Automatic polishing equipment for mold

An automatic polishing and equipment technology, applied in the field of mold manufacturing, can solve the problems affecting the polishing effect, the polishing tool is rigid, and the workpiece cannot be polished, and achieves the effect of improving the effect, improving the automation, and improving the adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

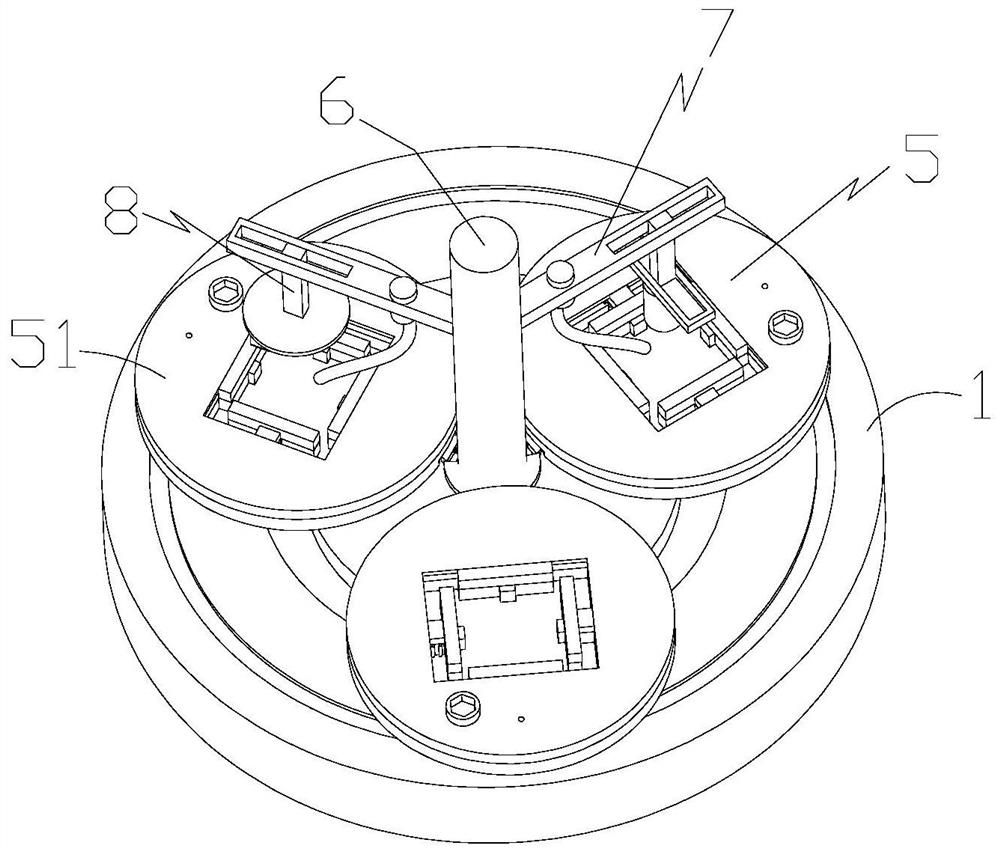

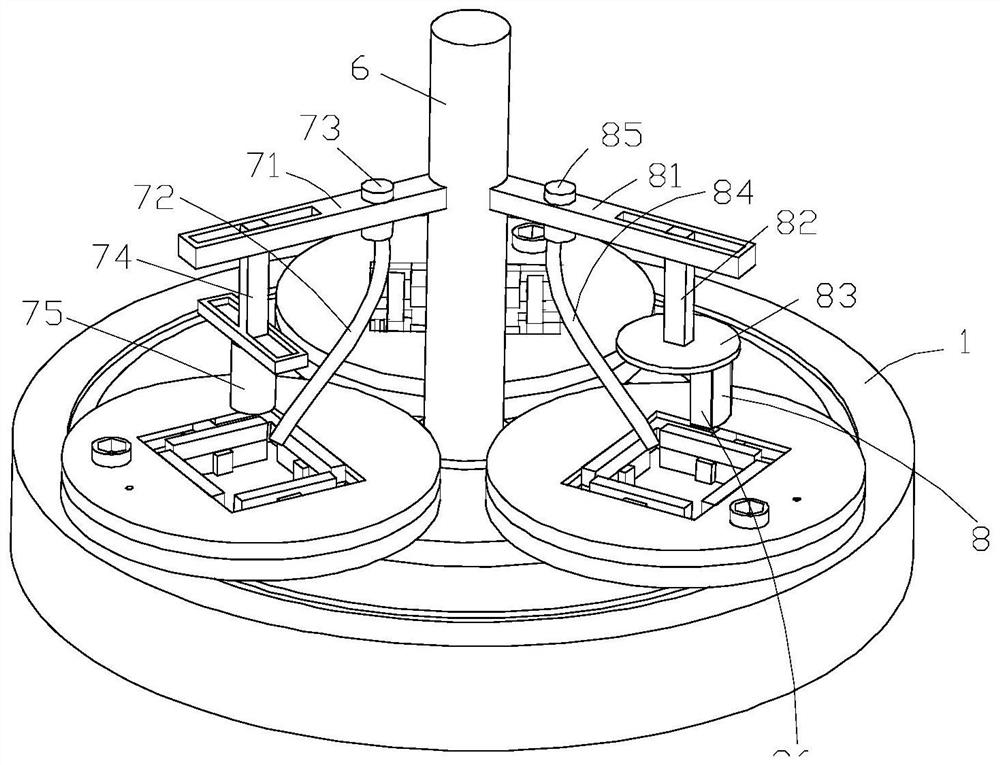

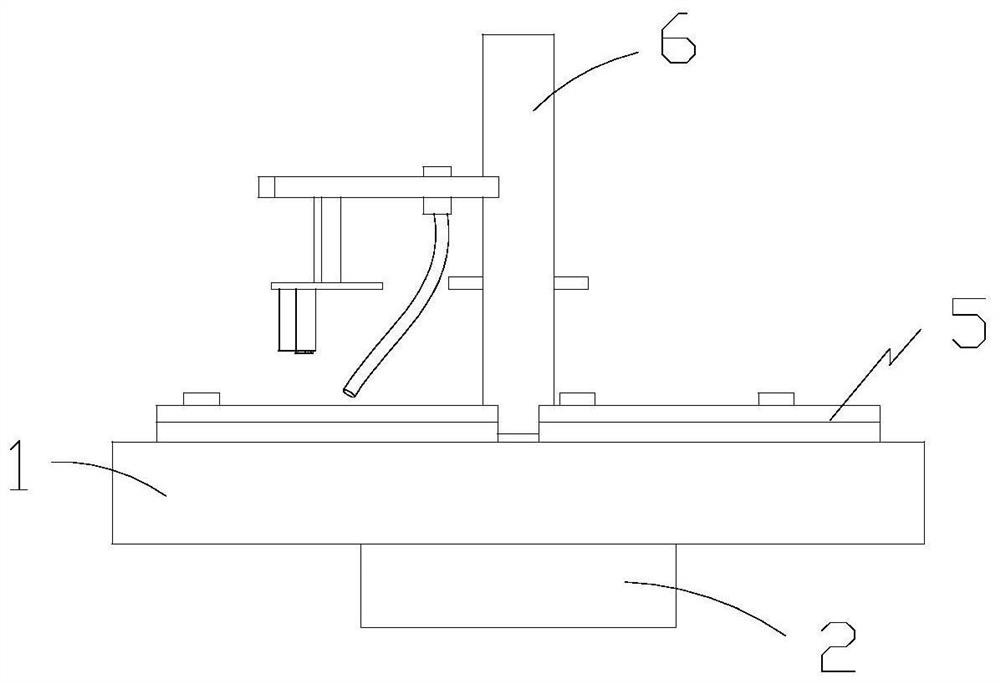

[0042] Such as Figure 1-21 As shown, an automatic mold polishing equipment includes a main body 1, a motor 2, a rotating disk 3, a gear ring 4, a clamping device 5, a fixed roller 6, and a polishing device 7; the polishing device 7 includes a first moving roller 71, The first spray pipe 72, the first timer 73, the second moving stick 74, the whetstone 75, the fine polishing mechanism 8; the cross section of the main body 1 is circular; the motor 2 is located at the bottom of the main body 1, and the motor 2 is directly purchased from the market; the rotating disk 3 is rotatably embedded in the main body 1 and docked with the motor 2; the gear ring 4 is arranged on the rotating disk 3; the clamping device 5 is provided with 3 set, set on the main body 1, and evenly arranged along the circumferential direction of the main body 1; the fixed roller 6 is set at the center of the main body 1; the polishing device 7 is set on the fixed roller 6; the second A moving stick 71 can mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com