Low-heat-storage-degree polypropylene composite material for automotive upholstery and preparation method thereof

A technology for automotive interior parts and composite materials, which is applied in the field of low heat storage polypropylene composite materials for automotive interior parts and its preparation, can solve the problems of rising interior temperature and surface temperature, and achieve lower surface temperature, The effect of improving scratch resistance and reducing the ability to absorb light radiant energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

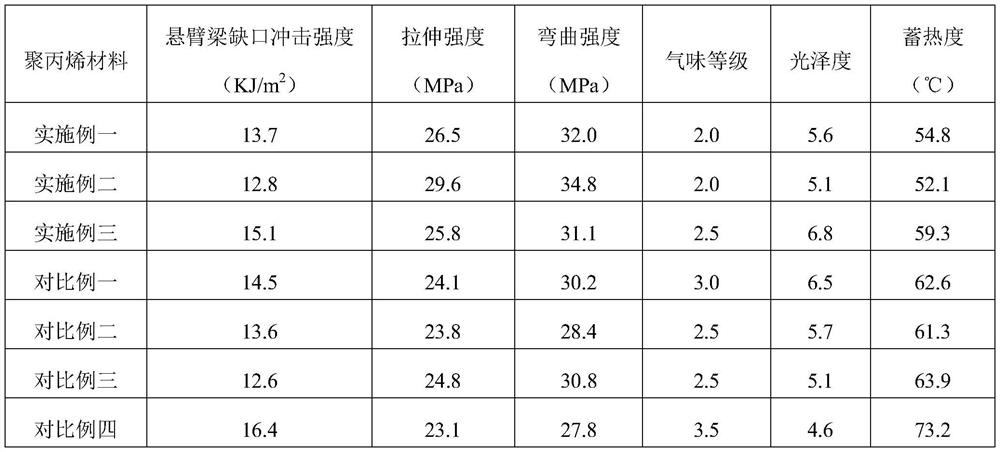

Examples

preparation example Construction

[0034] A preparation method of a low heat storage polypropylene composite material for automotive interior parts of the present invention comprises the following steps:

[0035] 1) Take antioxidant, dispersant, deodorant, anti-scratch agent and stabilizer, mix them evenly, and obtain an auxiliary agent package;

[0036] 2) Take the infrared reflection filler A and the infrared reflection filler B, and mix them evenly to obtain the filler;

[0037] 3) Take polypropylene, polyolefin elastomer and talc, mix, and add the filler obtained in step 2), preliminarily mix, then add the auxiliary agent package and infrared reflective pigment obtained in step 1), blend, mix evenly, double Extruded by screw extruder. The temperature of each zone of the extruder is: 170-185 ℃ for the first stage, 190-210 ℃ for the second stage, 200-210 ℃ for the third stage, 210-215 ℃ for the head, cooling, granulation, and polypropylene composite Material.

Embodiment 1

[0039] A preparation method of a low heat storage polypropylene composite material for automotive interior parts of the present invention comprises the following steps:

[0040] 1) Weigh the raw materials according to the following parts by weight: 65 parts of polypropylene, 10 parts of polyolefin elastomer, 15 parts of talcum powder, 5 parts of infrared reflective filler A, 5 parts of infrared reflective filler B, 0.3 part of antioxidant 1010, antioxidant Agent 168 0.3 part, dispersant EBS 0.5 part, deodorant diatomaceous earth 0.8 part, scratch resistance agent silicone powder 1.5 part, heat stabilizer PS802FL 0.2 part, ultraviolet stabilizer UV-P 0.3 part, light stabilizer 770 0.3 parts, 2 parts of infrared reflective pigment;

[0041] Infrared reflective filler A is ultraviolet and infrared reflective filler, and the ultraviolet and infrared reflective filler is rare earth lanthanum oxide;

[0042] Infrared reflective filler B is visible light and infrared reflective fill...

Embodiment 2

[0048] A preparation method of a low heat storage polypropylene composite material for automotive interior parts of the present invention comprises the following steps:

[0049] 1) Weigh the raw materials according to the following parts by weight: 55 parts of polypropylene, 10 parts of polyolefin elastomer, 15 parts of talc, 10 parts of infrared reflective filler A, 10 parts of infrared reflective filler B, 0.3 part of antioxidant 1010, antioxidant 168 0.3 part, dispersant EBS 0.5 part, deodorant aluminosilicate 0.8 part, scratch resistant silicone powder 1.5 part, heat stabilizer PS802FL 0.2 part, ultraviolet stabilizer UV-P 0.3 part, light stabilizer 770 0.3 parts, 3 parts of infrared reflective pigments;

[0050] The infrared reflective filler A is an ultraviolet and infrared reflective filler, the ultraviolet and infrared reflective filler is rare earth cerium oxide, and the particle size of the infrared reflective filler A is 4-6 μm;

[0051] Infrared reflective filler ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com