Anti-corrosion coating device for inner pipe wall of metal pipeline

A technology for metal pipelines and coating devices, which is applied to devices for coating liquids on surfaces, coatings, pretreatment surfaces, etc., can solve certain difficulties in pipeline anticorrosion, the spray coating effect of the pipe wall needs to be improved, the pipeline is long and narrow, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

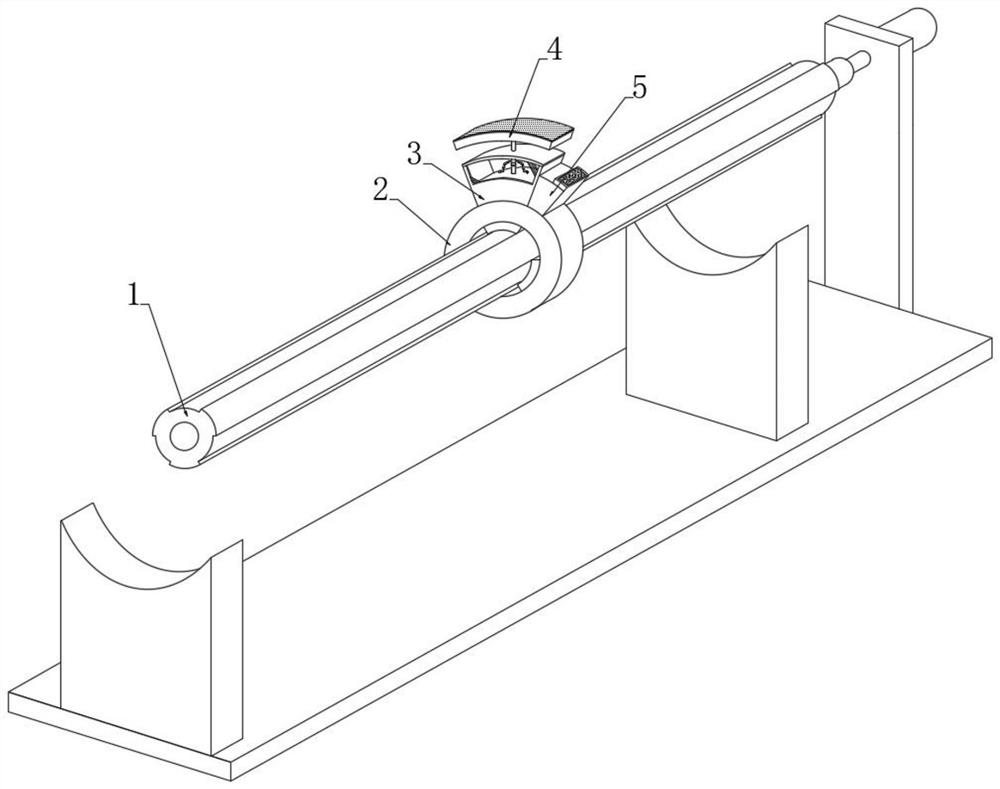

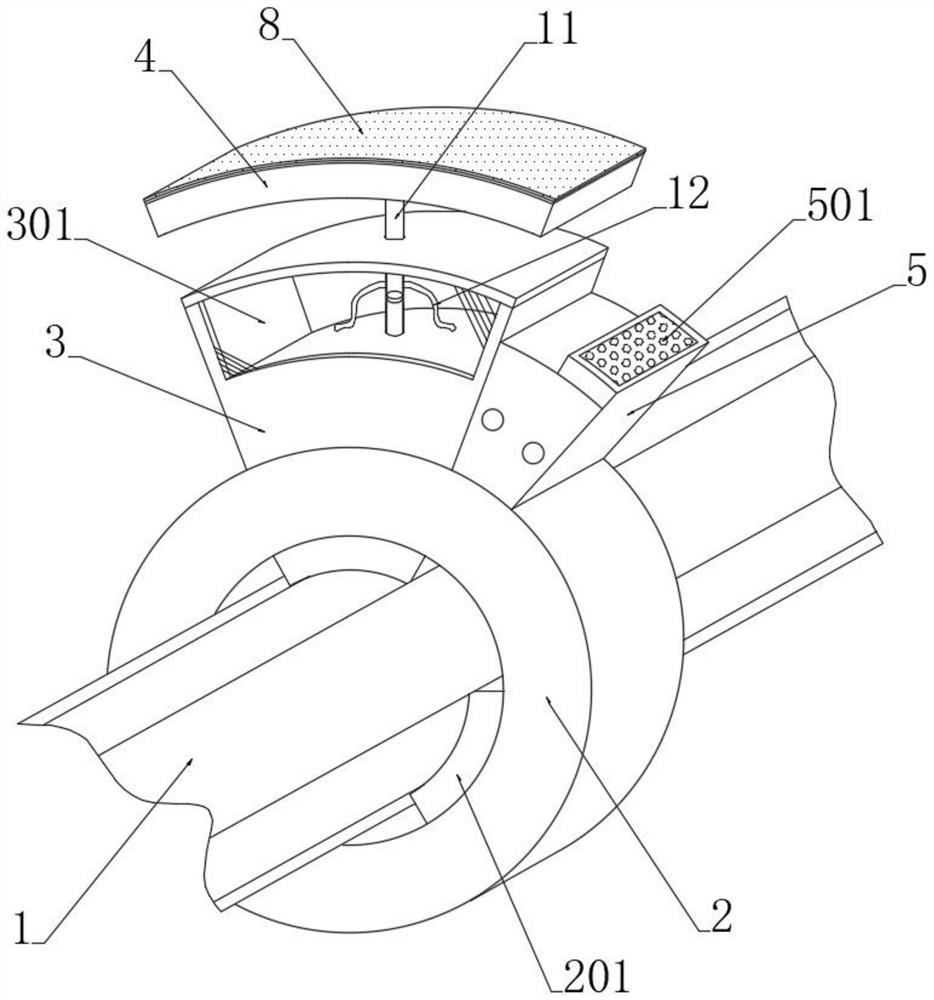

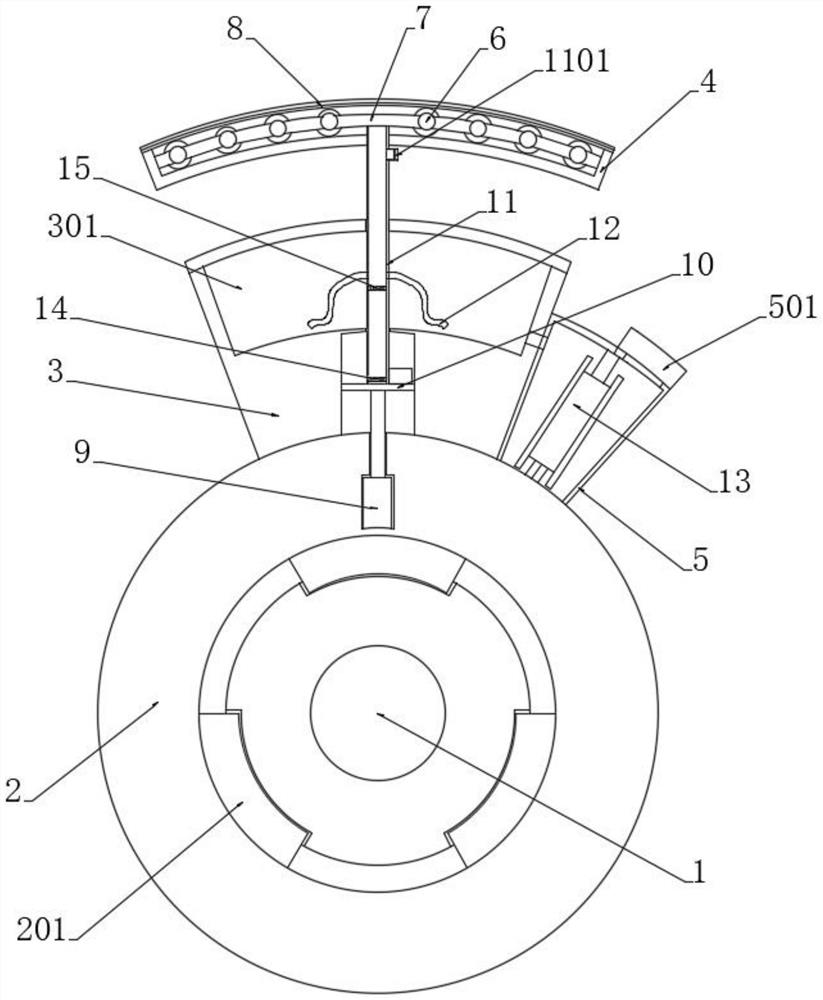

[0037] see Figure 1-3 , an anti-corrosion coating device for the inner pipe wall of a metal pipeline, comprising a sliding column 1 rotatably mounted on a support frame, a motor for rotating the sliding column 1 is installed on the support frame, and the sliding column 1 is slidably connected with a An annular sliding seat 2, the inner wall of the annular sliding seat 2 is provided with a plurality of electric sliders 201 that are slidably connected to the outer wall of the sliding column 1, and the outer wall of the sliding column 1 is provided with a plurality of sliding blocks that match the electric sliders 201. The cavity is convenient to realize that the annular sliding seat 2 can not only translate in the horizontal direction but also rotate in the circumferential direction.

[0038] The top side wall of the annular sliding seat 2 is fixedly connected with a fan-shaped material storage box 3, and the top of the fan-shaped material storage box 3 can be lifted and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com