Efficient graphene nano-modified heat dissipation material and preparation method thereof

A nano-modification and heat dissipation material technology, applied in the field of heat dissipation materials, can solve the problems of increased processing difficulty, poor dispersion, and inability to show the excellent characteristics of graphene, and achieve the effect of wide application and low interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a kind of preparation method of high-efficiency graphene nano-modified heat dissipation material, and it comprises following process:

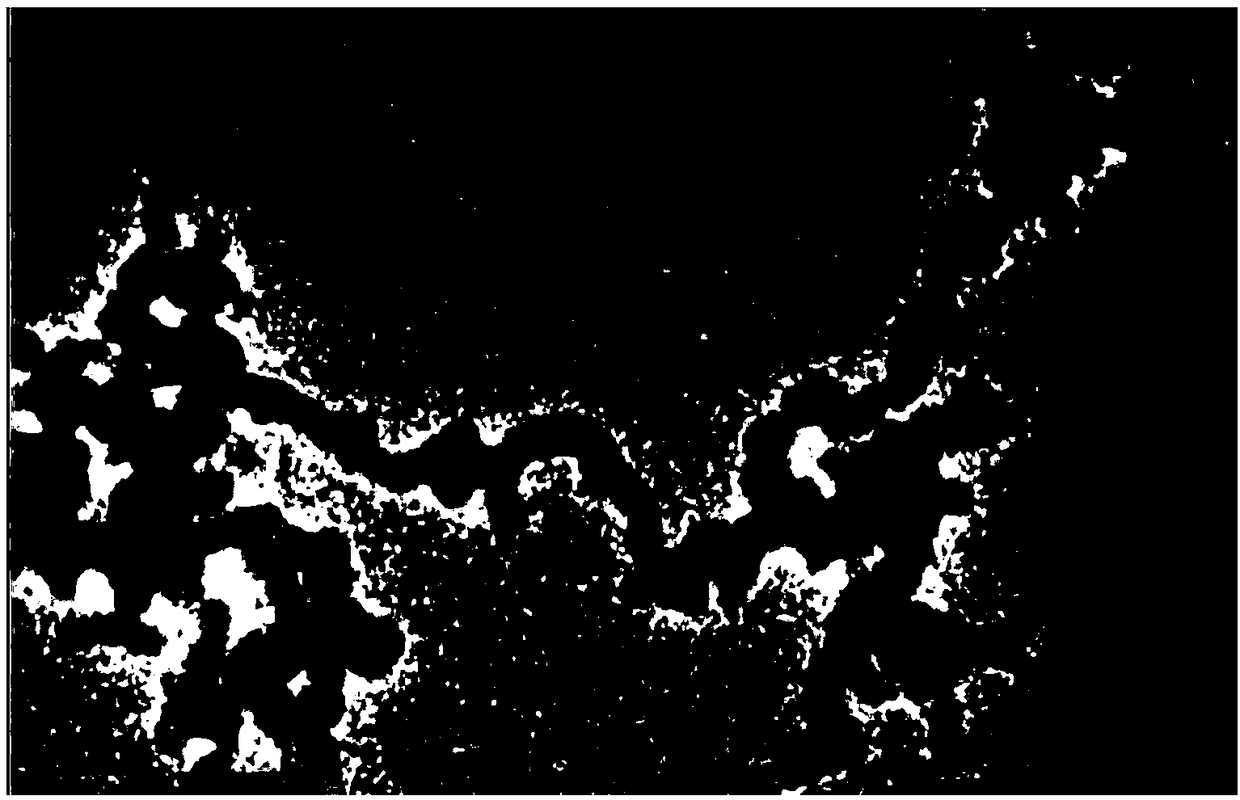

[0026] Step 1: Prepare graphene: prepare by Hummers method and thermal reduction method, first prepare graphene oxide by Hummers method, and thermally reduce graphene oxide to graphene.

[0027] The preparation of graphene oxide by the Hummers method comprises the following steps: Low-temperature reaction: put a dry container (such as a large beaker) in an ice-water bath, add 98% concentrated sulfuric acid (H 2 SO 4 ) 110mL, turn on the cooling circulation pump to keep the temperature of the container at -1°C-1°C, slowly add 5g of flake graphite (-100 mesh) while stirring, continue stirring, and slowly add 2.5g of sodium nitrate (NaNO 3 ), continue to stir for about 30min, then slowly add potassium permanganate (KMnO 4 ) 15g, continue to stir (1.5 hours - 2 hours) to make it fully react, and the solution...

