Fuel cell flow field plate and fuel cell

A fuel cell and flow field plate technology, which is applied in the direction of fuel cells, fuel cell components, circuits, etc., to achieve the effects of reducing concentration polarization, facilitating discharge, and enhancing heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

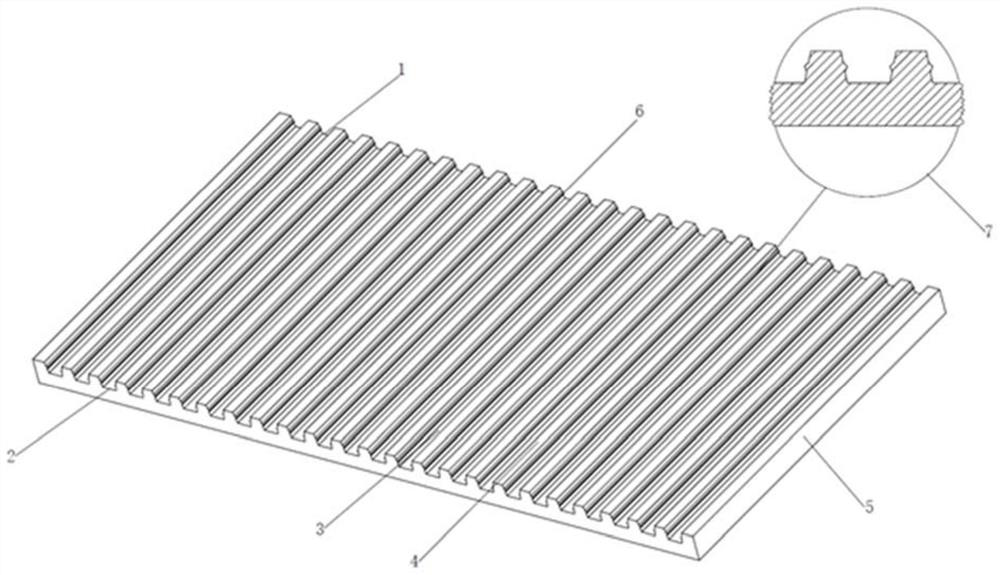

[0033] Such as figure 1 As shown, a fuel cell flow field plate according to the present invention is mainly suitable for hydrogen-air fuel cells and hydrogen-oxygen fuel cells, and the flow field plate is made of graphite material, including an air inlet, an air outlet, and a flow channel , ridges and bosses on either side of the runner. The air inlet and the air outlet are connected through flow channels on the flow field plate. The flow channel adopts parallel flow channel, the cross section of the flow channel adopts trapezoidal cross section, and the bosses on both sides of the flow channel adopt triangular bosses. When the flow field plate of the present invention is in operation, the gas is passed into the inlet 1, the gas moves and reacts along the flow channel 3, and reaches the gas outlet 2 to discharge unreacted gas and water generated by reaction. The 4 in the flow field plate 5 are ridges, and the ridges 4 and the flow channels 3 are alternately arranged to suppo...

