A kind of ingot pulling method for smelting ta10 titanium alloy flat ingot in eb furnace

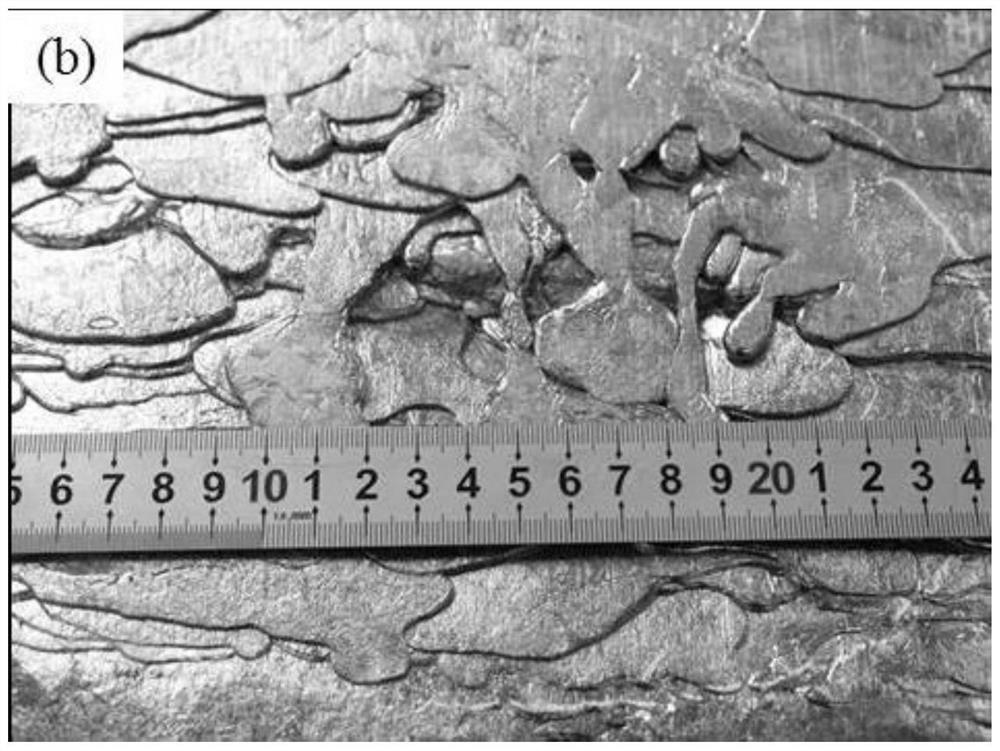

A titanium alloy and flat ingot technology, applied in the field of titanium alloy smelting, can solve the problems of uneven surface of flat ingot, uneven mechanical properties, low material utilization rate, etc. The effect of slow and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of ingot pulling method of smelting TA10 titanium alloy flat ingot in EB furnace, concrete steps are as follows:

[0022] (1) The material of this embodiment is TA10 titanium alloy, the length of the ingot is 7525mm, and the ingot pulling time is 860min.

[0023] (2) Turn on the 4# gun when the titanium liquid flows into the crystallizer, and the power is 50kW.

[0024] (3) Irradiate the 4# gun on the position covered by the titanium liquid in the crystallizer, and start pulling the ingot when the titanium liquid completely covers the crystallizer.

[0025] (4) Increase the power of the 4# gun at the beginning of ingot pulling.

[0026] (5) During the ingot pulling process, the crystallizer water flow rate is 2000L / min, the inlet water temperature is 24-25°C, the outlet water temperature is 25-28°C, and the temperature difference is 0.5-4°C.

