Green and environment-friendly processing method of high-quality natural colored silk fabric

A colored silk, green and environmentally friendly technology, applied in the direction of fabrics, textiles, animal fibers, etc., can solve the problems of poor hand feeling, low work efficiency, yellowing of fabrics, etc., and achieve simple glue fixing process, no formaldehyde release, and low economic cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

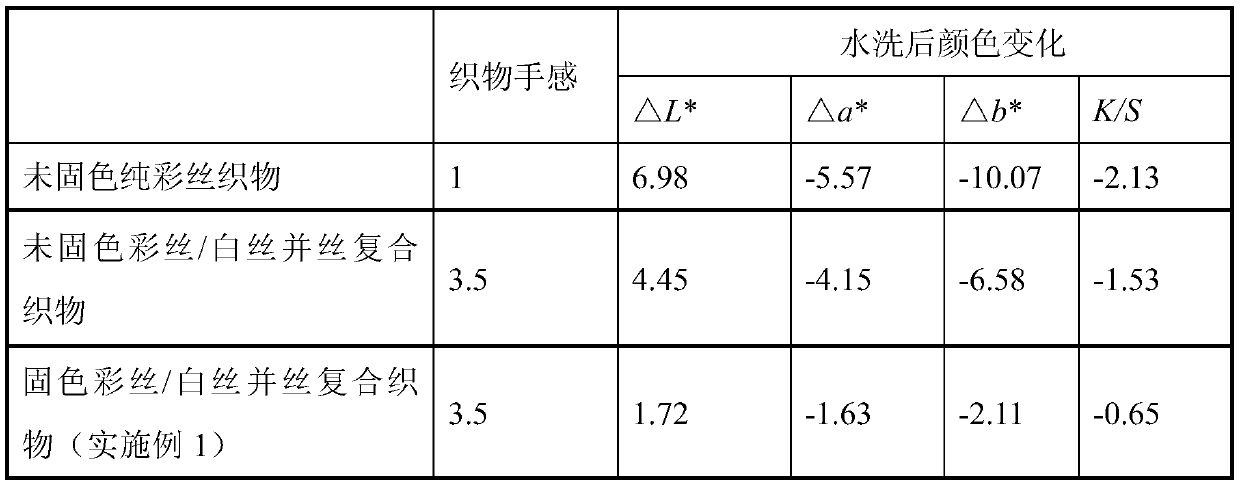

Embodiment 1

[0029] Embodiment 1, a kind of green environmental protection processing method of high-quality natural color silk fabric, comprises padding, winding into cylinder, cold pile, doubling, weaving and refining, promptly, carries out following steps successively:

[0030] S1. Preparation of color-fixing treatment solution and color-fixing treatment:

[0031] 1.1, prepare color-fixing treatment liquid: deploy the aqueous solution that contains the phytic acid of 0.25g / L and the penetrant JFC of 1.8g / L (that is, contain 0.25g phytic acid and 1.8g penetrant JFC in every liter of aqueous solution water, remaining The amount is water), and the pH is adjusted to 7-9 (for example, about 8.14) by using a sodium hydroxide solution with a concentration of 10g / L, and the color fixing treatment solution is kept at 30°C (this temperature is maintained throughout the wetting process).

[0032] 1.2. Natural colored silk strands (select natural colored silk strands that have been reeled and shake...

