Melt-blown cloth production line and production line equipment

A melt-blown cloth and production line technology, applied in the field of non-woven fabrics, can solve problems such as low strength, difficulty in microbial degradation, and limit the use range of melt-blown ultra-fine fibers, and achieve the effect of enhancing the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

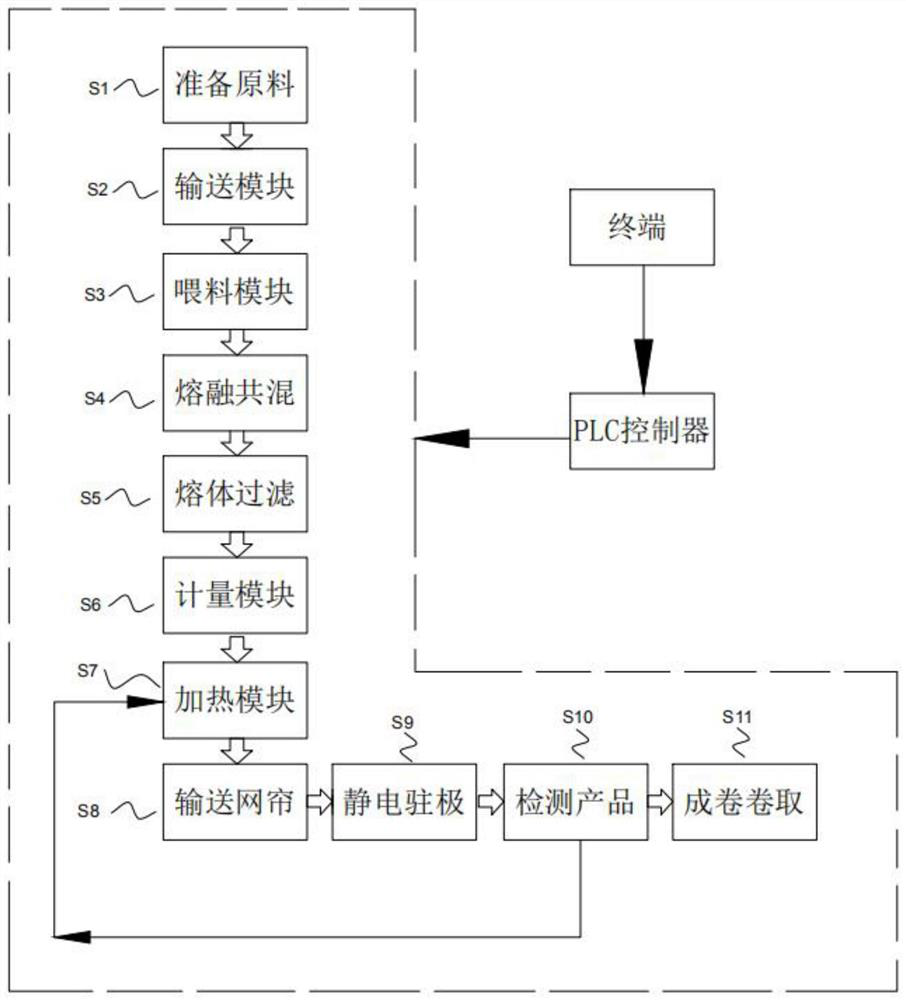

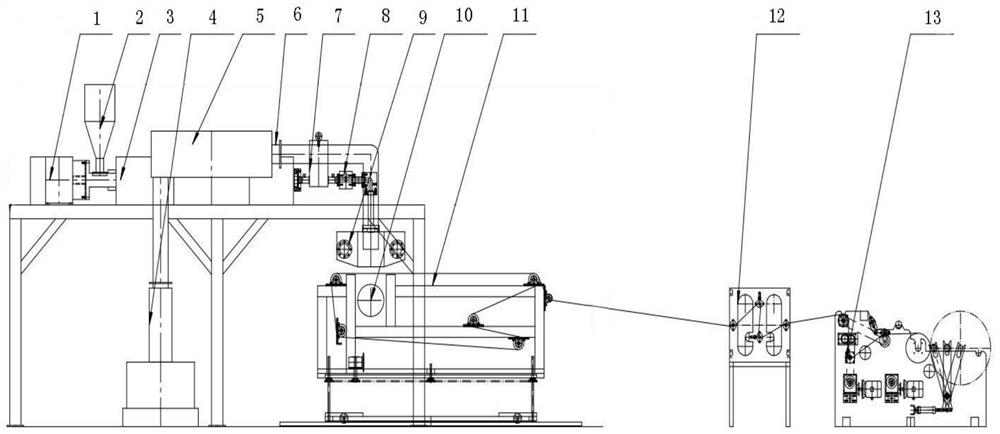

[0050] A production line for melt-blown cloth, comprising the following steps:

