Rapid construction method for filling filter material in constructed wetland unit pool

A technology of artificial wetlands and construction methods, which is applied in the direction of filling, artificial waterways, chemical instruments and methods, etc., and can solve problems such as uneven thickness of layered filling, irregular dividing line of segmented filling, confusion of filter materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

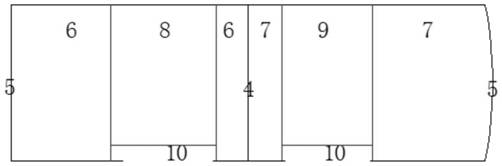

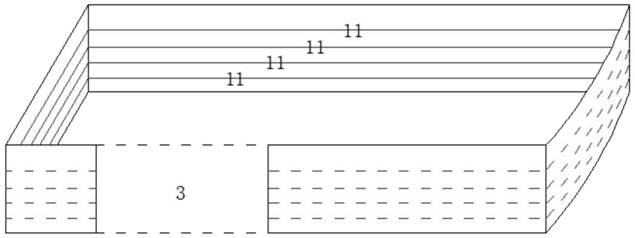

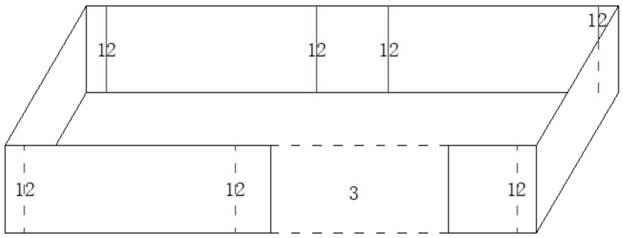

[0048] Such as figure 1The construction plan of filter material filling in the constructed wetland unit pool is shown, the constructed wetland unit pool includes an upflow pool 1 and a horizontal flow pool 2, the horizontal flow pool 2 is a cuboid structure, and the upflow pool 1 is irregular The middle is separated by the unit flower wall 4, and two 10m-long reserved openings 3 are set on the unit side wall 5 along the 5m positions on both sides of the unit flower wall 4.

[0049] Such as figure 2 As shown, the filter material filling area is divided into: the first filling area 6, the second filling area 7, the third filling area 8, the fourth filling area 9 and the remaining filter material filling area 10, a total of 5 Packing area where:

[0050] The first filling area 6 is the filter material filling area on both sides of the reserved opening of the upflow pool 1;

[0051] The second filling area 7 is the filter material filling area on both sides of the reserved ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com