Method and device for grabbing various types of circuit boards

A circuit board, type of technology, applied in printed circuits, transportation and packaging, printed circuit manufacturing, etc., can solve problems such as increasing the cost of robots, and achieve the effect of reducing investment and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

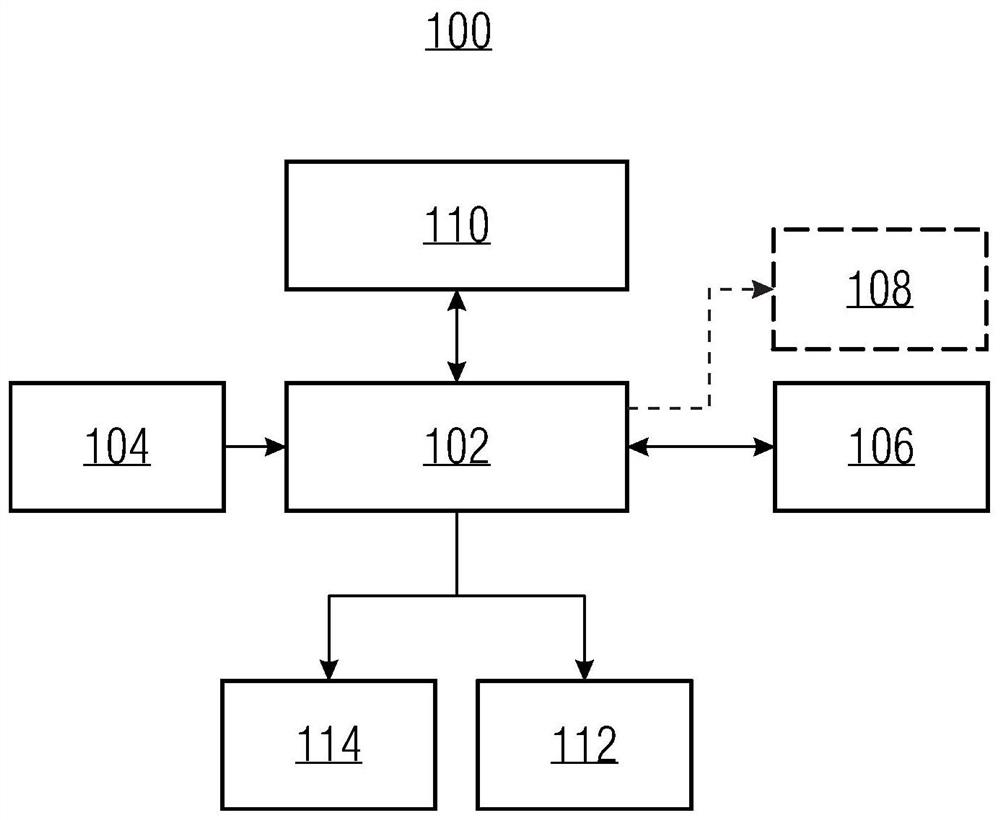

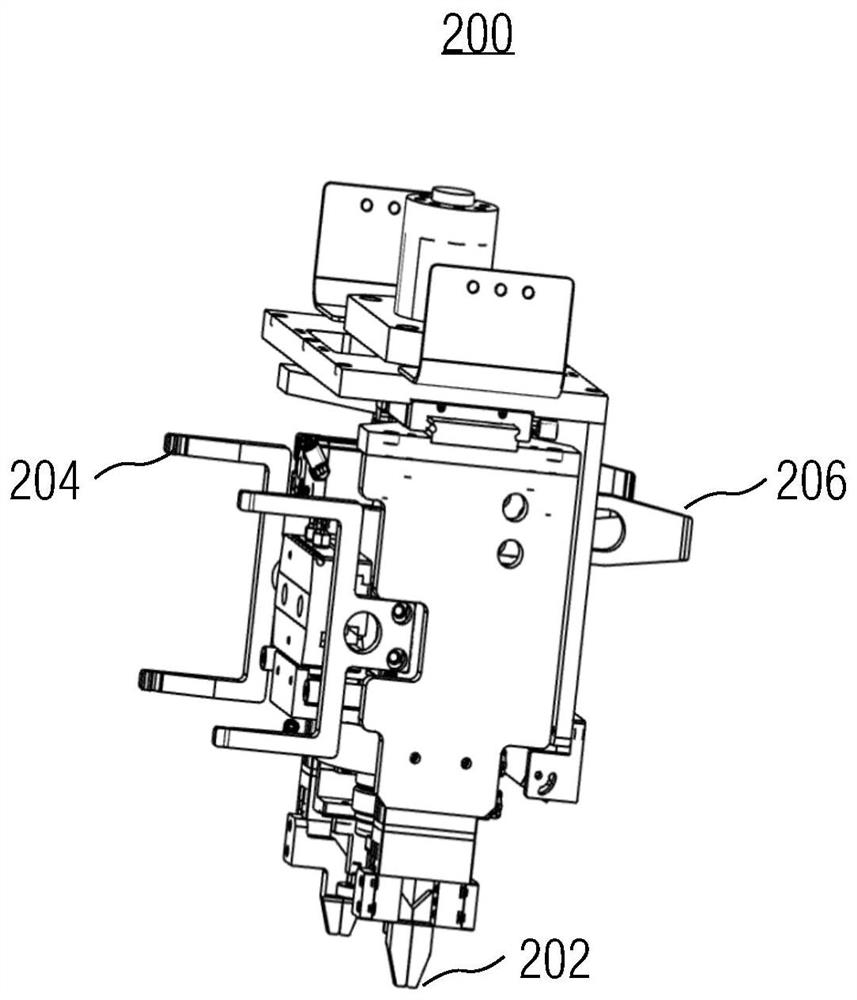

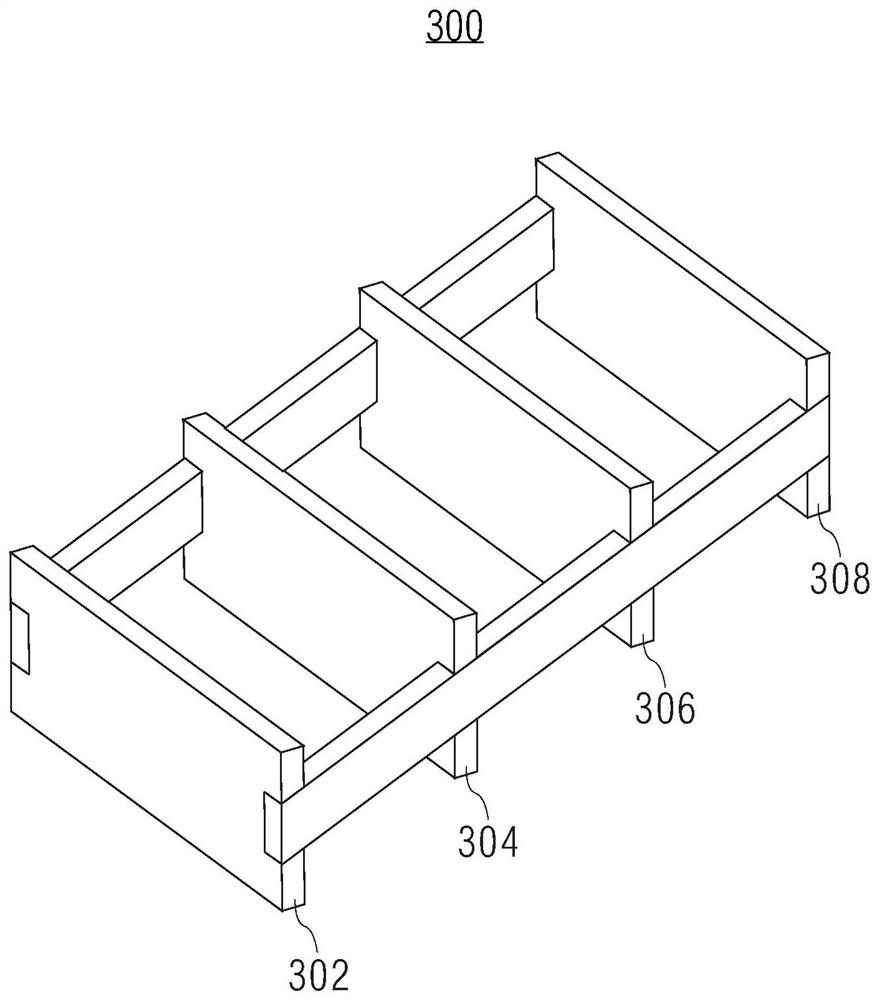

[0072] Printed circuit board (PCB) is one of the important components of the electronics industry and is the carrier of the electrical connection of electronic components. In the PCB assembly process, it is usually necessary to divide the entire circuit board to obtain a single circuit board. The invention proposes the technology of using an integrated mechanical gripper to grasp and load and unload a plurality of different types of circuit boards during the process of separating the PCBs.

[0073] The present disclosure will now be discussed with reference to various exemplary embodiments. It should be understood that the discussion of these embodiments is only for the purpose of enabling those skilled in the art to better understand and thus implement the embodiments of the present disclosure, rather than teaching any limitation to the scope of the present disclosure.

[0074] Various embodiments of the present invention will be described in detail below with reference to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com