MMC sub-module with fault current blocking and self-voltage-sharing capabilities

A fault current and sub-module technology, applied to electrical components, output power conversion devices, AC power input conversion to DC power output, etc., can solve problems such as difficult to block DC fault current and long restart time, and achieve favorable Fast recovery, simplified difficulty, and the effect of achieving capacitor voltage balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

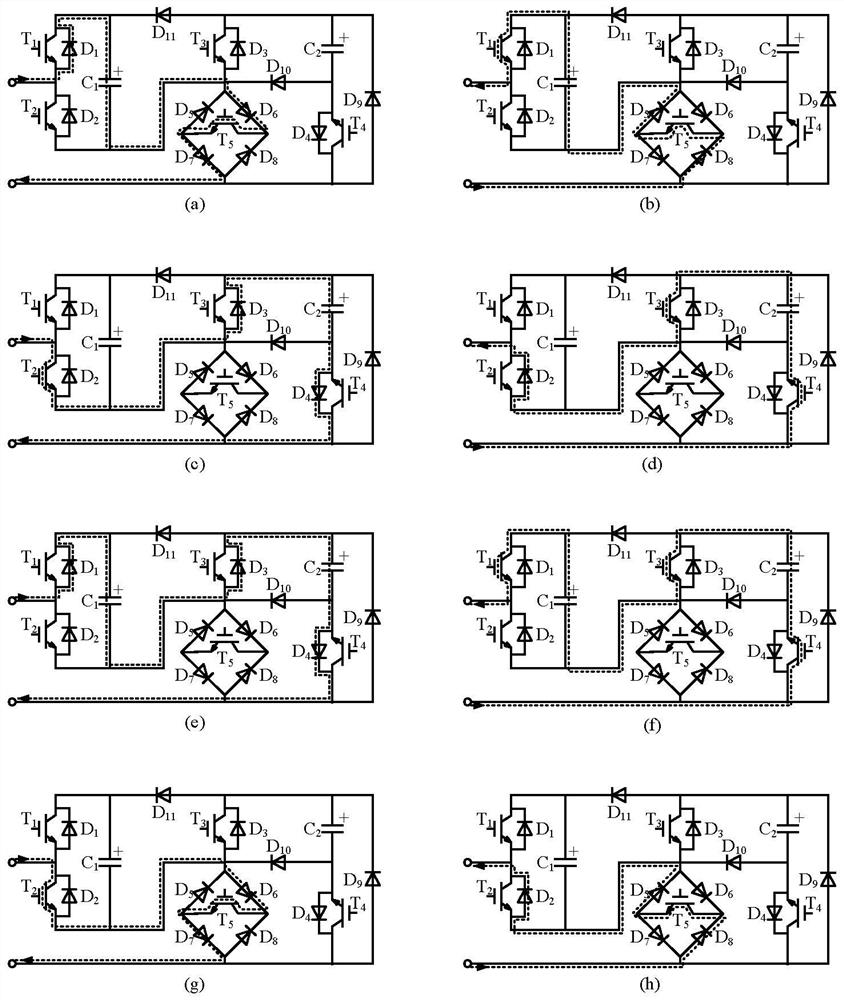

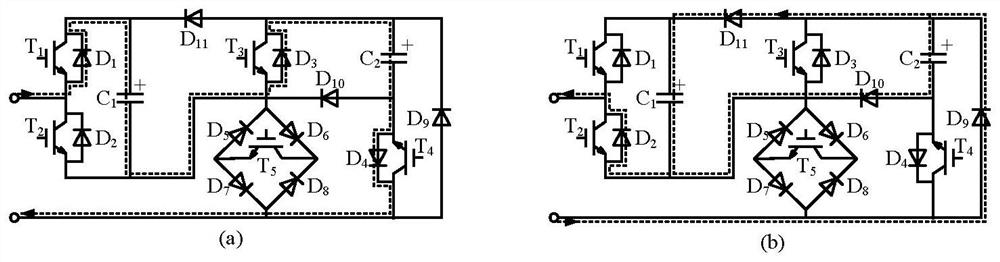

[0018] The embodiments will be described in detail below in conjunction with the accompanying drawings.

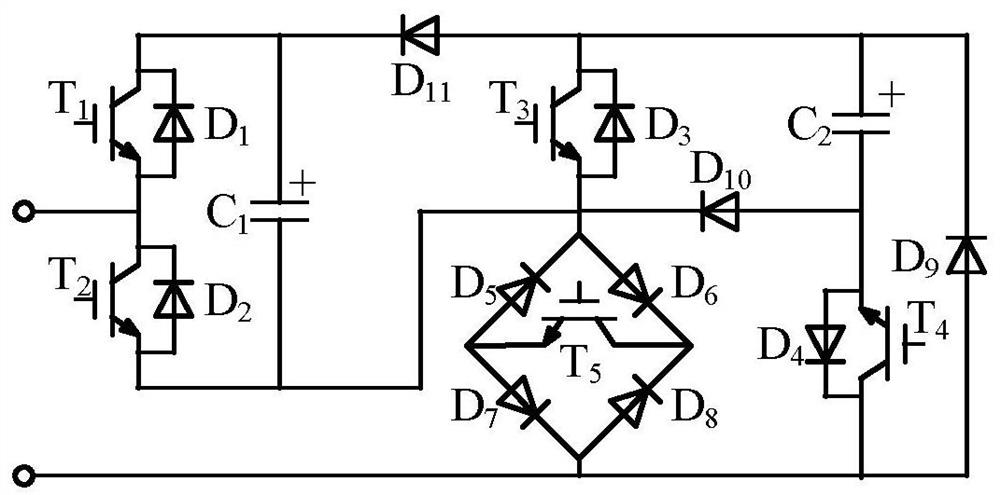

[0019] figure 1 One embodiment of the MMC sub-module of the present invention is shown. Switch tube T 1 , T 2 and diode D 1 with D 2 and capacitance C 1 Form a half-bridge sub-module, in which the switching tube T 1 with T 2 Connect the capacitor C 1 the anode and cathode of the diode D 1 with D 2 Respectively with the corresponding switching tube T 1 with T 2 anti-parallel, switching tube T 1 with T 2 An outlet end of the MMC sub-module of the present invention is connected to the connection between them. Switch tube T 3 , T 4 , T 5 and diode D 3 ~D 8 and capacitance C 2 form another sub-module, the diode D 5 ~D 8 with switching tube T 5 together form a bidirectional switch, the diode D 3 with D 4 Respectively with the corresponding switching tube T 3 , T 4 anti-parallel. The upper end of the bidirectional switch is connected to the capacitor C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com