Intelligent control method for ballastless track steel rail laying process

A technology of ballastless track and intelligent control, which is applied in the direction of track, track maintenance, track laying, etc. It can solve problems such as track laying deviation, and achieve the effect of increasing operating speed, improving efficiency, and better riding experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

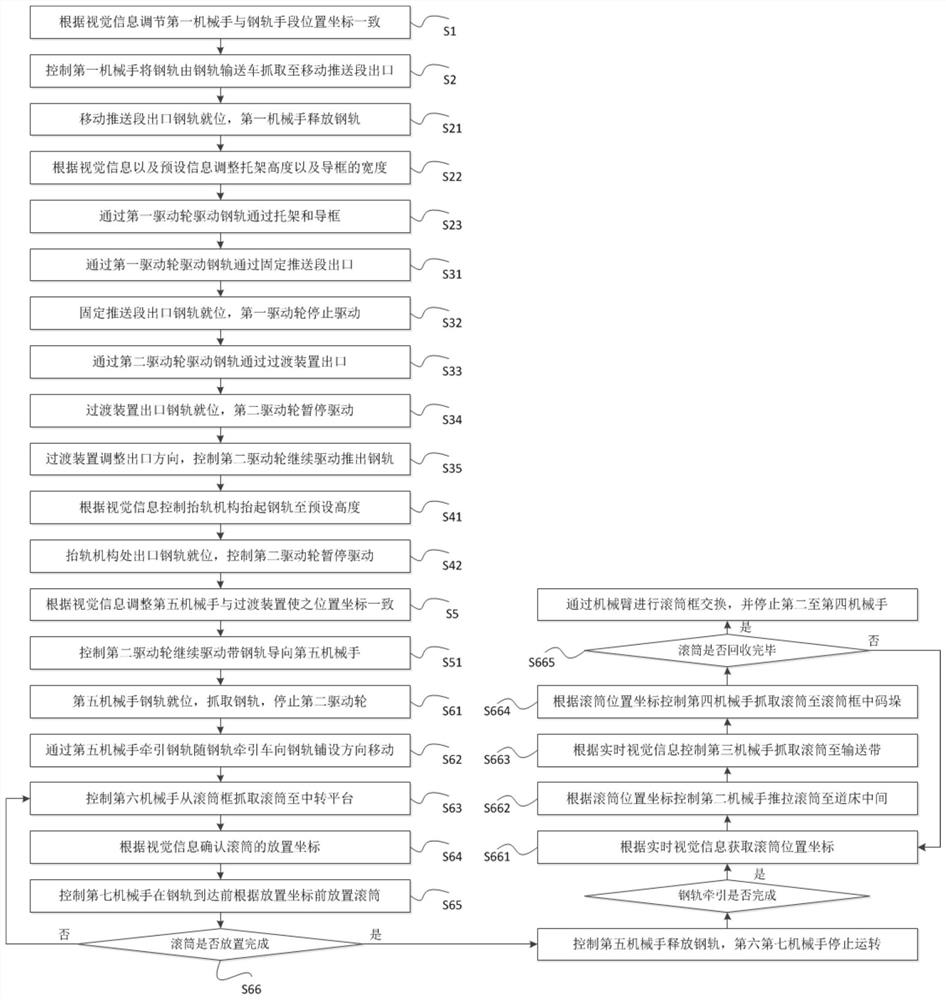

Image

Examples

Embodiment Construction

[0049] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0050] In the process of sequentially transporting the rails from the rail conveying vehicle to the rail pushing vehicle, the roller recovery vehicle and the rail tractor, there are multiple transfers of different traction devices. During these transfers, the rail clamps are often fixed, and the rail clamps The position may be shifted due to the position deviation of the construction vehicle itself. At the same time, the manual operation of grabbing rails, aligning rails and recycling rollers has a greater safety risk. In order to solve the above problems, such as figure 1As shown, the present invention proposes an intelligent control method for the laying process of ballastless track rails. The main control system controls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com