Process for supercritical CO2 extraction of agilawood essential oil and optimization method thereof

A kind of agarwood essential oil, supercritical technology, applied in the direction of essential oil/spice, fat production, etc., can solve the problems of environmental and human body damage, loss of agarwood raw materials, lack of harmful low extraction rate agarwood essential oil extraction methods, etc., to achieve high extraction rate , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Air-dry the purchased agarwood in a cool and ventilated place, then chop the agarwood, and then crush it with a crusher to obtain agarwood powder, pass it through a standard sieve as required, and store it in a sealed and dry place for later use.

[0054] Univariate analysis:

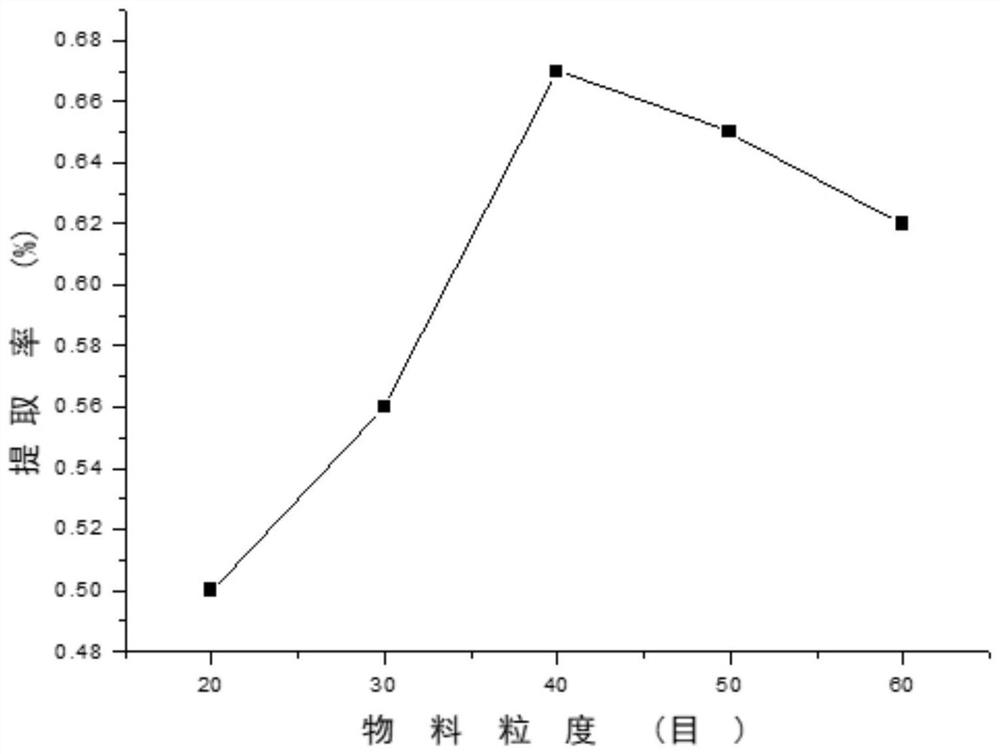

[0055] 1) The effect of the crushed particle size of agarwood on the extraction yield of agarwood essential oil:

[0056] Accurately weigh 100g of agarwood powder and fill it in the extraction kettle. After filling, turn on the instrument, and examine the different particle sizes (60 mesh, 50 mesh, 40 mesh, , 30 mesh, 20 mesh) on the extraction rate of agarwood essential oil.

[0057] like figure 1 As shown, the overall trend of the curve of particle size and extraction rate is that the smaller the particle size, the higher the extraction rate. Because the extract particles are smaller, the CO 2 The larger the contact surface, the more favorable the dissolution of the solute, and the more act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com