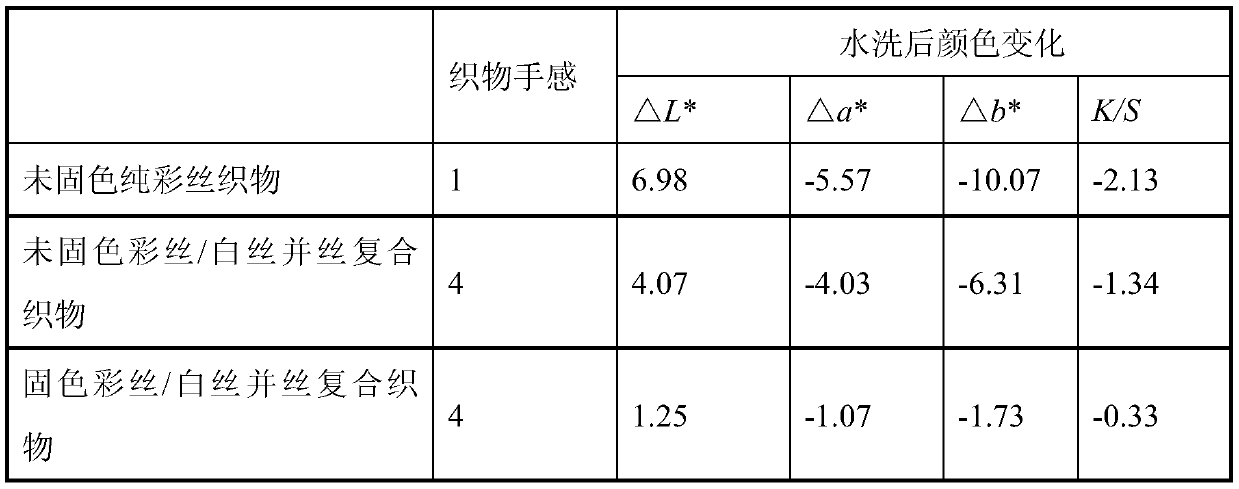

Embodiment 2

[0045] Embodiment 2, a kind of green environmental protection processing method of high-quality natural color silk fabric:

[0046] S1. Preparation of color-fixing treatment solution and color-fixing treatment:

[0047] 1.1. Preparation of color-fixing treatment solution: Prepare an aqueous solution containing 105.6g / L of phytic acid and 4.5g / L of penetrant JFC, and adjust the pH to 3-5 with a concentration of 10g / L of sodium hydroxide solution (for example, about 3.37), the color-fixing treatment solution is heated to 55°C and kept warm.

[0048] 1.2. Control the bath ratio of natural colored silk strands / color-fixing treatment solution to 1:30 (kg / L), immerse natural colored silk strands in the color-fixing treatment solution, take out the colored silk after it is completely wet, press the liquid Roll out the excess color-fixing treatment solution with a rate of more than 40%, then wind the natural colored silk strands with liquid into a tube, place it in a cold stack for 1...

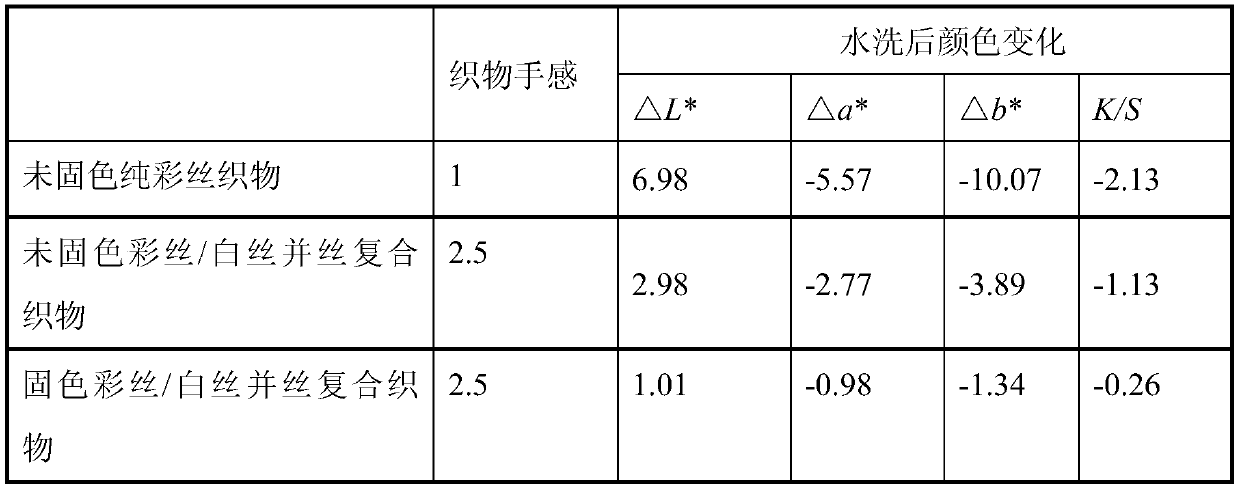

Embodiment 3

[0056] Embodiment 3, a kind of green environmental protection processing method of high-quality natural colored silk fabric, comprises the steps of winding into a cylinder, dipping, cold stacking, doubling, weaving and refining, that is, the following steps are carried out in sequence:

[0057] S1. Preparation of color-fixing treatment solution and color-fixing treatment:

[0058] 1.1. Prepare the color-fixing treatment solution, prepare an aqueous solution containing 2.5g / L phytic acid and 9.0g / L penetrant JFC, and adjust the pH to 5-7 with a 10g / L sodium hydroxide solution (for example, about 6.8), the color-fixing treatment solution is heated to 85°C and kept warm.

[0059] 1.2. After the natural colored silk strands are reeled (i.e. colored silk bobbins), soak them in the color-fixing treatment solution at a bath ratio of 1:30 (kg / L), take them out after the natural colored silk strands are completely wetted, and control the liquid The rate is 35%, and the colored silk bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com