Design method of variable-density lattice structure with three-period minimal curved surface for additive manufacturing

A technology of extremely small curved surface and lattice structure, applied in the field of three-period minimal curved surface variable density lattice structure design field of additive manufacturing, can solve the problems of low efficiency and numerical instability of topological structure, so as to improve the structural strength and improve the Variable density lattice structure strength, to achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

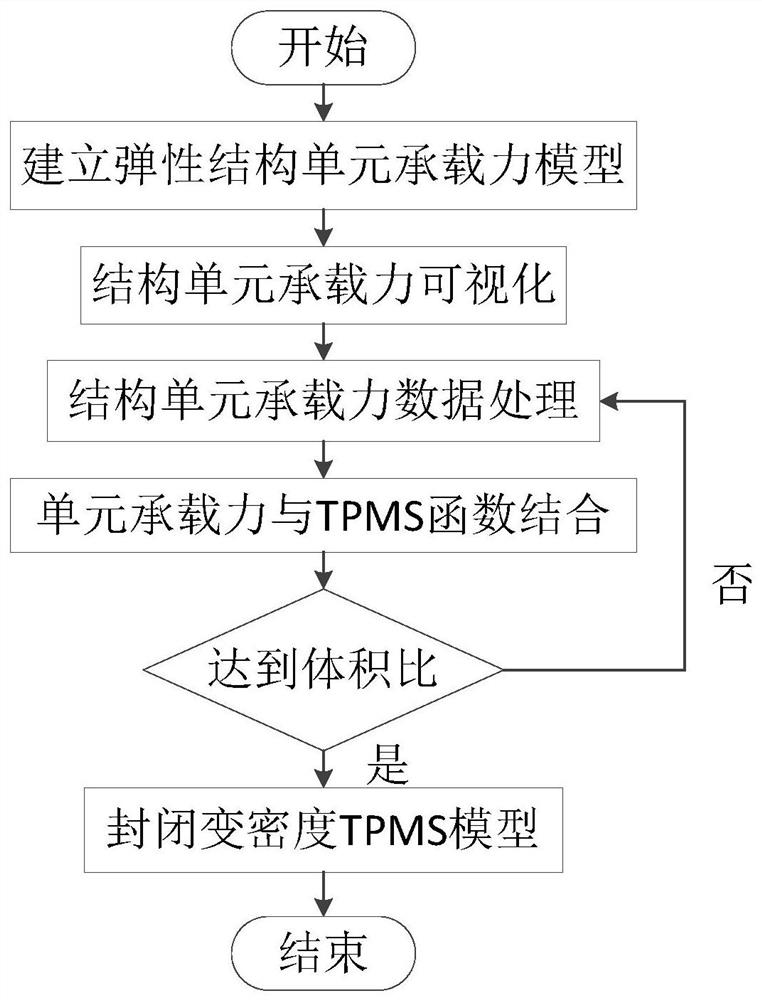

Method used

Image

Examples

Embodiment 1

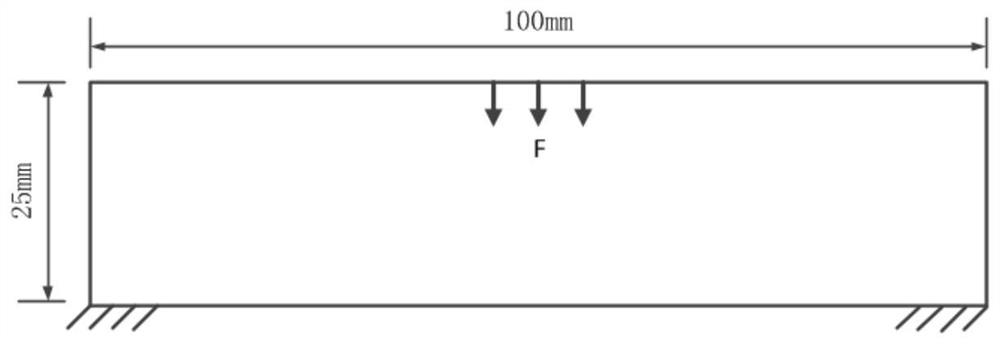

[0091] Taking a rectangular plate with a length of 100 mm and a width of 50 mm as an example, the restraint load is as follows: figure 2 shown.

[0092] The specific operation steps are as follows:

[0093] S1. Establish a finite element model of a rectangular flat elastic structure, divide the mesh size into 5mm×5mm, and apply constraints and loads.

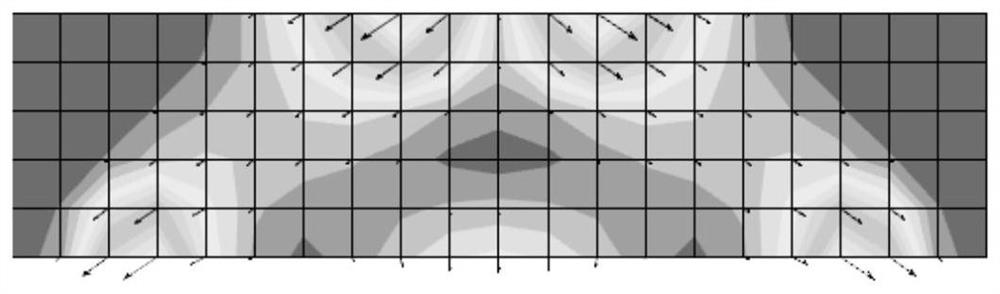

[0094] S2. Based on the static balance principle of elastic structure and the "life and death" state technology of the unit, design the method of extracting the bearing capacity of the unit;

[0095] S21. Determine the load boundary and constraint boundary of the elastic continuum, and calculate the anti-support force f of the constraint boundary i and the nodal displacement δ at the load boundary 1 ;

[0096] S22. Remove the attention area of the elastic continuum, and set the load boundary by node displacement δ 1 load, and calculate the constraint boundary anti-support force at this time again as

[0097] S23. The ...

Embodiment 2

[0110] Taking a cuboid with a length of 100mm, a width of 50mm, and a height of 25mm as an example, the restraint load is as follows: Image 6 shown.

[0111] The specific operation steps are as follows:

[0112] S1. Establish the finite element model of the cuboid elastic structure, divide the mesh size into 5mm×5mm×5mm, and apply constraints and loads.

[0113] S2. Based on the static balance principle of elastic structure and the "life and death" state technology of the unit, design the method of extracting the bearing capacity of the unit;

[0114] S21. Determine the load boundary and constraint boundary of the elastic continuum, and calculate the anti-support force f of the constraint boundary i and the nodal displacement δ at the load boundary 1 ;

[0115] S22. Remove the attention area of the elastic continuum, and set the load boundary by node displacement δ 1 load, and calculate the constraint boundary anti-support force at this time again as

[0116] S23. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com