An industrial sewage treatment device that can automatically clean based on 5g technology

A technology for sewage treatment and automatic cleaning, which is applied in sterilization/microdynamic water/sewage treatment, energy waste water treatment, water/sewage treatment, etc. It can solve the problems of difficult cleaning and multiple impurities, and achieve the effect of saving water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

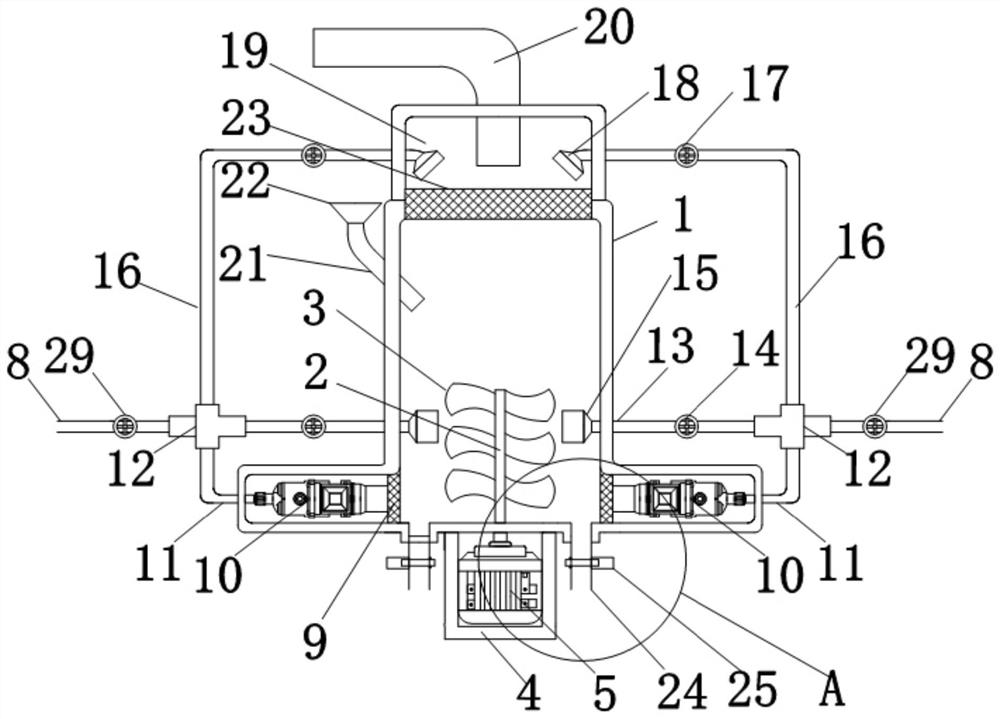

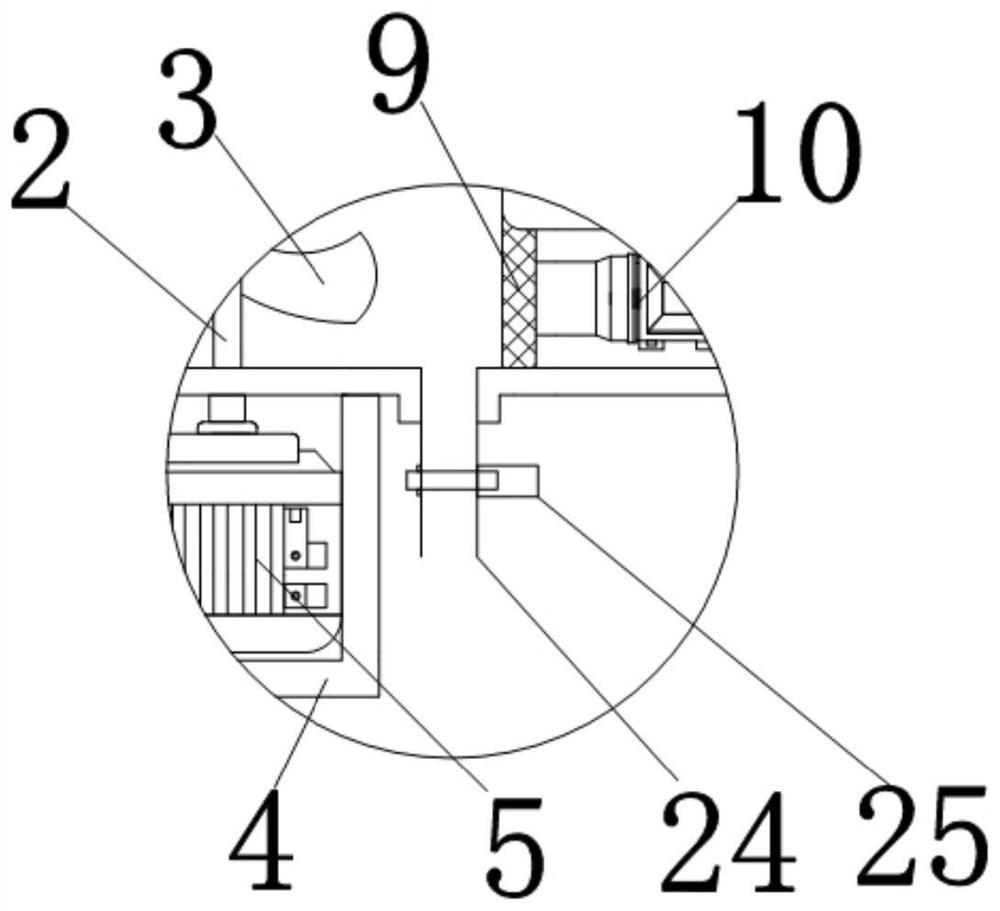

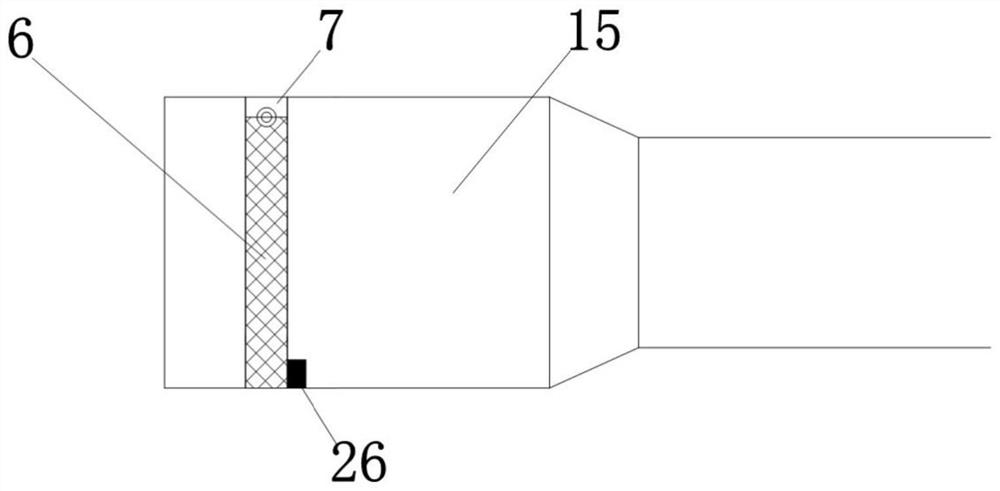

[0027] see Figure 1-4, In the embodiment of the present invention, an industrial sewage treatment device that can be automatically cleaned based on 5G technology includes a sewage treatment tank 1 and a filter box 19. The upper end of the sewage treatment tank 1 is provided with a filter box 19. The filter box 19 and the sewage treatment tank A filter screen 23 is arranged between 1. Before the sewage is treated with medicine, the sewage is filtered for the first time, and the larger substances are left in the filter box 19. The upper end of the filter box 19 is inserted with a sewage discharge pipe 20. It is convenient to discharge the sewage into the filter box 19. The sewage treatment tank 1 is provided with a suction pump 10 on both sides of the lower end. The suction pump 10 is electrically connected to the controller, the controller is connected to the 5G module, and the controller remotely controls the suction pump through the 5G module. 10 Start to work, the sewage in...

Embodiment 2

[0037] In the process of implementing the present invention and putting it into the test, the inventor found that when there are many sludge, particulate impurities, etc. in the sewage, flocculants, disinfectants, etc. are added into the sewage treatment tank 1 through the funnel 22 and the drug injection pipe 21 to make the sewage. After flocculation and sedimentation of sludge and particulate impurities to the bottom of sewage treatment tank 1, due to the effect of the flocculant due to the greater adhesion and pelleting, if the flocculation and sedimentation of sludge and impurities at the bottom of sewage treatment tank 1 are not removed in time , Due to the flocculation and pelletizing effect of the flocculant, the precipitated sludge and impurities are further flocculated and pelletized by the flocculant, and the larger impurity flocculation group will stick and squeeze the stirring blade 3, commonly known as "pressure rake". ”, causing the stirring blade 3 to fail to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com