Embodiment 1

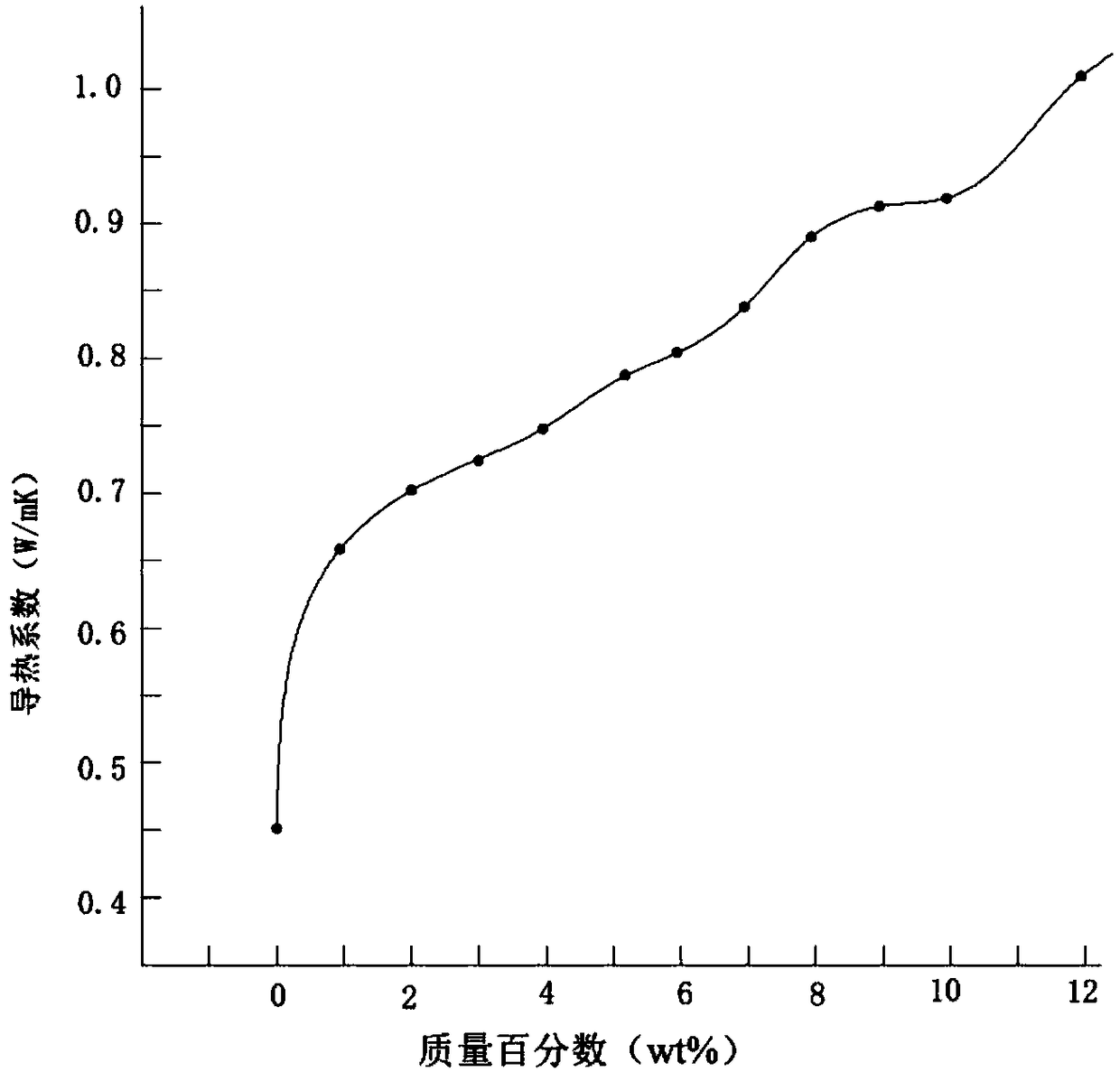

[0049] The following is a specific embodiment to illustrate the graphene nano heat dissipation material: 15 parts of graphene, 3 parts of graphene oxide and 6 parts of nano ceramics (Al 2 o 3 The weight: the weight of aluminum nitride = 5: 3) The graphene nano-modified powder is prepared by the preparation method in step 4, wherein the first solvent used is N,N-dimethylformamide; the graphene nano 6 parts of modified powder, 60 parts of second solvent, 55 parts of high molecular polymer and 10 parts of additives are obtained by ultrasonic blending to obtain graphene nano-heat dissipation material, wherein the content of graphene nano-modified powder is 4.58wt% ( Graphene nano-modified powder / (graphene nano-modified powder + second solvent + polymer + additive) = 4.58%), where the second solvent used is N,N-dimethylformamide , the high molecular polymer is HDPE, and the additive is used to assist in forming the coating, and the additive in this embodiment is a defoamer and a...

Embodiment 2

[0054]The following is another specific embodiment to illustrate the graphene nano heat dissipation material: 20 parts of graphene, 4 parts of graphene oxide and 8 parts of nano ceramics (Al 2 o 3 The weight: the weight of aluminum nitride = 5: 3) The graphene nano-modified powder is prepared by the preparation method in step 4, wherein the first solvent used is N,N-dimethylformamide; the graphene nano 7 parts of modified powder, 75 parts of second solvent, 65 parts of high molecular polymer and 10 parts of additives are obtained by ultrasonic blending to obtain graphene nano-heat dissipation material, wherein the content of graphene nano-modified powder is 4.46wt% ( Graphene nano-modified powder / (graphene nano-modified powder + second solvent + polymer + additive) = 4.46%), wherein the second solvent used is N-methylpyrrolidone, polymer polymer The material is PET, and the additive is used to assist in forming the coating, and the additive in this embodiment is a defoamer an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com