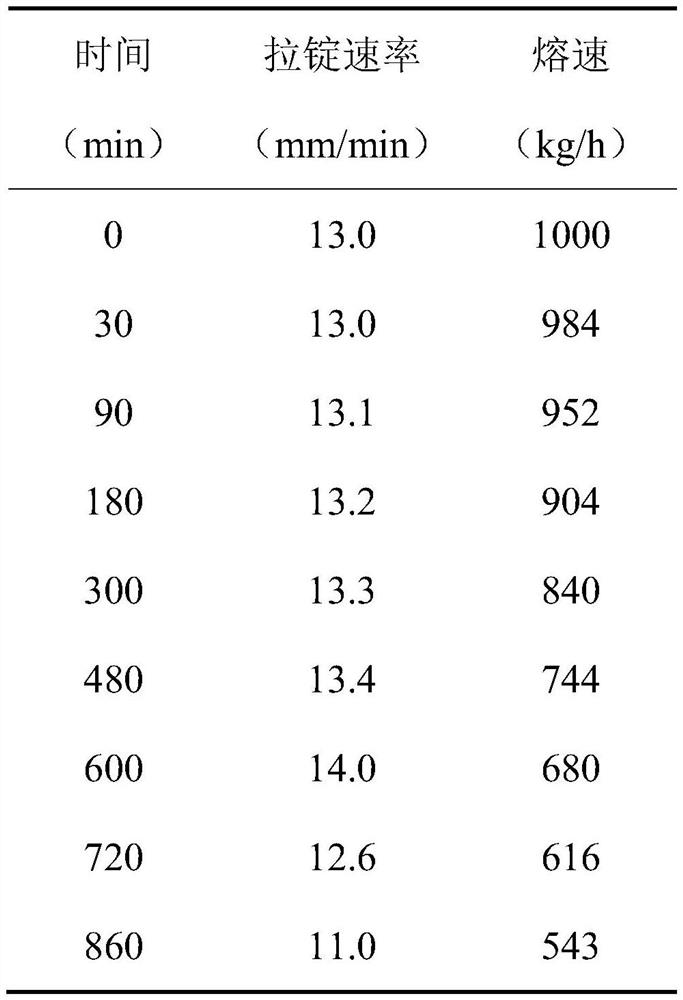

[0027] In this embodiment, when the ingot pulling time t is between 0-8h and the ingot pulling speed v satisfies the fo...

Embodiment 2

[0032] A kind of ingot pulling method of smelting TA10 titanium alloy flat ingot in EB furnace, concrete steps are as follows:

[0033] (1) The material of this embodiment is TA10 titanium alloy, the length of the ingot is 7876mm, and the ingot pulling time is 830min.

[0034] (2) Turn on the 4# gun when the titanium liquid flows into the crystallizer, and the power is 50kW.

[0035] (3) Irradiate the 4# gun on the position covered by the titanium liquid in the crystallizer, and start pulling the ingot when the titanium liquid completely covers the crystallizer.

[0036] (4) Increase the power of the 4# gun at the beginning of ingot pulling.

[0037] (5) During the ingot pulling process, the crystallizer water flow rate is 1800L / min, the inlet water temperature is 21-25°C, the outlet water temperature is 22-28°C, and the temperature difference is 1-4°C.

[0038] In the present embodiment, when the ingot pulling time t is between 0-8h and the ingot pulling speed v satisfies t...

Embodiment 3

[0044] A kind of ingot pulling method of smelting TA10 titanium alloy flat ingot in EB furnace, concrete steps are as follows:

[0045] (1) The material of this embodiment is TA10 titanium alloy, the length of the ingot is 7836mm, and the ingot pulling time is 780min.

[0046] (2) Turn on the 4# gun when the titanium liquid flows into the crystallizer, and the power is 50kW.

[0047] (3) Irradiate the 4# gun on the position covered by the titanium liquid in the crystallizer, and start pulling the ingot when the titanium liquid completely covers the crystallizer.

[0048] (4) Increase the power of the 4# gun at the beginning of ingot pulling.

[0049] (5) During the ingot pulling process, the crystallizer water flow rate is 2000L / min, the inlet water temperature is 21-25°C, the outlet water temperature is 23-28°C, and the temperature difference is 1.5-4°C.

[0050] In this embodiment, the ingot pulling time t is between 0-8h and the ingot pulling speed v satisfies the formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com