Efficient heat dissipation structure for solar inverter

A technology of heat dissipation structure and inverter, which is applied in the direction of transforming equipment structural parts, cleaning methods and utensils, chemical instruments and methods, etc. Efficient, easy to shake off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

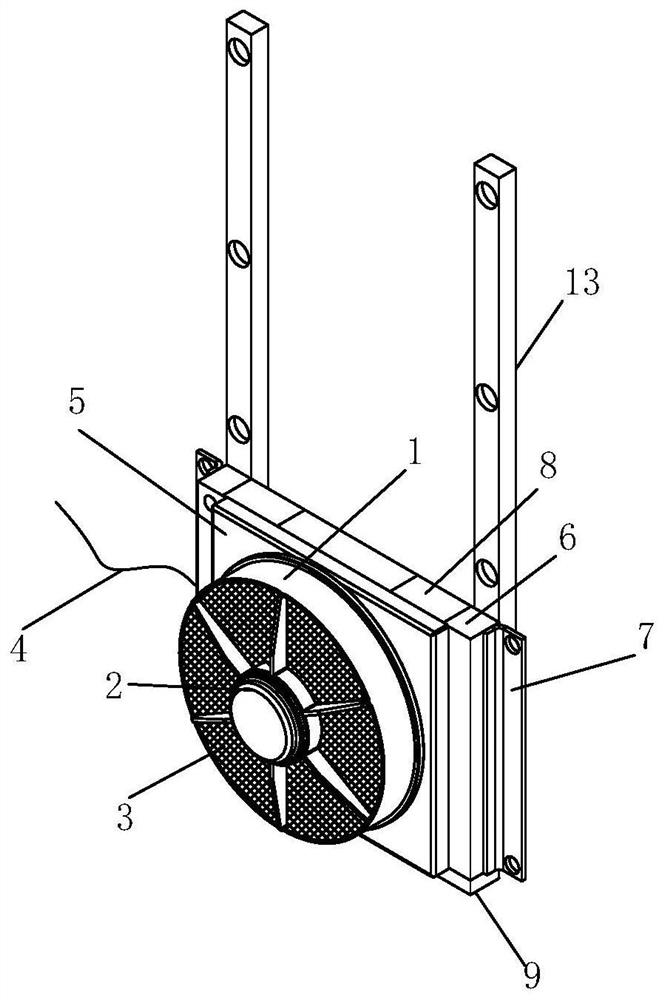

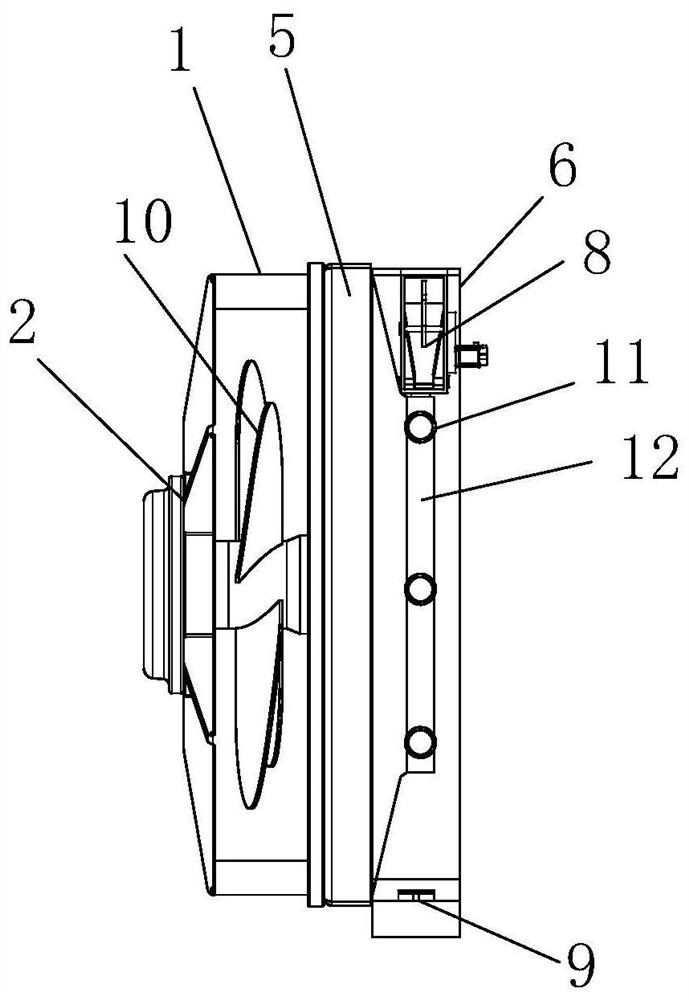

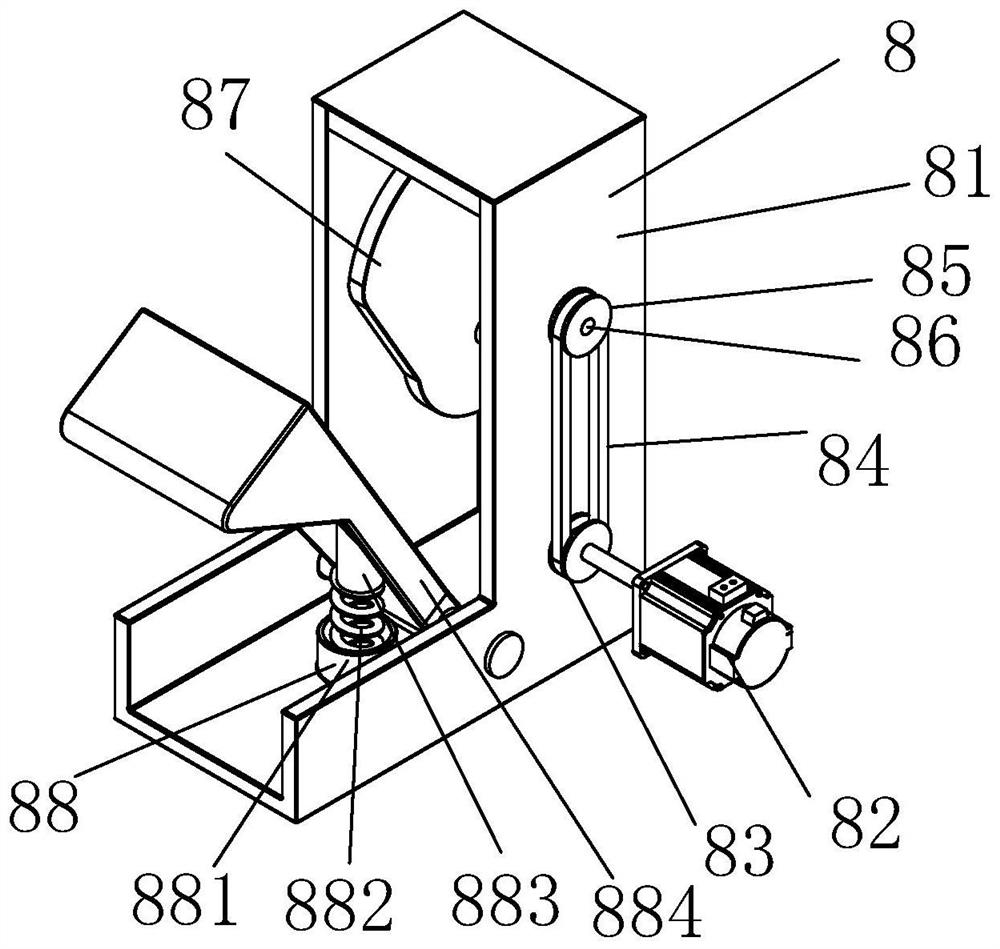

[0029] see figure 1 and figure 2 , the present invention provides a high-efficiency heat dissipation structure for solar inverters through improvement, including a fixed cover 1, a stabilizer 2 is fixed on the front surface of the fixed cover 1, a spacer 3 is embedded inside the stabilizer 2, and the left lower end of the fixed cover 1 The power line 4 is installed, the back of the fixed cover 1 is fixed to the back plate 5, the back of the back plate 5 is connected to the fixed box 6, the left and right sides of the fixed box 6 are welded with the mounting parts 7, and the fan 10 is arranged in the middle of the fixed cover 1 , and the fan 10 is electrically connected to the power line 4, the left and right sides of the fixed box 6 are fixed by springs 11 and fins 12, the back of the fixed box 6 is welded with a mounting rod 13 near the outer edge, and the left and right ends of the top of the fixed box 6 are fixed. There is a cleaning device 8, and the bottom of the fixed ...

Embodiment 2

[0034]The present invention provides a high-efficiency heat dissipation structure for solar inverters through improvement. There are six groups of springs 11, and three groups are installed on both sides of the fixed box 6, effectively making the fins 12 assist in the heat dissipation under the condition of force. Shaking; the distance between the top of the toggle block 87 and the inner top of the housing 81 is 3cm to prevent collision with the housing 81 during the rotation of the toggle block 87; the top of the fixed plate 91 is bonded with a layer of 2mm thick Silicone layer to prevent leakage during collection.

[0035] The present invention provides a high-efficiency heat dissipation structure for a solar inverter through improvement, and its working principle is as follows;

[0036] First, when the heat dissipation structure needs to be used, first install the heat dissipation structure to the position where it needs to be used, then connect the power line 4 to the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com