A stamping device for sheet metal processing

A stamping device and technology of sheet metal parts, applied in the field of sheet metal parts processing, can solve the problems of waste materials stuck in the stamping knife, lack of operation protection measures, inconvenient removal of sheet metal parts, etc., so as to avoid material jamming and facilitate unloading Fast and efficient work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

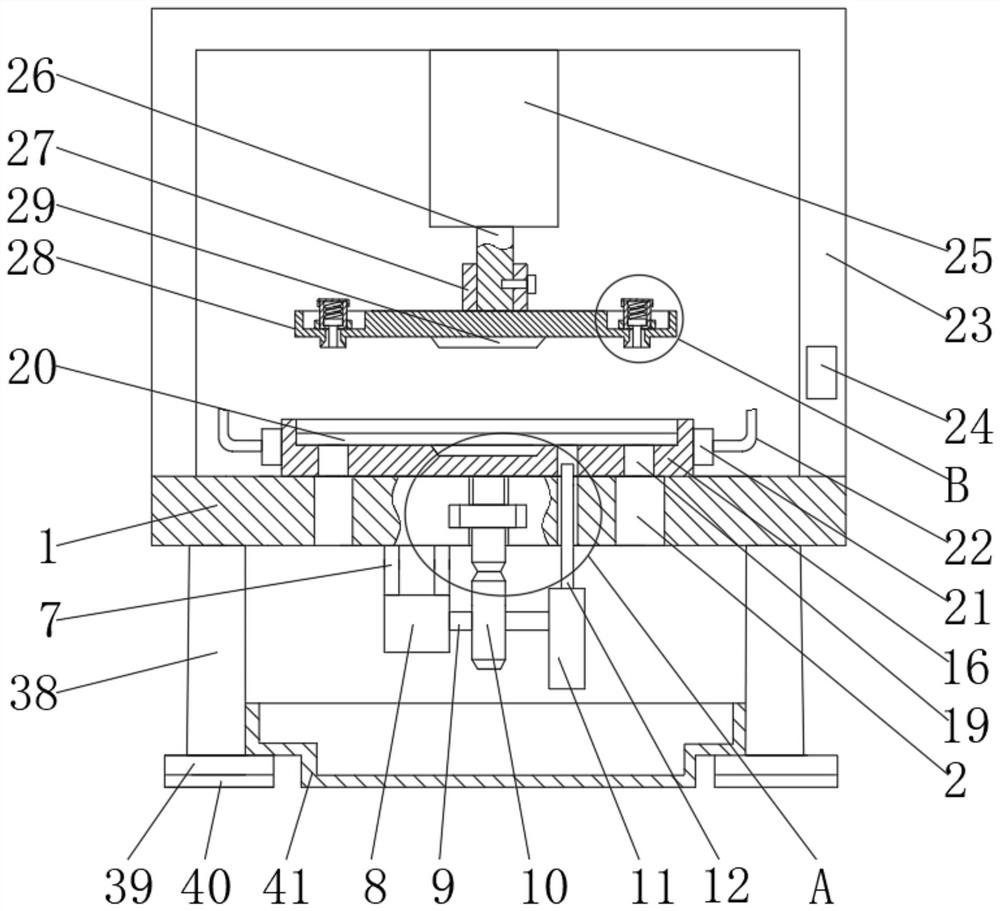

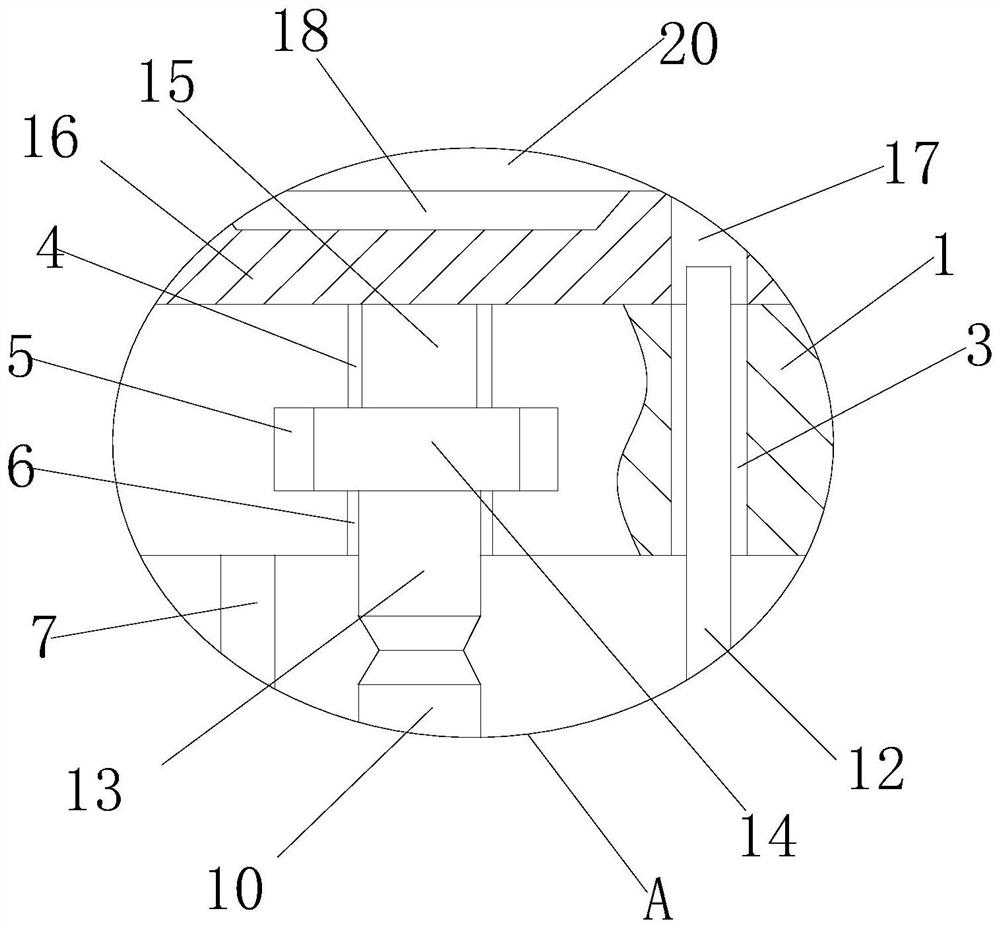

[0034] see Figure 1-7 , a stamping device for sheet metal parts processing, including a support table 1, a discharge chute 2 is opened on the support table 1, a motor frame 7 is fixedly connected to the lower end of the support table 1, and a motor is fixedly installed at