Clothing production process based on Internet of things and flexible production hanging assembly line

A flexible production, Internet of Things technology, applied in the field of clothing production, can solve problems such as wasted man-hours, unstable transportation, and inability to stop according to actual needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

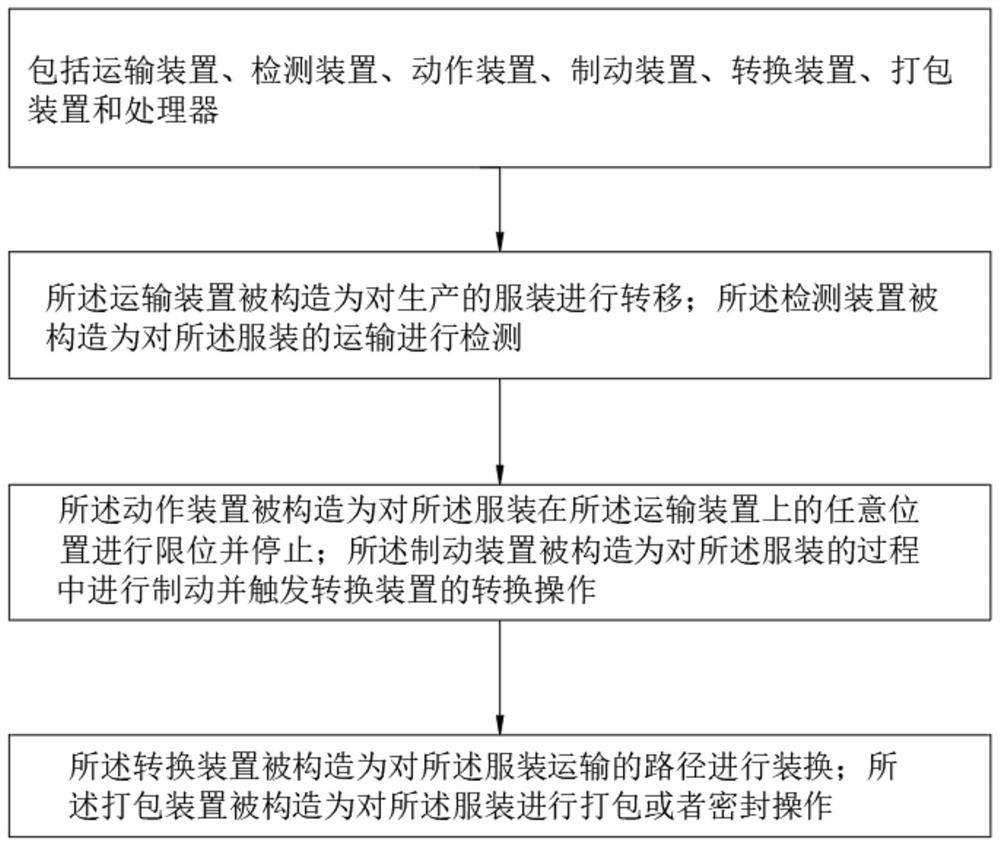

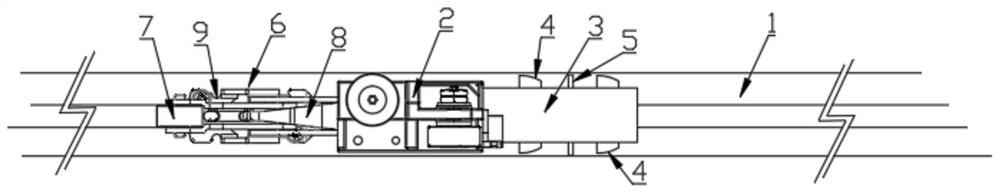

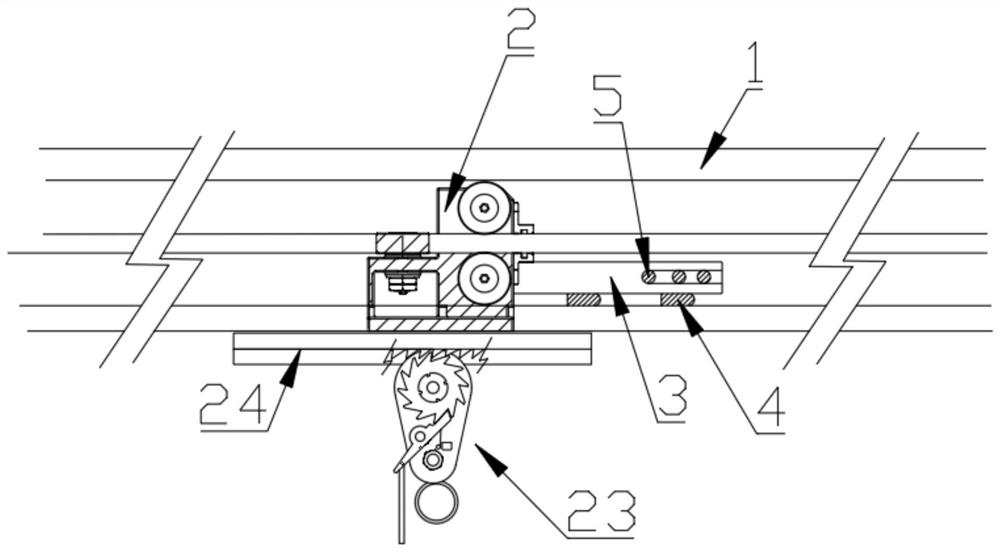

[0036] Embodiment 1: A flexible production and hanging assembly line for clothing production based on the Internet of Things, including a transportation device, a detection device, an action device 3, a braking device, a conversion device, a packaging device and a processor, and the transportation device is configured to The produced clothing is transferred; the detection device is configured to detect the transportation of the clothing; the action device 3 is configured to limit and stop the clothing at any position on the transportation device; The braking device is configured to brake and trigger the conversion operation of the conversion device during the process of the garment; the conversion device is configured to change the path of the garment transportation; the packaging device is configured to Packing or sealing the garment; the transport device includes a transport track 1, several sliding hooks, each sliding mechanism 2, a first driving mechanism and a number of po...

Embodiment 2

[0038] Embodiment 2: This embodiment should be understood to include at least all the features of any one of the foregoing embodiments, and further improve on the basis thereof. Specifically, a flexible production hanging assembly line for clothing production based on the Internet of Things is provided, including: Transport means, detection means, action means 3, braking means, conversion means, packing means and handler, said transport means being configured to transfer the garments produced; said detection means being configured to transport said garments detection; the action device 3 is configured to limit and stop any position of the garment on the transport device; the braking device is configured to brake and trigger the garment during the process The conversion operation of the conversion device; the conversion device is configured to replace the route of the garment transportation; the packaging device is configured to perform the packaging or sealing operation for the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap