Drying system for washing equipment and dish-washing machine

A technology of washing equipment and drying system, which is applied in the direction of washing machine/washing machine for tableware, parts of washing machine/rinsing machine for tableware, automatic detection under the control of dishwasher/rinsing machine, etc., can solve the problem of high energy consumption , to achieve the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

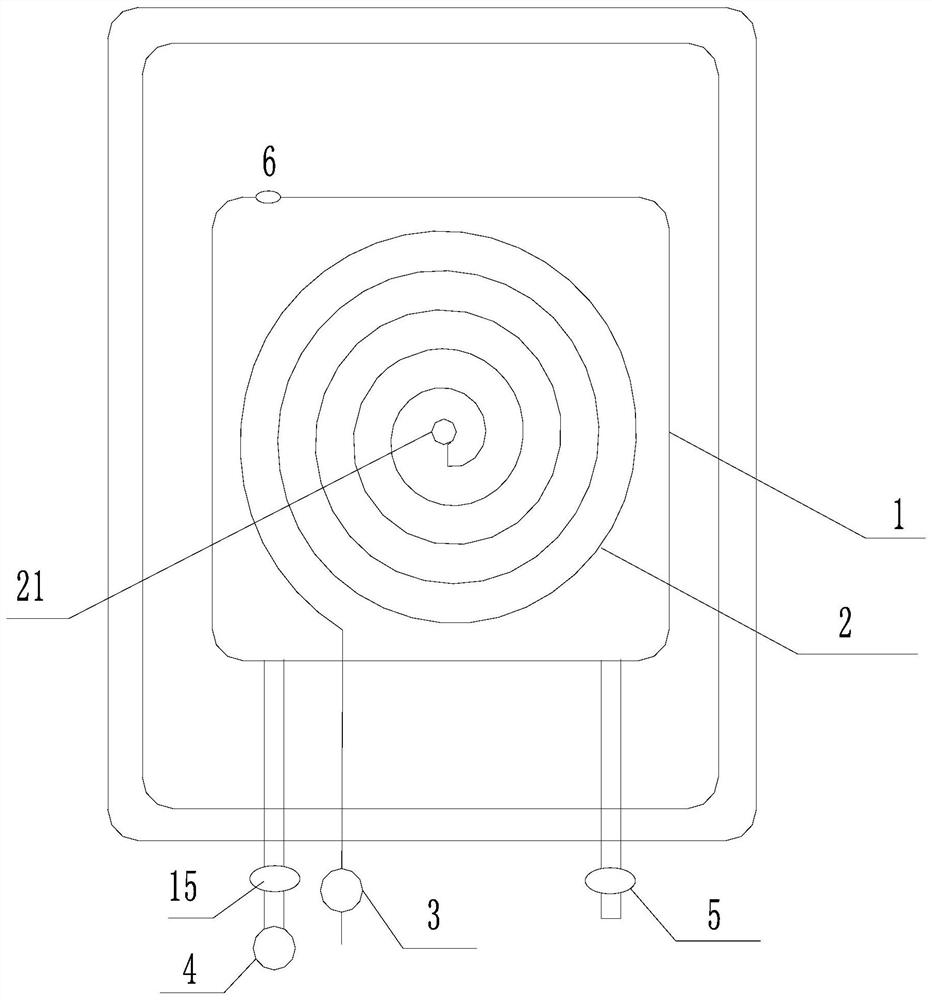

[0039] This embodiment provides a drying system for washing equipment, such as Figure 1-Figure 2 shown, including:

[0040] The water collecting tank 1 is provided with a hot water chamber inside, and an air inlet duct 2 is arranged in the hot water chamber, and the air inlet duct 2 is provided with an air inlet port; the setting method of the air inlet duct 2 itself is not limited too much, As long as the structure is formed separately in the hot water chamber, it can be a straight pipe, a curved pipe, or other shapes. The entrance of air inlet channel 2 is arranged on the side wall of water collecting box 1, thereby can realize the introduction of external cold wind. At the same time, by arranging the blower fan 3, the outside cold wind can be accelerated to enter the inside of the air inlet passage 2, thereby realizing the flow of wind inside the air inlet passage 2;

[0041] The air outlet 21 is arranged on the air inlet channel 2; the location and shape of the air outl...

Embodiment 2

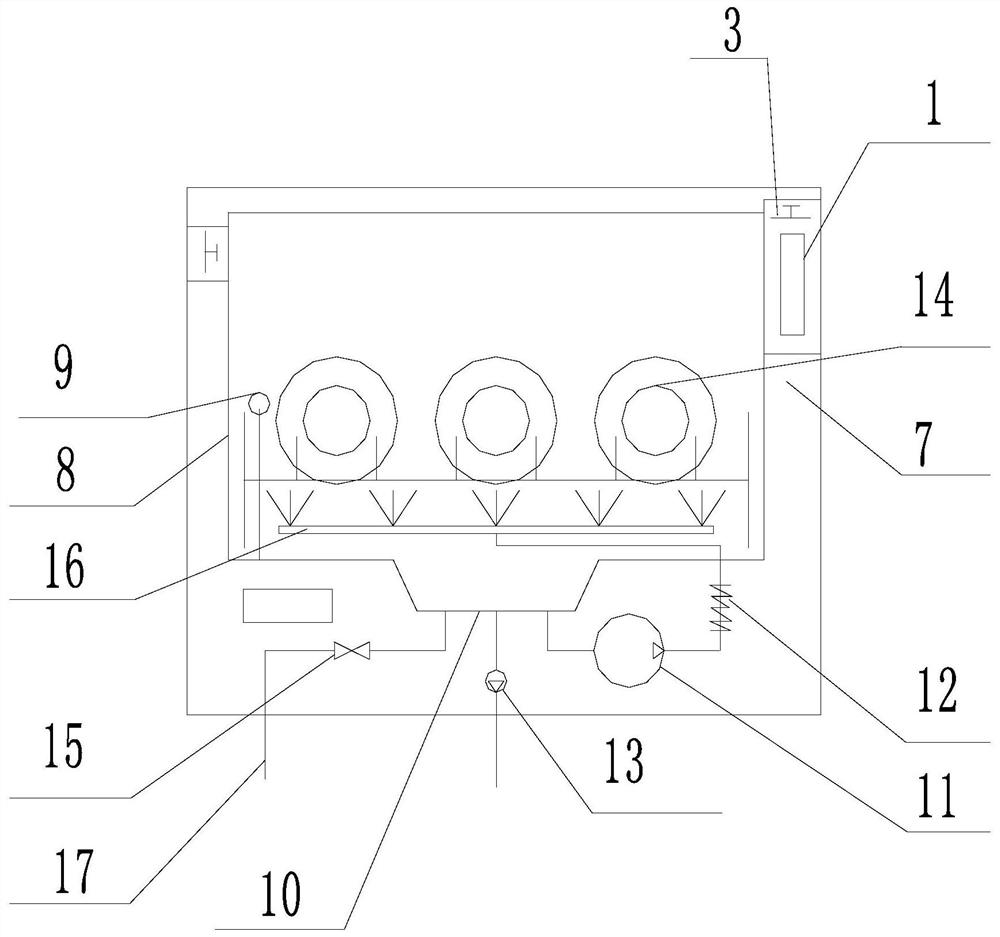

[0051] This embodiment provides a dishwasher, such as figure 2 shown, including:

[0052] Housing 7, housing 7 is provided with door body, realizes putting into and taking out operation to tableware 14 etc. by door body;

[0053] The inner container 8 is arranged inside the housing 7; the washing structures related to the dishwasher are all arranged in the inner container 8, so as to realize the washing operation of the tableware 14 in the inner container 8;

[0054] The drying chamber is arranged between the casing 7 and the inner tank 8, and a fan 3 is arranged on it;

[0055] The drying system for washing equipment provided in Example 1 is set in the drying chamber, the air outlet 21 is set toward the center of the casing 7, and the water inlet pump 4 is suitable for sucking water located in the inner tank 8. water, the water inlet pump 4 is connected with a water inlet pipe 17, and a water inlet valve 15 is arranged on the water inlet pipe 17, so as to realize the on-of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com