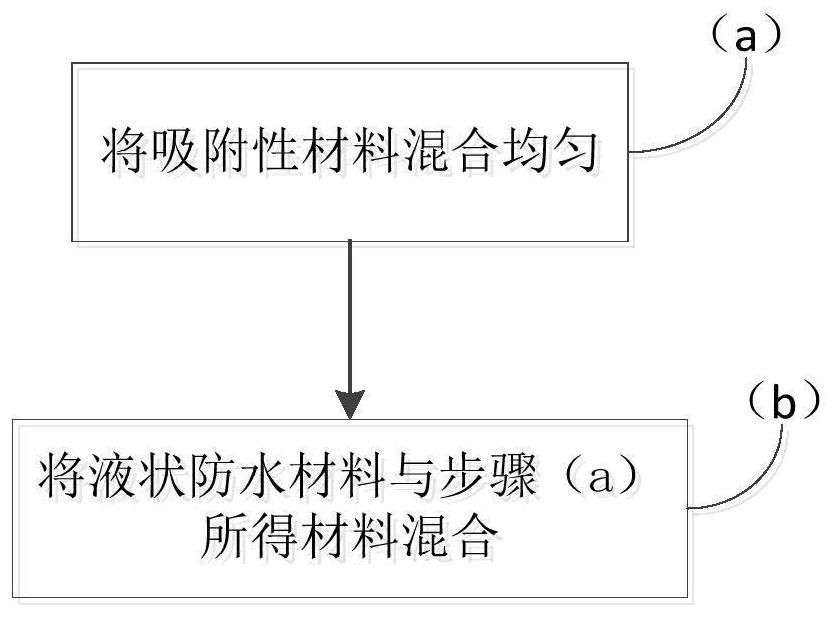

[0055] Further, for the preparation method of the above-mentioned waterproof material, refer to the attached figure 2 , including the following steps:

[0056] (a) Mix the adsorbent material evenly

[0057] In this step, if the adsorptive material contains one material, it is not necessary to mix, and if it contains two or more materials, it needs to be mixed uniformly.

[0058] (b) mixing the liquid waterproof material with the material obtained in step (a)

[0059] In this step, the specific way of mixing the liquid waterproof material with the material obtained in step (a) is not particularly limited, and those skilled in the art can choose according to actual needs, and the liquid waterproof material can be added to the material obtained in step (a) The material obtained in step (a) can also be added to the liquid waterproof material. As a preferred solution, the liquid waterproof material is added to the material obtained in step (a) in batches for several times, and m...

Embodiment 1

[0068] In parts by weight, 35 parts of Wacker Chemical BS16 (potassium methyl silicate), 20 parts of Dow Corning produce OF6403 (organosiloxane) are added in batches to 45 parts of 3000 mesh fumed silica, Mix evenly in a high-frequency mixer until powdery, to obtain the waterproof functional material a;

[0069] In parts by weight, mix 45 parts of hollow glass microspheres of 40-70 mesh, 20 parts of rubber powder of 100 mesh, and 35 parts of mica of about 50 mesh to a uniform state to obtain the sound-absorbing material b;

[0070] In parts by weight, 15 parts of the prepared waterproof functional material a were added in batches to 65 parts of the prepared sound-absorbing material b, mixed to a uniform material, and then 10 parts of BASF S400 acrylic emulsion, 10 parts of industrial-grade sodium silicate aqueous solution was stirred in a low-speed mixer until it was dry and uniform to obtain a sound-proof and waterproof functional mixture A;

[0071] In parts by weight, a se...

Embodiment 2

[0078] In parts by weight, 15 parts of chemical store industrial grade potassium methyl silicate, 40 parts of Wacker chemical BS28N organosiloxane were added in batches to 25 parts of 3000 mesh fumed silica, 20 parts of 1500 Mesh diatomite, mixed uniformly in a high-frequency mixer until powdery, to obtain waterproof functional material a;

[0079] In parts by weight, 35 parts of 40-70 mesh hollow glass microspheres, 30 parts of 100 mesh rubber powder, 15 parts of mica of about 50 mesh, and 20 parts of vermiculite of about 40 mesh are mixed to a uniform state. Obtain the sound-absorbing material b;

[0080] In parts by weight, add 25 parts of the prepared waterproof functional material a to 55 parts of the prepared sound-absorbing material b in batches, mix until the material is uniform, and then add 8 parts of Wacker Chemie 707K ethylene - polyvinyl acetate emulsion, 12 parts of commercially available industrial grade sodium silicate aqueous solution, stirred in a low-speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com