[0051] S1, prepare raw materials, high-purity polypropylene, modification additives;

[0052] S2, the conveying module, conveys the polypropylene with a certain purity to the hopper 2 through the conveyor belt, and the conveyer belt is equipped with a deceleration motor 1 for conveying control, and the motor is a frequency conversion deceleration motor;

[0053] S3, the feeding module, consists of 1-3 measuring hoppers, which are used to measure white slices, masterbatches and additives respectively, and put the inorganic fungicide and other 3 components into the mixing mixer to mix evenly;

[0054] S4, send the mixed and stirred raw materials into the extruder for melting and blending, and then send the chips into the twin-screw extruder 3 for melting, the screw diameter is 60-120mm, the length / diameter ratio is 30, and the melting temperature is 200°C -300°C;

[0055] S5, the melt filtration m...

Embodiment 2

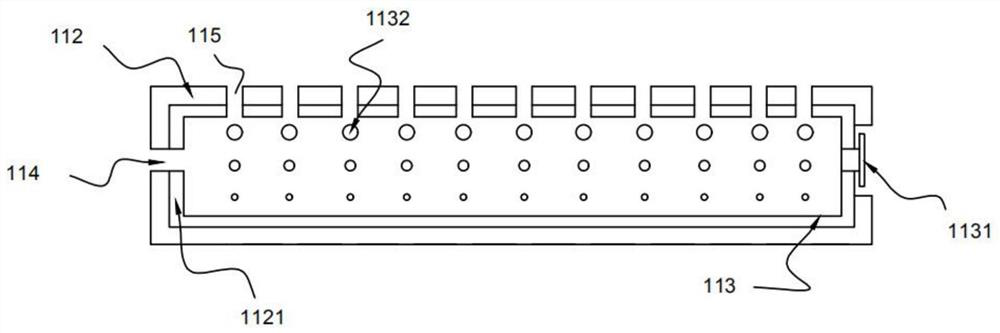

[0065] A production line for meltblown cloth, the melting temperature in step S4 is provided with nine temperature control zones, the temperature control zones are respectively 140°C in the first zone, 165°C in the second zone, 185°C in the third zone, 200°C in the fourth zone, and 200°C in the fifth zone. Zone 225°C, Zone 6 245°C, Zone 7 265°C, Zone 8 285°C, Zone 9 300°C, the nine temperature control zones can be controlled in any segment according to the situation, and the temperature control time of the temperature control zone Segmented control, the time of the segmented control is 20 minutes for zone 1, 10 minutes and 15 minutes for zone 2 to zone 3, 10 minutes for zone 4 to zone 6, 15 minutes for zone 7 to zone 8, and 15 minutes for zone 9 to zone 9. 30 minutes. In order to accelerate the adhesion and cooling effect, an external cooling process will be carried out. The air inlet on the roll is connected to the air-conditioning box to introduce cold air, and then leads to...

Embodiment 3

[0067] A production line for meltblown cloth, the melting temperature in step S4 is provided with five temperature control zones, the temperature control zones are respectively 135°-165°C in the first zone, 165°-200°C in the second zone, and 200°-200° in the third zone. 245°C, 245°-285°C in the fourth zone, and 285°-300°C in the fifth zone. The temperature control time of the temperature control zone is controlled in sections. Time control for 15 minutes, 10 minutes for the third to fourth zones, and 30 minutes for the fifth zone. In order to accelerate the adhesion and cooling effect, an external cooling treatment will be carried out. The air inlet on the roll is connected to the air-conditioning box to introduce cold air, and then leads to the air hole through the internal pipe. The aperture of the air hole can be adjusted by external rotation. The delivery temperature was 18°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com