A high-life roller press

A roller press, life-span technology, applied in solid separation, chemical instruments and methods, grain processing, etc., can solve the problems of press roller wear and life shortening, and achieve the purpose of improving service life, preventing excessive rigid resistance and reducing wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-4 The application is described in further detail.

[0037] The embodiment of the present application discloses a high-life roller press.

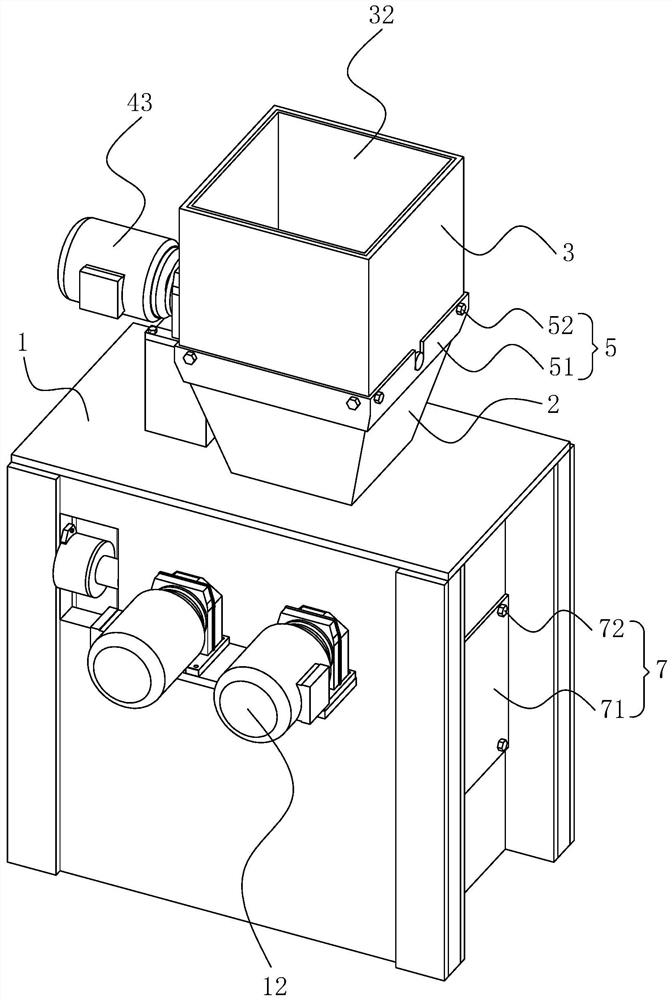

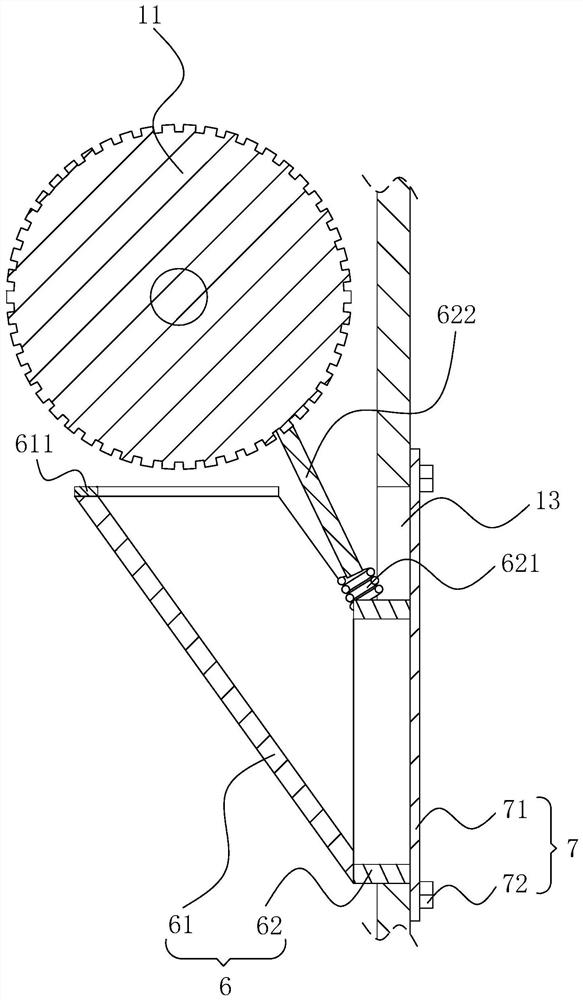

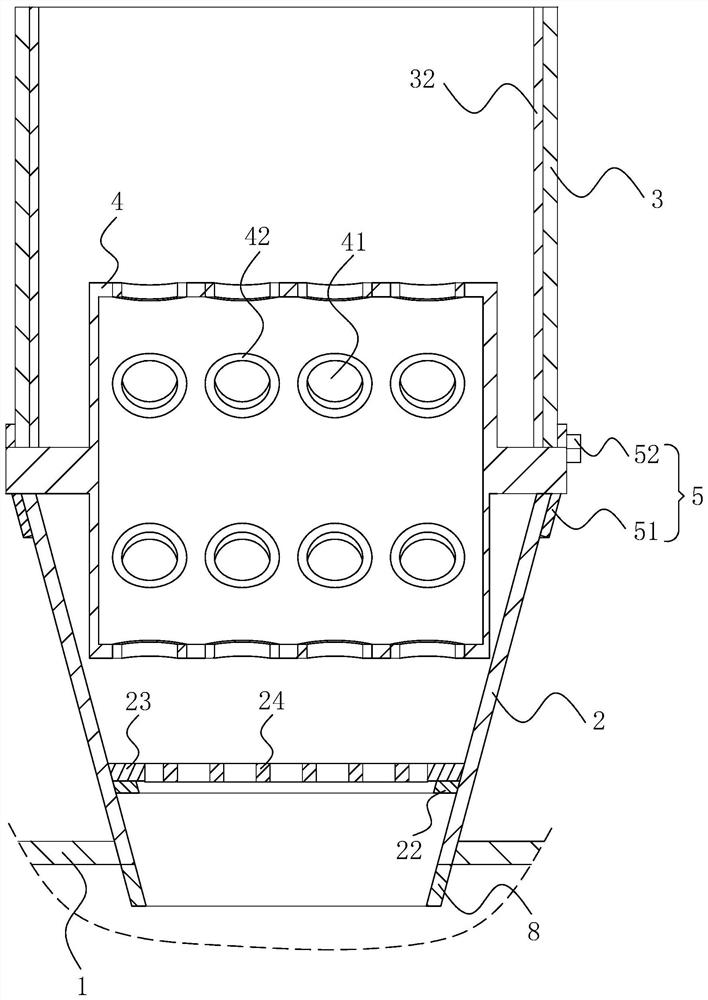

[0038] refer to figure 1 and figure 2 The roller press includes a body 1, a feed hopper 2 connected to the top of the body 1, two pressure rollers 11 that are rotatably connected in the body 1 and rotate in opposite directions, and a first driving device that is fixed on the outside of the body 1 for the pressure rollers 11 to rotate 12, and the outlet opening at the bottom of the body 1. In this embodiment, the first driving device 12 is a motor, and the iron removal mechanism is set at the feed hopper 2. The iron removal mechanism is used to remove the residual metal in the material. A scraping mechanism is provided, and the scraping mechanism is used to scrape off the material adhering to the pressure roller 11, which can greatly reduce the wear of the circumferential side wall of the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com