the lower end of the motor frame 7 8. It is a servo motor, which belongs to the prior art. The outer side of the rotating shaft 9 of the motor 8 is fixedly installed with a gear 10, the end of the rotating shaft 9 is fixedly installed with a cam 11, and the upper end of the cam 11 is connected to a push rod 12. A rack 13 is engaged, a slider 14 is fixedly connected to the upper end of the rack 13, a connecting block 15 is fixedly connected to the upper end of the slider 14, and a mold base 16 is fixedly connected to the upper end of the connecting block 15, and a groove is opened in the mold base 16 18. A plate 20 is embedded in the die base 16;

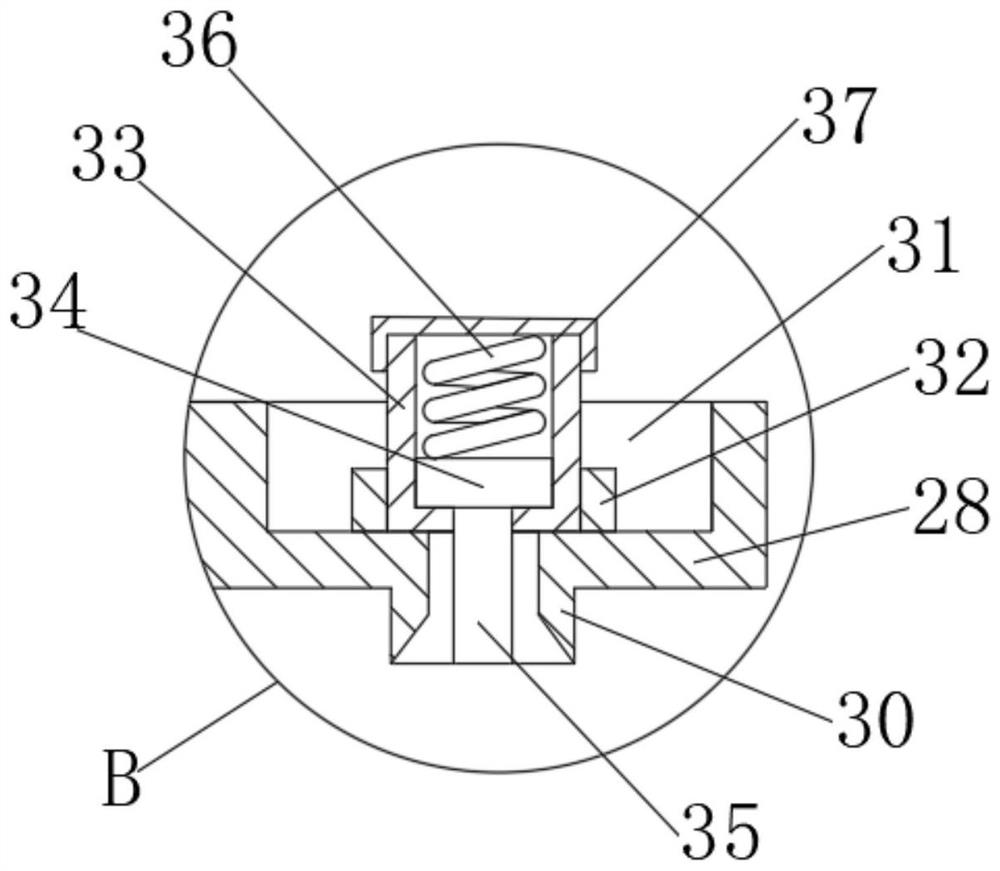

[0035] A heater 21 is fixedly installed on the side of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com