A portable electrospinning device

An electrospinning and equipment technology, applied in the field of portable electrospinning equipment, can solve problems such as inconvenient operation, and achieve the effects of easy portability, high push rod strength, and stable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

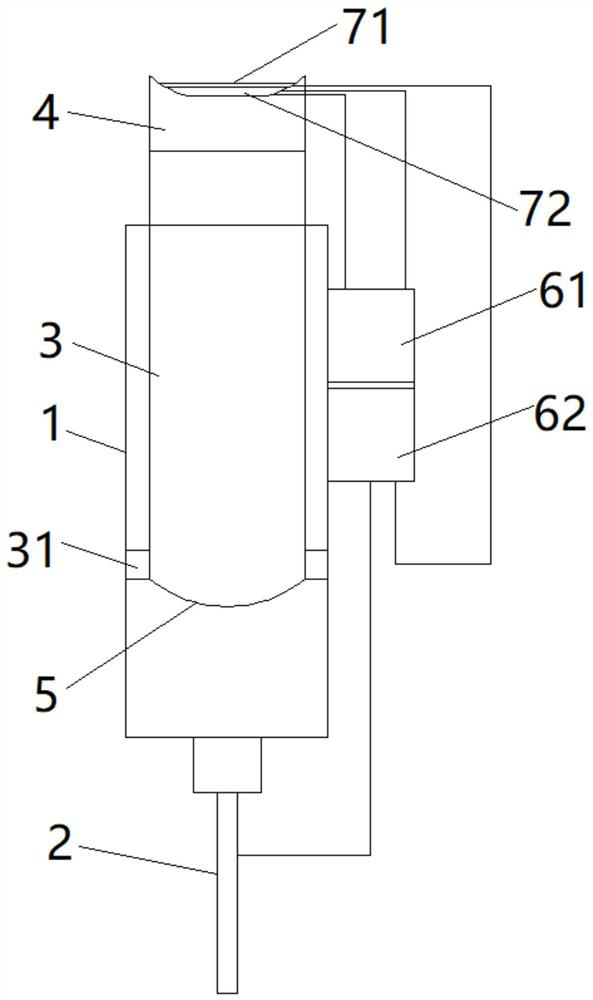

[0041] This embodiment provides an electrospinning device, such as figure 1 As shown, it includes an injection cylinder 1 , a push rod 3 , a blocking component 4 and a one-way throttling component 5 .

[0042]Wherein, the end of the injection cylinder 1 close to the needle 2 is the first front end, and the stainless steel needle 2 is installed on the opening of the first front end of the injection cylinder 1 . The push rod 3 is a hollow structure, which has a hollow cavity. The hollow cavity is arranged axially through the push rod 3. The end of the push rod 3 close to the needle 2 is the second front end, and the end facing away from the needle 2 is the second rear end. The hollow cavity is in the Two ends of the push rod 3 respectively form a second front opening and a second rear opening.

[0043] The injection cylinder 1 and the push rod 3 are both hollow cylinders. The outer diameter of the push rod 3 is larger than the radius of the injection body. When the operator pre...

