Impedance threshold level sensor

A sensor and material level technology, which is applied to the liquid level indicator, instrument, liquid level indicator and other directions of physical variable measurement, and can solve the problem that the resonance point cannot be clearly formed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Unless otherwise stated, the same reference numerals in the figures refer to the same components with the same function.

[0044] To simplify the drawings, in Figure 4 to Figure 6 The electronics unit 101 and the signal processing unit 105 are not shown. However, as with prior art, they are included in all exemplary embodiments.

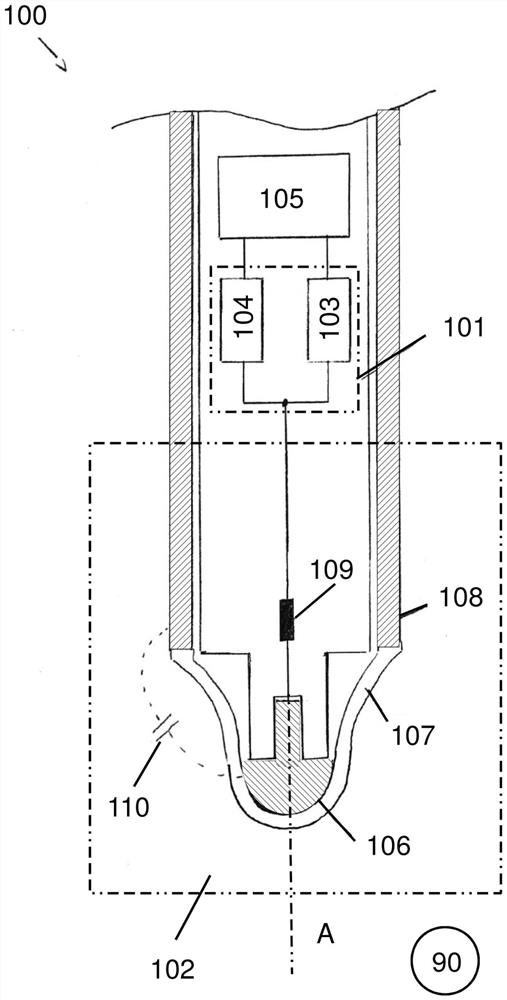

[0045] Figure 4 A first exemplary embodiment of an impedance point level sensor 100 according to the present application is shown. In the exemplary embodiment shown, the impedance point level sensor 100 is shown in a simplified cross-sectional view, as used in the prior art.

[0046] according to Figure 4 The impedance sensor 100 has a measuring probe 102, which in the exemplary embodiment is formed by a measuring electrode 106 oriented in the axial direction A and rotationally symmetrical and a reference electrode 108 also oriented in the axial direction A and rotationally symmetric, A measurement capacitor 110 and a discrete inductor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com