Underground gas-driven drainage pump and gas-driven drainage method

A technology of gas drive and pump barrel, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of limited application range, eccentric wear of pipes and rods, and large versatility limitations, and achieve easy ground automation Control and management, energy saving and work efficiency are obvious, and the effect of high work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

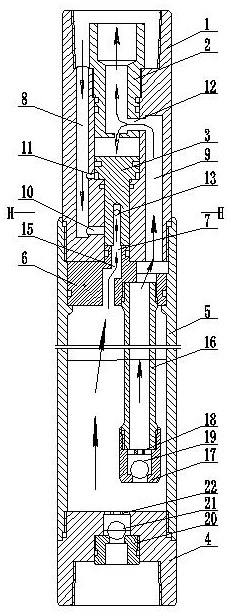

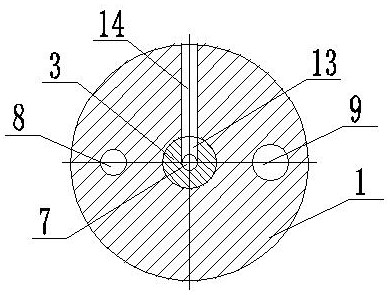

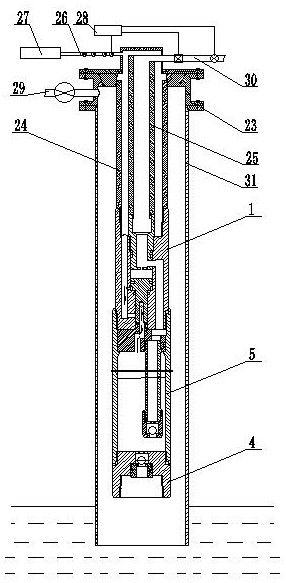

[0038] The downhole gas drive drainage pump includes a drainage pump casing 1, a pump barrel 5, an inner joint 2, a valve core 3, a lower joint 4 and a diverter block 6; A diverter block 6 is installed through the inner flange, and a drainage pump housing 1 is mounted on the top thread of the pump cylinder 5, and the drainage pump housing 1 cooperates with the inner flange to form an axial limit for the diverter block 6.

[0039] The drainage pump housing 1 is provided with a stepped center hole, the inner thread of the upper port of the center hole is equipped with an inner joint 2, the inner joint 2 is a barrel-shaped body, and the center of the inner joint 2 is provided with a stepped central hole. The bottom of the central hole of the inner joint 2 is constricted, which is used to transmit pressure to the bottom.

[0040]A spool 3 is installed in the center hole below the inner joint 2. The spool 3 is a T-shaped variable diameter body. The center of the lower end of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com