Cylindrical mirror and coded disc glass bonding device and method based on non-coplanar marking lines

A technology of cylindrical mirror and marking line, which is applied in the field of photodetectors, can solve the problems of high uncertainty in human visual alignment, high parallelism requirements, uniformity error of slit width, etc., to solve the problem of uneven glue thickness Uniformity, improve alignment accuracy, and avoid out-of-tolerance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further elaborated below in conjunction with embodiment.

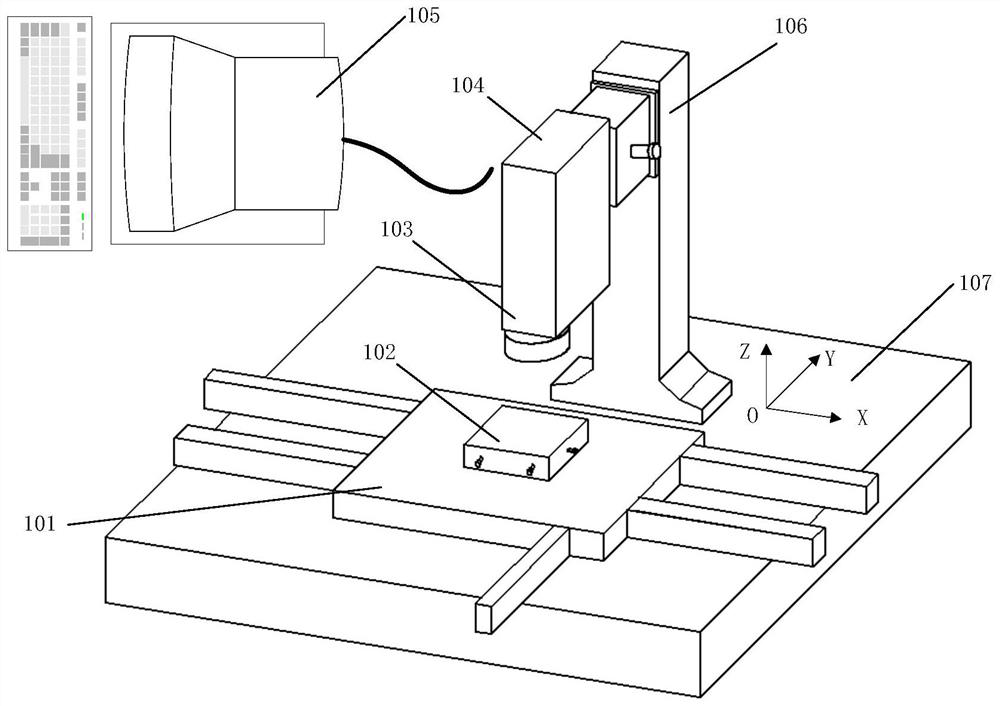

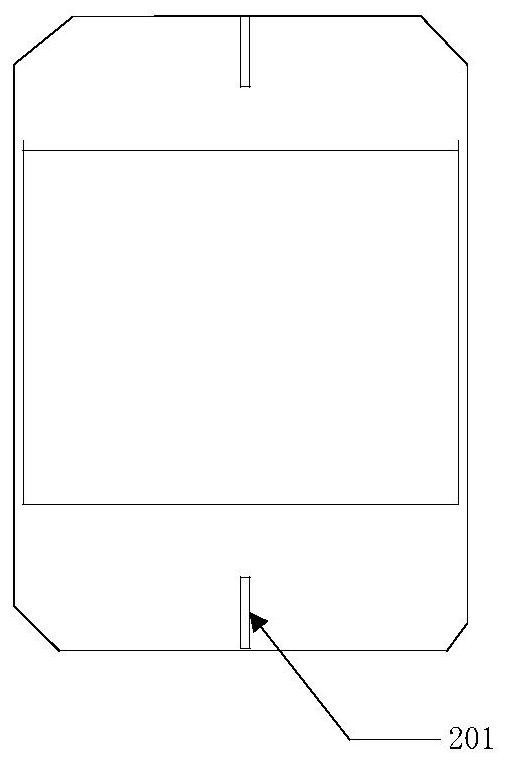

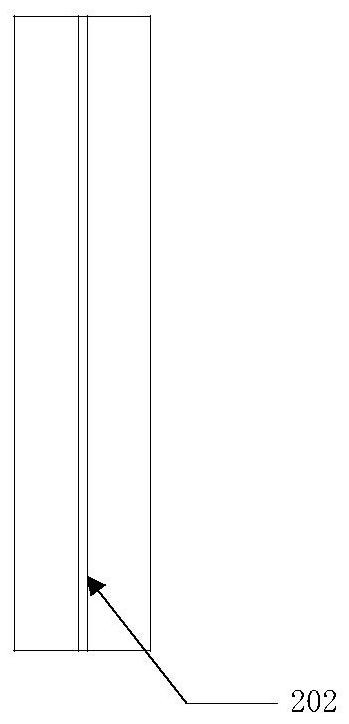

[0043] Such as figure 1 As shown, the present invention provides a cylindrical mirror and code wheel glass alignment and bonding device based on non-coplanar marking lines, the non-coplanar marking lines are respectively the optical slit of the cylindrical mirror and the code wheel 0-0 'marking line, the device includes a two-dimensional mobile platform 101, a code disc cylindrical lens bonding mold 102, a microscopic optical system 103, a CCD camera 104, a computer 105, a column 106, and a base 107;

[0044] Take the upper surface of the base 107 as the XOY plane of the measurement system coordinate system, and the coordinate axis perpendicular to the XOY plane is the Z axis of the measurement coordinate system. Move in the Y direction; the code disc cylindrical mirror bonding mold 102 is located on the two-dimensional mobile platform 101 for stacking the code disc and the cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com