Cellulose fiber containing fabric

A cellulose fiber and cellulose technology, applied in fiber treatment, cellulose/protein conjugated artificial filament, fiber chemical characteristics, etc., can solve problems such as low degree of bonding, fading of fabrics, and incomplete penetration of dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

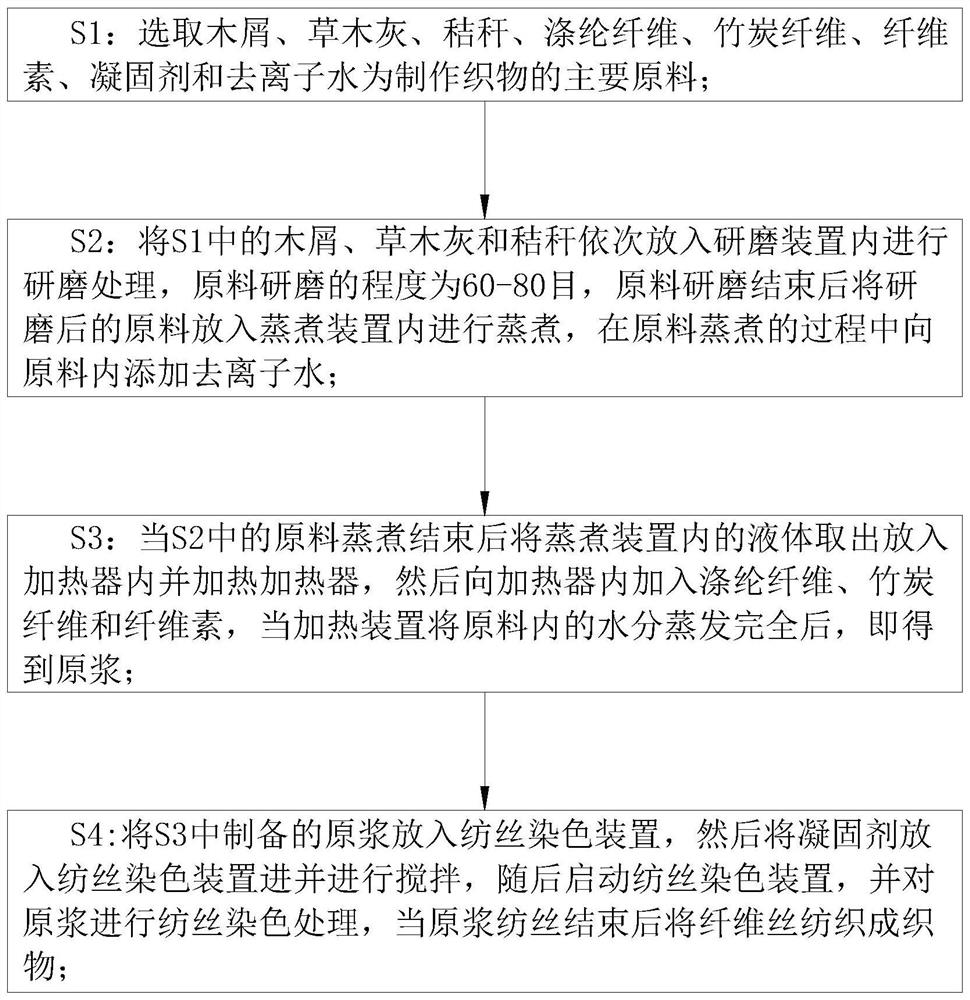

Method used

Image

Examples

Embodiment approach

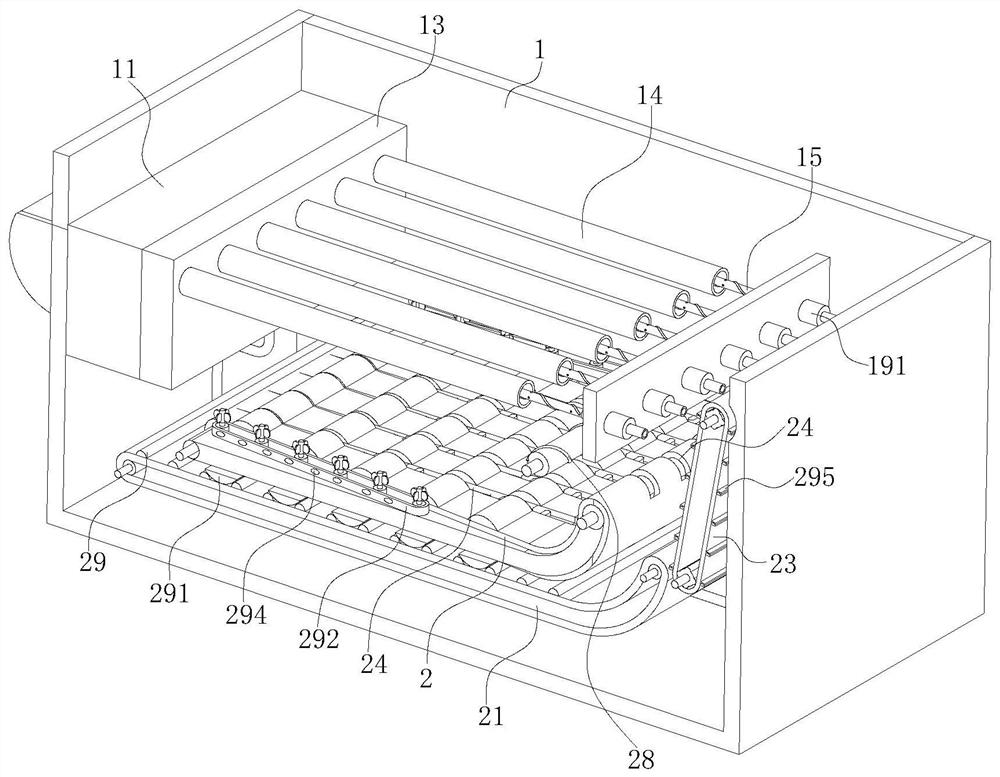

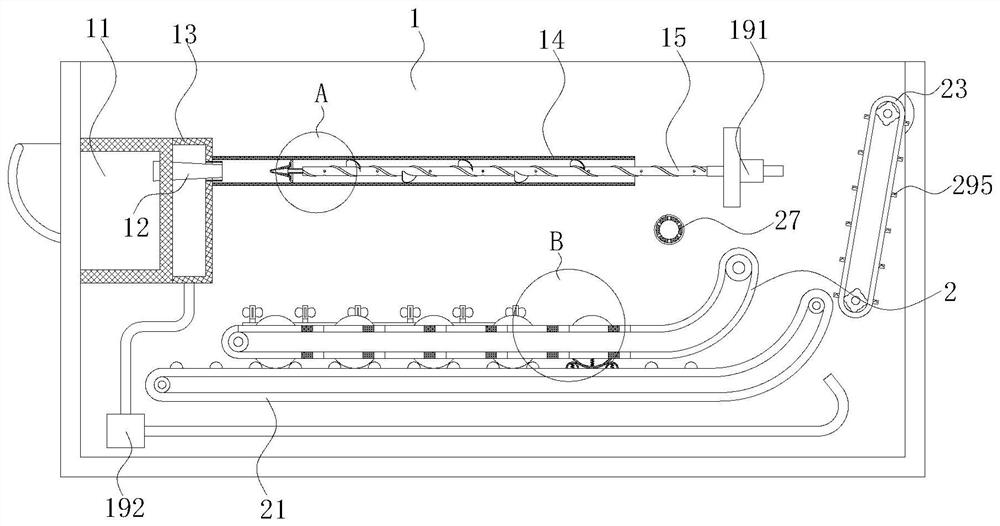

[0058] As an embodiment of the present invention, the outer surface of the second conveyor belt 21 is fixed with uniformly arranged first spacers 29, and the first spacers 29 are made of sponge material; the second conveyor belt 21 The outer surface is fixed with evenly arranged second spacers 291, and the second spacers 291 are placed on both sides of the uniformly arranged annular groove 24; each of the second spacers 291 corresponds to the first spacer 29 , and the second spacer 291 is made of sponge material;

[0059] During work, because the first spacer 29 and the second spacer 291 are made of uniform sponge material, when the fiber filament was placed between the first conveyor belt 2 and the second conveyor belt 21, the first spacer 29 and the second spacer Bar 291 can be extruded, and in this process, the moisture in the first spacer bar 29 and the second spacer bar 291 can be squeezed out, and the remaining dyestuff is adhered in the fiber filament, and simultaneousl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com