Environment-friendly efficient lubricating type ultrathin aluminum foil rolling oil and preparation method thereof

A technology of ultra-thin aluminum foil and rolling oil, which is applied in the field of lubricating oil, can solve the problems of increased metal deformation resistance, high unit pressure, and increased energy consumption, and achieve moderate kinematic viscosity, reduce environmental problems, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of this environment-friendly high-efficiency lubricating ultra-thin aluminum foil rolling oil is as follows:

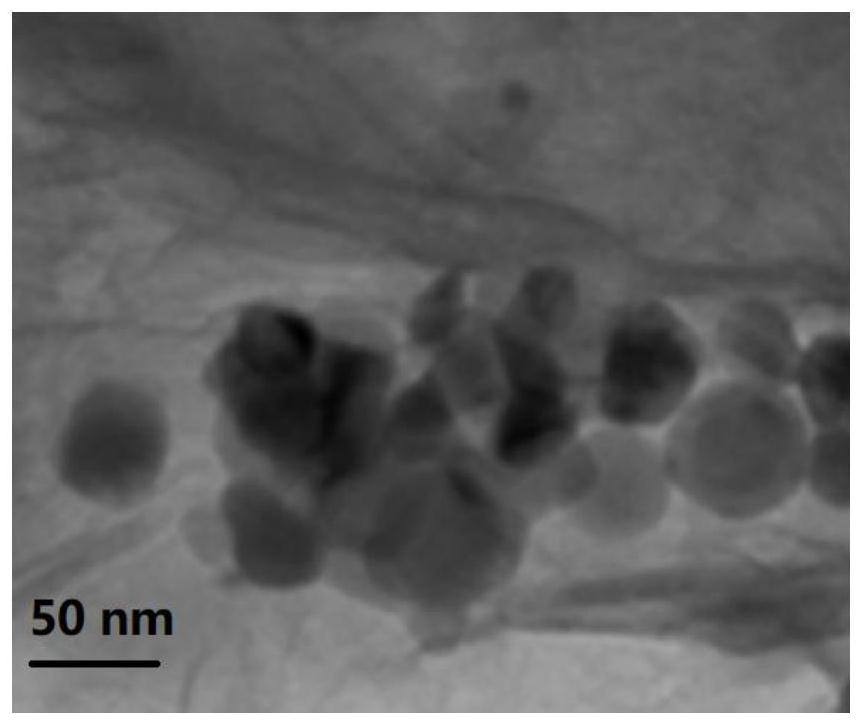

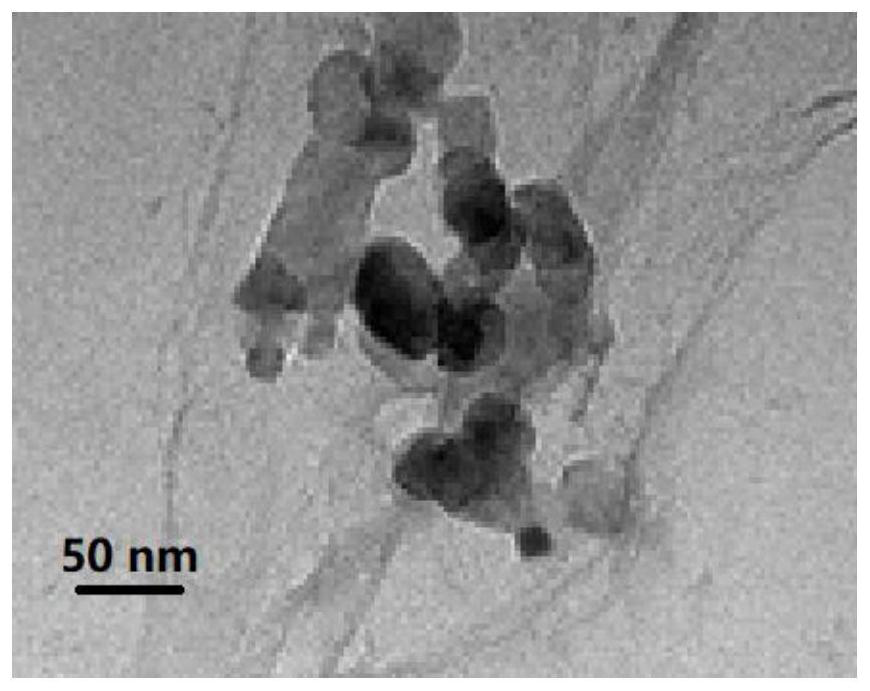

[0039] Step 1. Add 0.1g of graphene oxide-based nano-titanium dioxide, 0.1g of graphene oxide-based nano-zinc oxide, 0.3g of octadecenoic acid and 0.5g of triethanolamine borate into 97.7g of base oil D140 in sequence, and place in the reaction kettle Heat and stir in the medium, the stirring speed is 1000-2500 rpm, when the temperature reaches 60-80°C, keep warm and continue stirring for 20-40 minutes.

[0040] Step 2, then add 0.3 dodecyl alcohol, 0.6g dodecanoic acid, 0.3g isooctyl stearate and 0.1g T508 to the above reaction kettle in turn, continue stirring and heating, the stirring speed is 600-1500 rpm, when the temperature When it reaches 70-80°C, keep warm and keep stirring for 30-60 minutes, then stop heating and continue stirring to room temperature to obtain a uniform transparent oil body, which is formulated as lubricating ultr...

Embodiment 2

[0044] This example provides an environmentally friendly and efficient lubricating ultra-thin aluminum foil rolling oil, which is prepared from the following components and their weight percentages:

[0045] component name Weight percent (100%) Base oil D140 91 Graphene oxide-based nano-titanium dioxide (20-100nm) 0.2 Graphene oxide-based nano zinc oxide (20-100nm) 0.3 octadecenoic acid 0.5 Triethanolamine borate 1.5 Lauryl Alcohol 1.5 Isooctyl stearate 3.0 Dodecanoic acid 1.5 T508 0.5

[0046] The preparation method of this environment-friendly high-efficiency lubricating ultra-thin aluminum foil rolling oil is as follows:

[0047] Step 1. Add 0.2g of graphene oxide-based nano-titanium dioxide, 0.3g of graphene oxide-based nano-zinc oxide, 0.5g of octadecenoic acid and 1.5g of triethanolamine borate into 91g of base oil D140 in turn, and place them in the reaction kettle Carry out heating and stirring, the s...

Embodiment 3

[0050] This example provides an environmentally friendly and efficient lubricating ultra-thin aluminum foil rolling oil, which is prepared from the following components and their weight percentages:

[0051] component name Weight percent (100%) Base oil D140 96.2 Graphene oxide-based nano-titanium dioxide (20-100nm) 0.15 Graphene oxide-based nano zinc oxide (20-100nm) 0.15 octadecenoic acid 0.45 Triethanolamine borate 0.75 Lauryl Alcohol 0.5 Isooctyl stearate 0.5 Dodecanoic acid 1.0 T508 0.3

[0052] The preparation method of this environment-friendly high-efficiency lubricating ultra-thin aluminum foil rolling oil is as follows:

[0053] Step 1. Add 0.15g of graphene oxide-based nano-titanium dioxide, 0.15g of graphene oxide-based nano-zinc oxide, 0.45g of octadecenoic acid and 0.75g of triethanolamine borate into 96.2g of base oil D140 in sequence, and place in the reaction kettle Heat and stir in the mediu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com