Embodiment 2

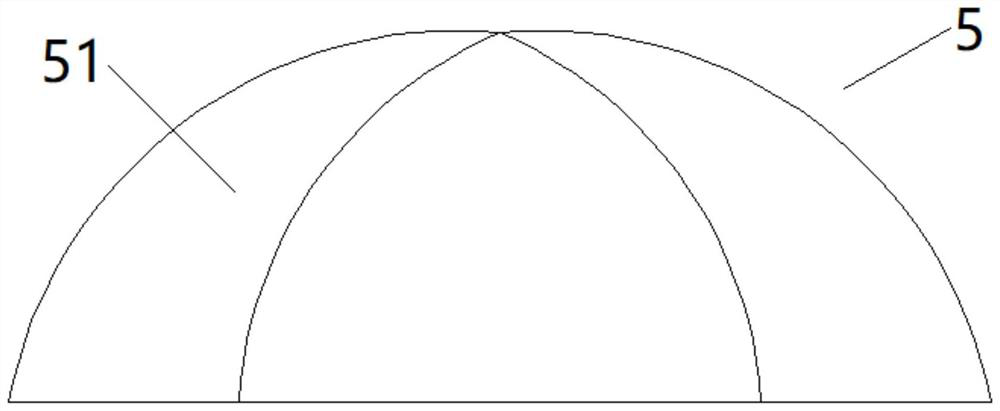

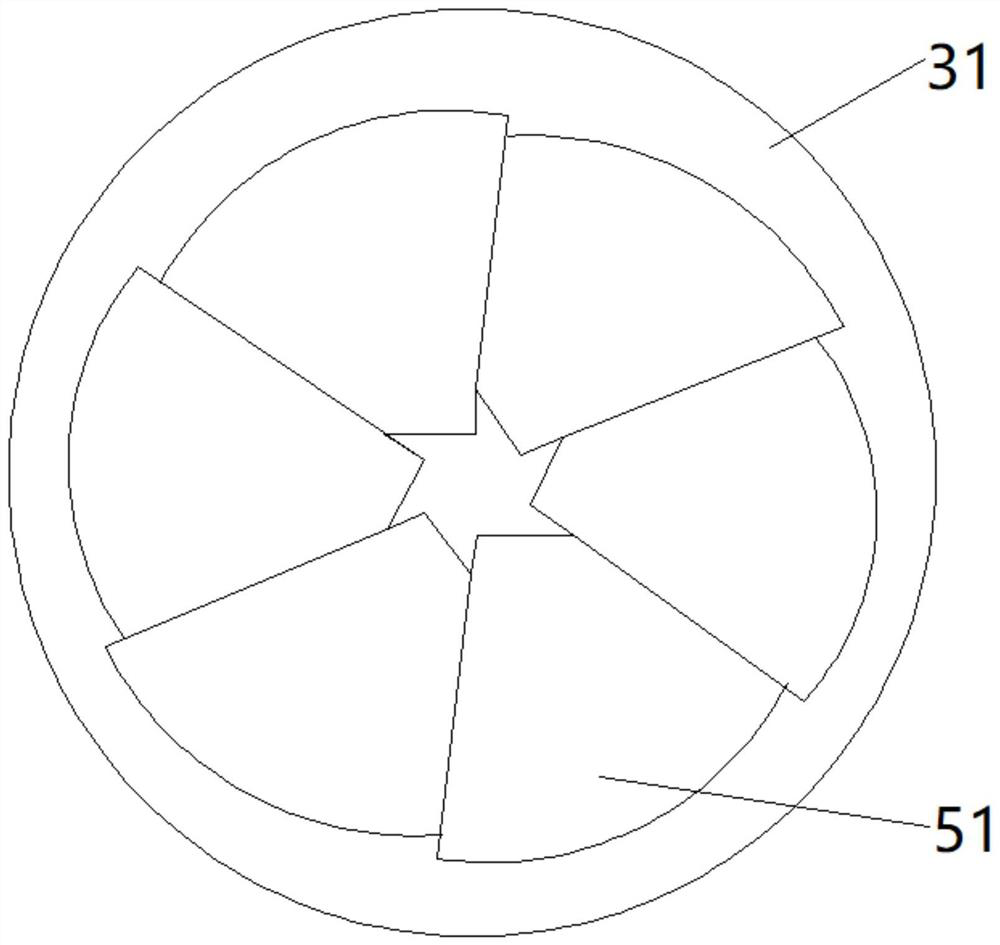

[0054] This embodiment provides an electrospinning device, see figure 2 and image 3 , it differs from Embodiment 1 in that the one-way throttling member 5 includes a plurality of baffles 51, the baffles 51 are in the shape of fan-shaped petals, any baffle 51 has a fixed end and a free end, and the baffles are rigid materials Made, the fixed end of the catch is hinged on the end surface of the annular boss 31, the free end of the catch is inclined inward toward the center line of the push rod 3, and the adjacent ends of any two adjacent catches 51 are pressed against each other. Together, the plurality of blocking pieces 51 are pressed together to form a closed bud shape, and a second cavity protruding toward the needle 2 is formed at the second front end of the push rod 3 .

[0055] When in use, the spinning solution is located in the first cavity, pushes the push rod 3, the free ends of the plurality of baffles 51 gather at the centerline of the push rod 3, the second cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com