Embodiment 2

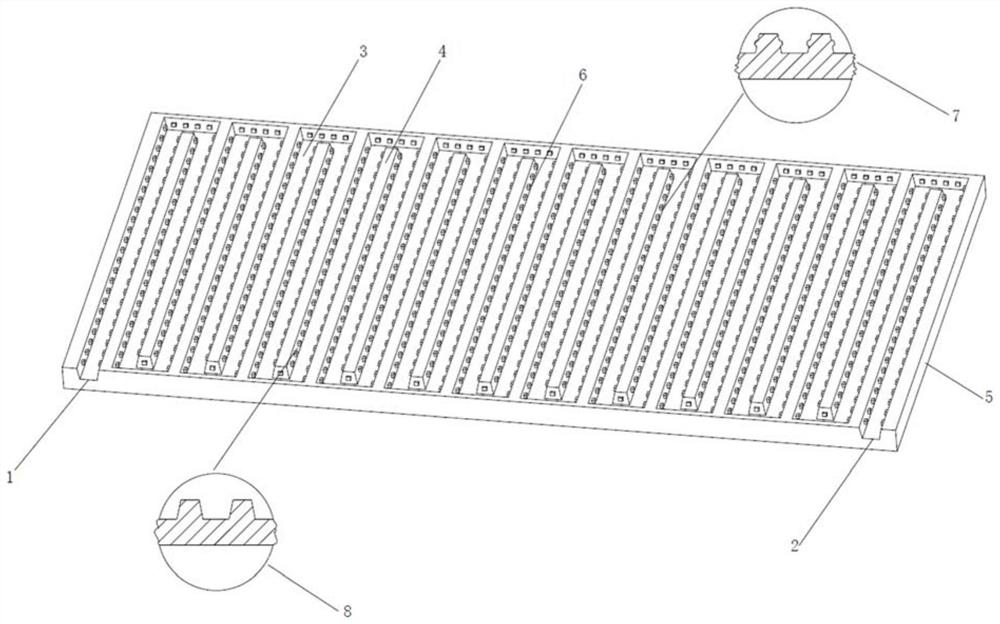

[0035] Such as figure 2 As shown, a fuel cell flow field plate according to the present invention is mainly suitable for hydrogen-air fuel cells and hydrogen-oxygen fuel cells, and the flow field plate is made of graphite material, including an air inlet, an air outlet, and a flow channel , ridges and bosses on either side of the runner. The air inlet and the air outlet are connected through flow channels on the flow field plate. The runner adopts a serpentine runner, the cross section of the runner adopts a trapezoidal cross section, and the bosses on both sides of the runner adopt rectangular bosses. When the flow field plate of the present invention is in operation, the gas is passed into the inlet 1, the gas moves and reacts along the flow channel 3, and reaches the gas outlet 2 to discharge unreacted gas and water generated by reaction. The 4 in the flow field plate 5 are ridges, and the ridges 4 and the flow channels 3 are alternately arranged to play the role of supp...

Embodiment 3

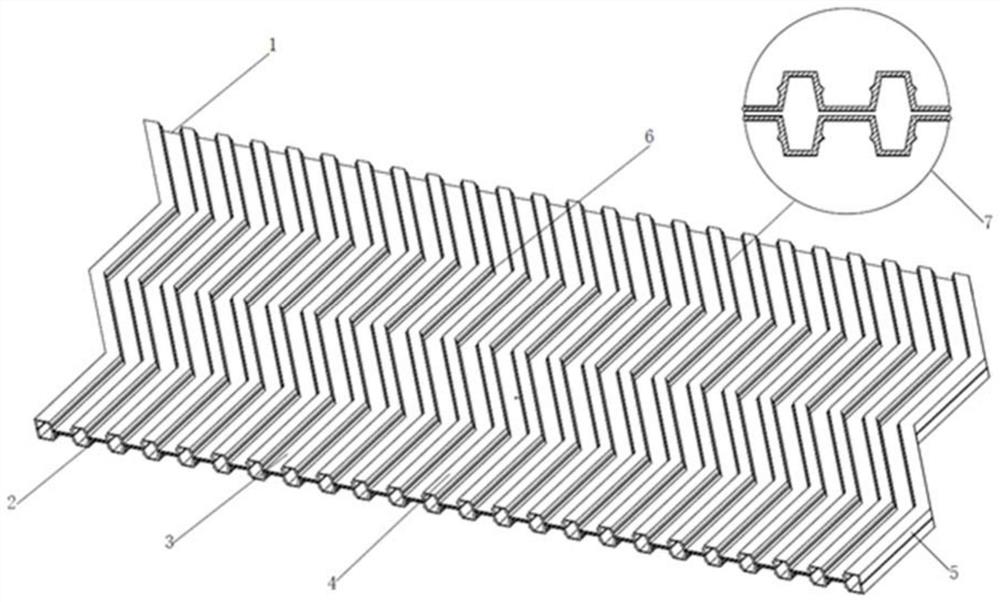

[0037] Such as image 3 As shown, a fuel cell flow field plate according to the present invention is mainly suitable for hydrogen-air fuel cells and hydrogen-oxygen fuel cells, and the flow field plate is made of metal materials, including an air inlet, an air outlet, and a flow channel , ridges and bosses on either side of the runner. The air inlet and the air outlet are connected through flow channels on the flow field plate. The flow channel adopts a folded flow channel, the cross section of the flow channel adopts a trapezoidal cross section, and the bosses on both sides of the flow channel adopt triangular bosses. When the flow field plate of the present invention is in operation, the gas is passed into the inlet 1, the gas moves and reacts along the flow channel 3, and reaches the gas outlet 2 to discharge unreacted gas and water generated by reaction. The 4 in the flow field plate 5 are ridges, and the ridges 4 and the flow channels 3 are alternately arranged to suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com