A lubricating element used for drag reduction in water-containing heavy oil production and transportation in wellbore

A heavy oil and component technology, applied in the field of heavy crude oil production, transportation and drag reduction, can solve problems such as affecting oil well production, failing to achieve viscosity reduction effect, heating depth limitation, etc., reducing surface water treatment facilities and reducing surface gathering and transportation. Cost, effect of reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

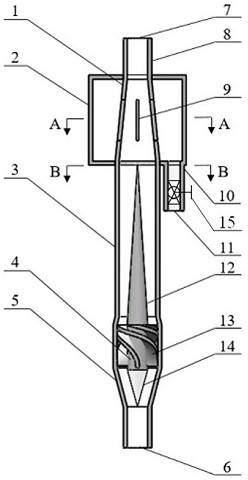

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

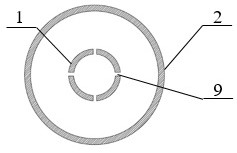

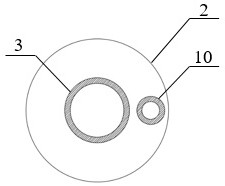

[0018] The invention provides a lubricating element for reducing drag in the production and transportation of water-containing heavy oil in the wellbore, comprising: a middle rod (4), guide vanes (13), a central cone (12) and a steady flow cone (14) The guide part is a casing part made up of a liquid inlet pipe (5), a swirl pipe (3), an outlet pipe (1), a drain chamber (2), a drain pipe (10) and a ring pipe (8). Specifically, the appearance of the liquid inlet pipe (5) is funnel-shaped, the end with a larger diameter is connected to the swirl pipe (3), and the end with a smaller diameter is connected to the upstream collection and transportation pipe; there is a section in the middle of the swirl pipe (3). The diameter of the pipe is tapered, which can not only prevent the guide part from sliding into the outlet pipe (1) during the as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com