Anti-knotting winding device for cable processing

A winding device and cable technology, which is applied to the transmission parts, transportation and packaging, and thin material processing, etc., can solve the problems of uneven force on equipment, low winding efficiency, poor balance, etc., to avoid excessive temperature, Improve production efficiency and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

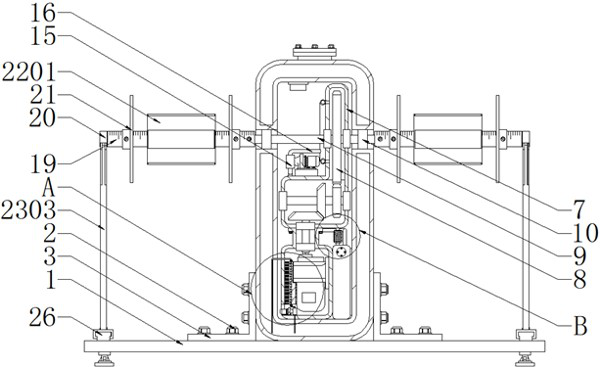

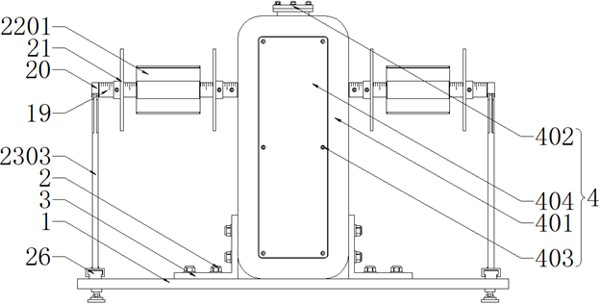

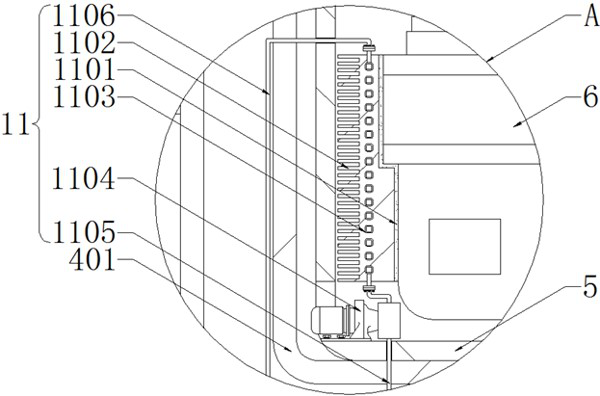

[0029] see Figure 1-2, the present invention provides a technical solution: an anti-knot cable winding device for processing, including a bottom frame 1 and an output shaft 9, a bolt-2 is arranged on the outside of the bottom frame 1, and the outside of the bolt-2 is installed There is an angle iron 3, and a liquid storage assembly 4 is installed on the outside of the angle iron 3, and the liquid storage assembly 4 includes a tank body 401, a tank cover 402, bolts 2 403 and a sealing plate 404, and a tank cover 402 is installed on the outside of the tank body 401 , and the outer front end of the tank body 401 is provided with a second bolt 403, and a sealing plate 404 is installed on the outside of the second bolt 403. The central axis coincides with each other, and the shape of the tank body 401 is rectangular. The bottom of the inner wall of the liquid storage assembly 4 is provided with a housing 5, and the inner wall of the housing 5 is equipped with a motor 6, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com