Lithium battery thermal runaway detection system and method

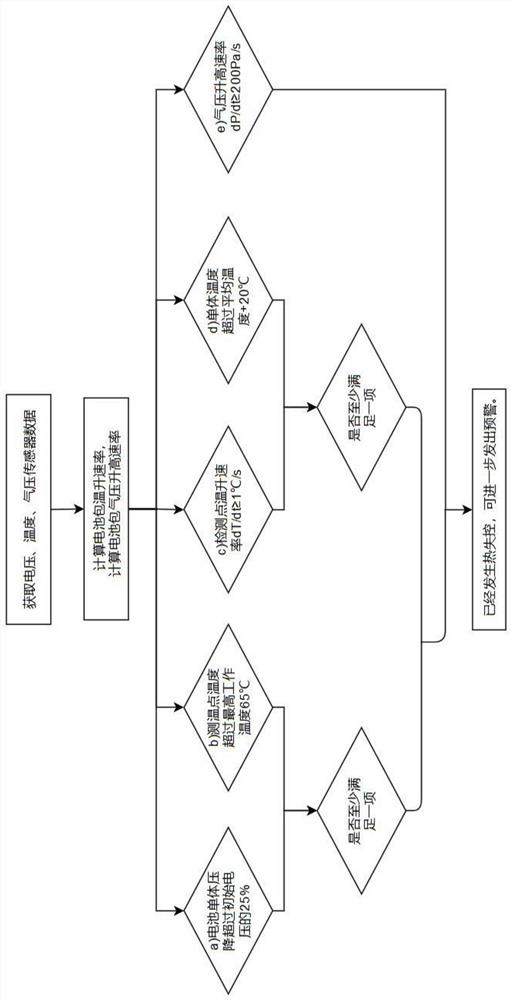

A detection method and technology of a detection system, applied in the field of detection systems, can solve problems such as inability to output valid data, low precision, failure of BMS system, etc., achieve good promotion prospects and application value, improve accuracy and reliability, and detect reliably sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The lithium battery thermal runaway detection system and method of the present invention will be further explained and illustrated in conjunction with the accompanying drawings and specific examples below. However, such explanations and illustrations do not constitute undue limitations on the technical solution of the present invention.

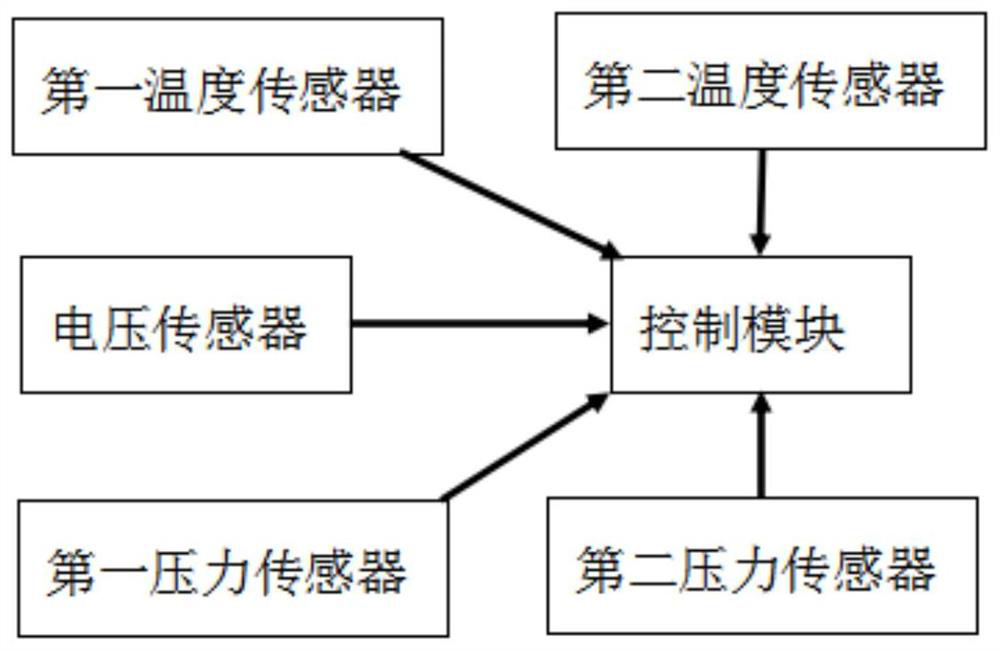

[0046] figure 1 It is a structural block diagram of a lithium battery thermal runaway detection system in an embodiment of the present invention.

[0047] Such as figure 1 As shown, in this embodiment, the lithium battery thermal runaway detection system of the present invention includes: a first temperature sensor, a voltage sensor, a first pressure sensor, a second pressure sensor, a control module and a second temperature sensor.

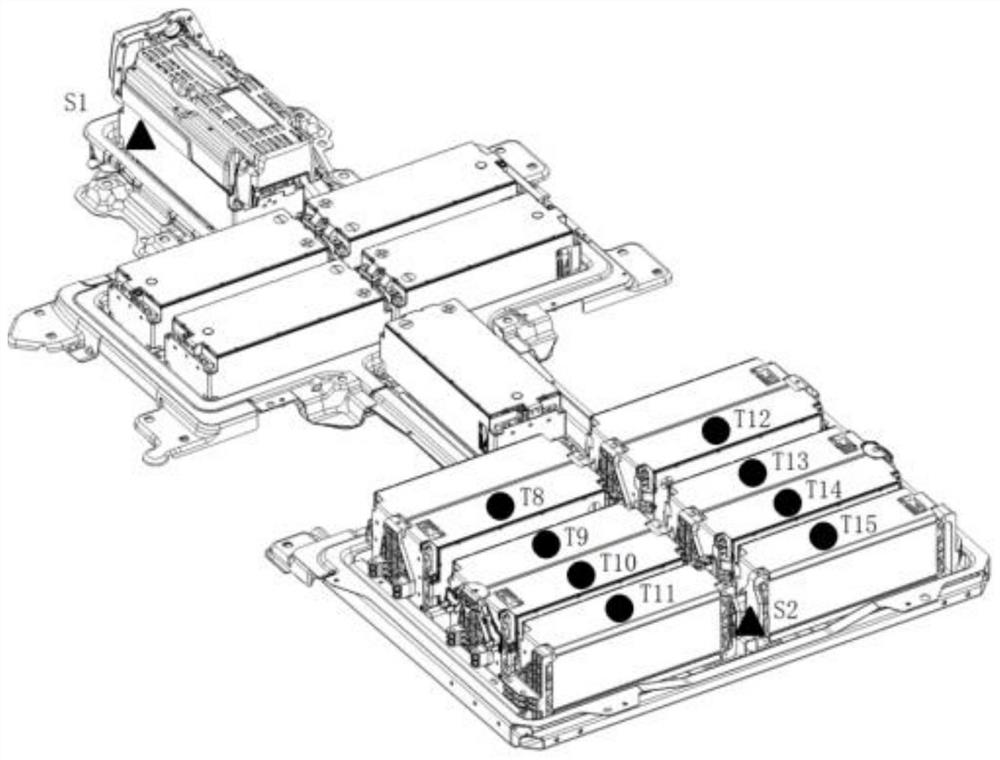

[0048] Wherein, in the lithium battery thermal runaway detection system of the present invention, each first temperature sensor is respectively arranged on the surface of each battery cell of each batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com