A kind of method for producing ortho/p-chlorobenzaldehyde by low-temperature catalytic oxidation

A technology of p-chlorobenzaldehyde and low-temperature catalysis, which is applied in the field of preparation of o-/p-chlorobenzaldehyde, can solve the problems of high reaction temperature, low product selectivity, unfavorable product separation, etc. The effect of low consumption, short process route and green process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

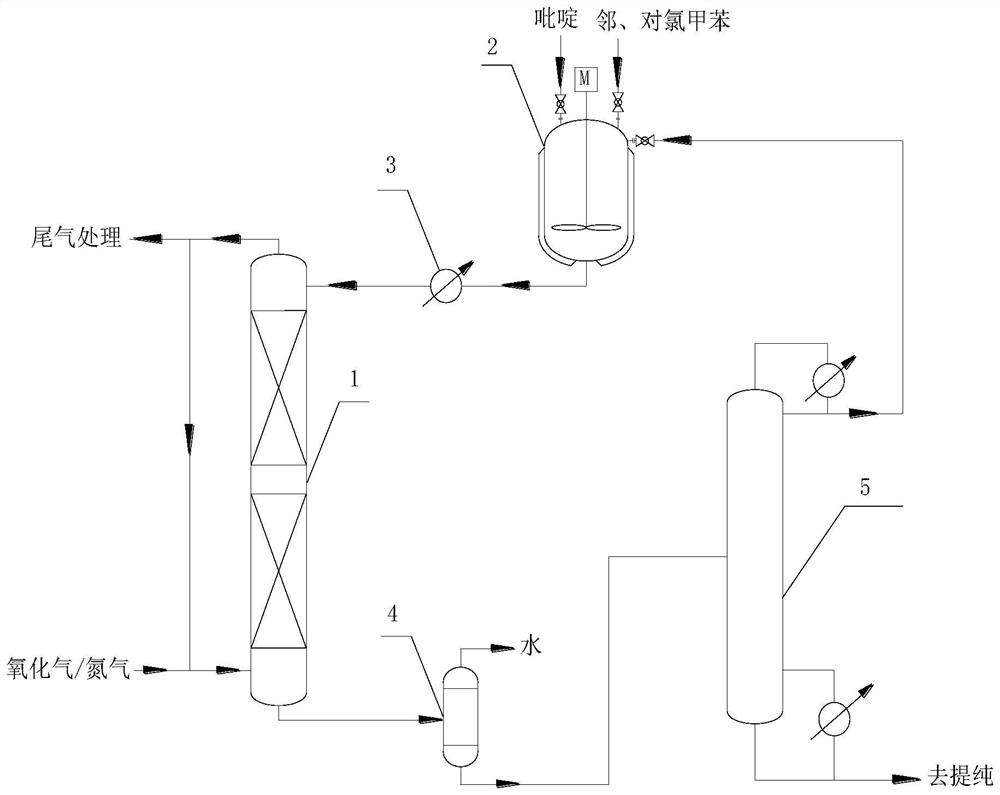

Method used

Image

Examples

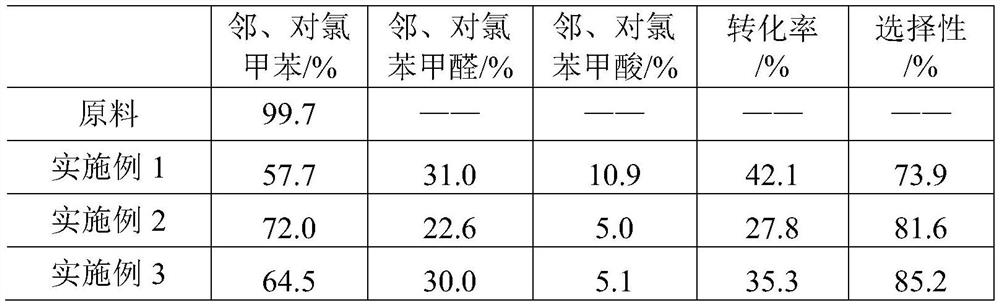

Embodiment 1

[0038] 30.1g Mg 0.1 co 0.5 Ti 0.9 Zr 1.0 o x The composite oxide catalyst is loaded into a quartz reaction tube with a diameter of 20mm, and the reaction tube is installed on the trickle bed reactor, and the space velocity is 500h -1 Nitrogen was introduced, and the temperature was raised to 450°C to activate the catalyst. The activation time was 6 hours. After the catalyst activation was completed, the temperature was lowered to 80.3°C under the protection of nitrogen. Add the mixed solution of pyridine and o- and p-chlorotoluene into the mixing kettle according to the mass ratio of 0.51%, and stir evenly. -1 The mass space velocity is continuously added to the reactor from the upper part of the trickle bed reactor, and at the same time, the nitrogen-oxygen mixed gas oxidant with an oxygen content of 30% is pressed for 710h -1 The volumetric space velocity is continuously fed into the reactor from the bottom of the trickle bed reactor, and the reaction temperature of the...

Embodiment 2

[0041] 30.0g Mg 0.1 co 0.5 Ti 0.9 Zr 1.0 ox The composite oxide catalyst is loaded into a quartz reaction tube with a diameter of 20mm, and the reaction tube is installed on the trickle bed reactor, and the space velocity is 500h -1 Nitrogen was introduced, and the temperature was raised to 450°C to activate the catalyst. The activation time was 6 hours. After the catalyst activation was completed, the temperature was lowered to 119.5°C under the protection of nitrogen. Add the mixed solution of pyridine and o- and p-chlorotoluene into the mixing tank according to the mass ratio of 4.9%, and stir evenly. -1 The mass space velocity is continuously added to the reactor from the upper part of the trickle bed reactor, and the nitrogen-oxygen mixed gas oxidant with an oxygen content of 30% is pressed for 1980h -1 The volumetric space velocity is continuously fed into the reactor from the bottom of the trickle bed reactor, and the reaction temperature of the catalytic oxidation ...

Embodiment 3

[0044] 30.1g Mg 0.1 co 0.5 Ti 0.9 Zr 1.0 o x The composite oxide catalyst is loaded into a quartz reaction tube with a diameter of 20mm, and the reaction tube is installed on the trickle bed reactor, and the space velocity is 500h -1 Nitrogen was introduced, and the temperature was raised to 450°C to activate the catalyst. The activation time was 6 hours. After the catalyst activation was completed, the temperature was lowered to 100.8°C under the protection of nitrogen. Add the mixed solution of pyridine and o- and p-chlorotoluene into the mixing kettle according to the mass ratio of 2.51%, and stir evenly. -1 The mass space velocity is continuously added to the reactor from the upper part of the trickle bed reactor, and at the same time, the nitrogen-oxygen mixed gas oxidant with an oxygen content of 30% is pressed for 1400h -1 The volumetric space velocity is continuously fed into the reactor from the bottom of the trickle bed reactor, and the reaction temperature of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap