Transparent conductive paper capable of being directly printed

A transparent conductive and transparent paper technology, applied in conductive materials dispersed in non-conductive inorganic materials, paper, papermaking and other directions, can solve problems such as unfavorable large-scale promotion of transparent electronic materials, poor product conductivity repeatability, and complicated operation. Low surface roughness, high reproducibility, simple operation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

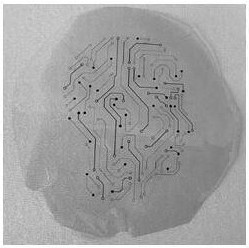

Image

Examples

Embodiment 1

[0024] In the present invention, the crude arabinoxylan extract is firstly extracted from the psyllium seed husk by hot water extraction method, and the pure arabinoxylan product is obtained through repeated redissolving and deproteinization treatment by Sevage method. Prepare the arabinoxylan solution from the product, and dry it in a constant temperature and constant humidity drying box to form a transparent paper; mix the nano-conductive medium evenly with the commercial ink to form a conductive nano-ink, and print the conductive nano-ink directly on the surface of the arabinoxylan film Thus, transparent conductive paper was successfully prepared, and the specific steps are as follows:

[0025] (1) Extraction of arabinoxylan: Pulverize the psyllium seed husk with a particle size of 100 mesh; accurately weigh 5.0 g of the psyllium seed husk powder, add 200 mL of distilled water, mix well and place in a 50 °C water bath extract in a 10000 rpm centrifuge for 10 min, separate t...

Embodiment 2

[0032] (1) Extraction of arabinoxylan: crush the psyllium seed husk, and the particle size is 100 mesh; accurately weigh 5.0 g of the psyllium seed husk powder, add 25 mL of distilled water, mix well and place in a 70 °C water bath extract in a 10000 rpm centrifuge for 10 min, separate the supernatant from the precipitate, and the supernatant is the crude arabinoxylan extract; place the crude arabinoxylan extract in Perform drying treatment in a freeze dryer to obtain coarse arabinoxylan powder.

[0033] (2) Purification of arabinoxylan: first redissolve the crude arabinoxylan powder in distilled water, centrifuge in a centrifuge at 10,000 rpm for 10 min to remove the precipitate, and place the supernatant in a freeze dryer for drying Obtain a dry reconstitution sample; repeat the above reconstitution operation 5 times; weigh 2.0 g of the sample powder that has been reconstituted for 5 times and dissolve it in 200 mL distilled water to prepare a 1% concentration of arabinoxyla...

Embodiment 3

[0038] (1) Extraction of arabinoxylan: crush the psyllium seed husk, and the particle size is 100 mesh; accurately weigh 5.0 g of the psyllium seed husk powder, add 250 mL of distilled water, mix well and place in a water bath at 40 °C extract in a 10000 rpm centrifuge for 10 min, separate the supernatant from the precipitate, and the supernatant is the crude arabinoxylan extract; place the crude arabinoxylan extract in Perform drying treatment in a freeze dryer to obtain coarse arabinoxylan powder.

[0039] (2) Purification of arabinoxylan: first redissolve the crude arabinoxylan powder in distilled water, centrifuge in a centrifuge at 10,000 rpm for 10 min to remove the precipitate, and place the supernatant in a freeze dryer for drying Obtain a dry reconstitution sample; repeat the above reconstitution operation 3 times; weigh 2.0 g of the sample powder that has been reconstituted three times and dissolve it in 200 mL distilled water to prepare a 1% concentration of arabino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap