Manufacturing method of blackening-free aluminized paper after labeling for beer bottles

A production method and labeling technology, applied in the field of labeling and packaging, can solve the problems of mold, cost, and failure to meet user satisfaction and environmental protection requirements, and achieve the effect of inhibiting blackening and improving market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

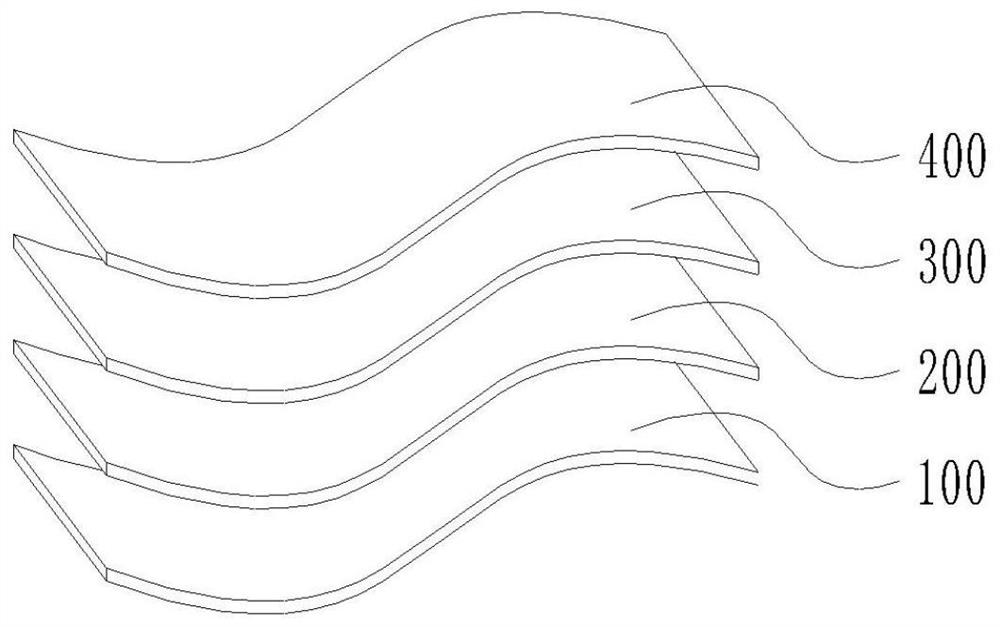

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0019] Research on the glue for labeling found that the PH value is alkaline, and the blackening is due to the fact that the labeling glue penetrates into the aluminum layer and reacts with the aluminum, and the ink on the label looks black.

[0020] In fact, the pure reactant is not black. Aluminum is difficult to react with water at room temperature, but in a large amount of OH - In the presence of Al(OH), the reducibility is enhanced, and it is easier to react with water to form Al(OH) 3 ,

[0021] Aluminum is difficult to react with water at room temperature, but in a large amount of OH - In the presence of Al(OH), the reducibility is enhanced, and it is easier to react with water to form Al(OH) 3 , amphoteric Al(OH) 3 Then react with NaOH to generate sodium metaaluminate and water.

[0022] When the aluminum layer is in contact with this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com