A kind of fiber reinforced silicon boron nitrogen composite material and preparation method thereof

A fiber-reinforced, composite material technology, applied in the field of fiber-reinforced silicon boron nitride composite materials, can solve the problem of inability to remove surface solidification, and achieve the effect of promoting the impregnation-curing-cracking process, with less damage and a simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention provides a kind of preparation method of fiber-reinforced silicon-boron-nitrogen composite material in the first aspect, and described preparation method comprises the following steps:

[0024] (1) Using silicon boron nitrogen fiber to prepare a fiber preform, and then using polysilaborazane to impregnate the fiber preform to obtain an impregnated fiber preform;

[0025] (2) Carry out initial curing reaction to the impregnated fiber preform described in step (1) at the first curing temperature, and when the polysilaborazane changes from a fluid state to a semi-fluid state, continue to cure at the first curing temperature. Keeping the temperature until the polysilaborazane is jelly-like to obtain an initially cured fiber preform with a polysilaborazane cured product on the surface;

[0026] (3) removing the cured polysilaborazane on the surface of the initially cured fiber preform, and then performing a secondary curing reaction on the fiber preform...

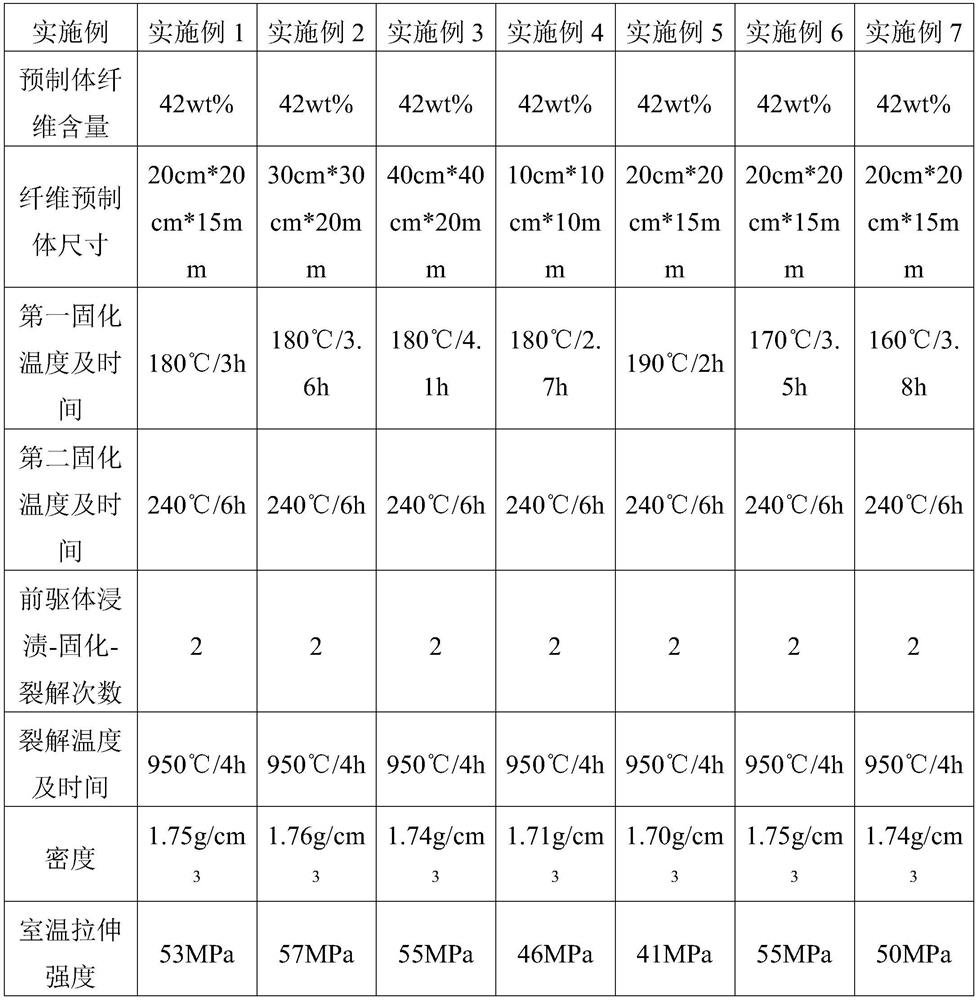

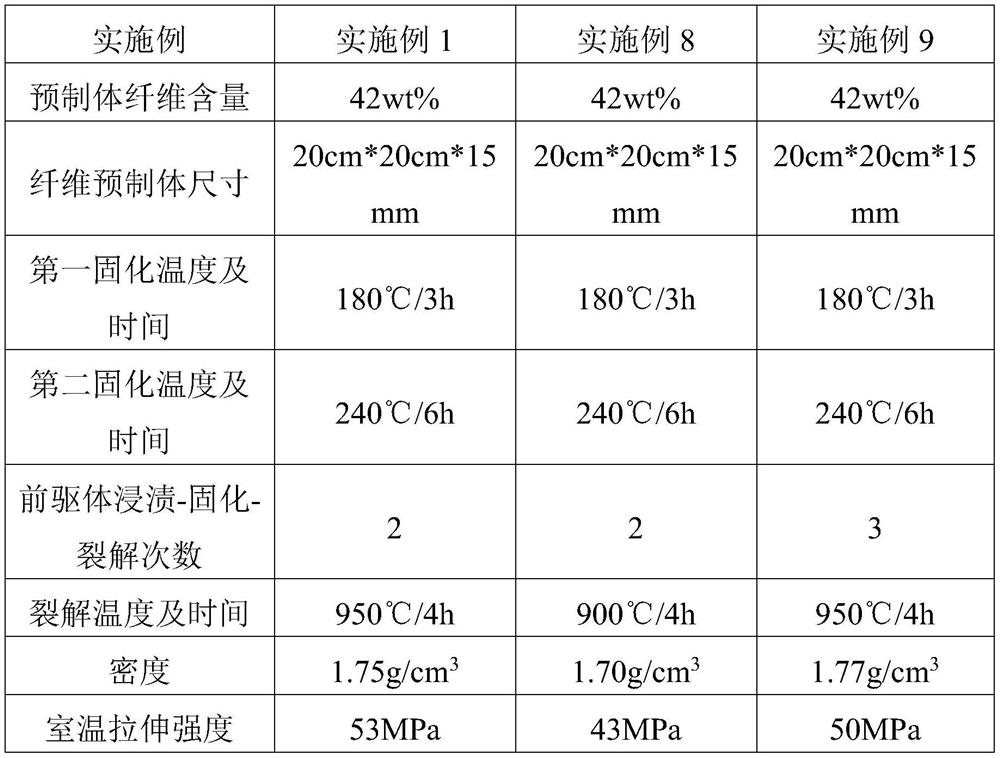

Embodiment 1

[0041] The silicon boron nitrogen fiber is processed into a fiber preform with a fiber volume content of 42% by weaving, which is used in the subsequent impregnation step, and the size of the fiber preform is 20cm*20cm*15mm. Vacuum impregnation method is used to impregnate the fiber preform, put the fiber preform fully impregnated with polysilaborazane into the oven, select 180°C as the first curing temperature, and react for 3 hours, and wait for the polysilaborazane cured product to flow When it becomes semi-fluid, continue to keep warm for 5 minutes. After taking it out, manually remove the jelly-like solidified material on the surface of the fiber preform, then put it into the oven, select 240°C as the second curing temperature, and keep it warm at this curing temperature for 6 hours. Make the polysilaborazane fully cured, and then take it out of the oven. At this time, the surface of the fiber preform is not covered with excess polysilaborazane cured material, and the poly...

Embodiment 2

[0043] Embodiment 2 is basically the same as Embodiment 1, except that the size of the fiber preform is 30cm*30cm*20mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com