Method for testing gas adsorption quantity of water-containing shale

A test method, shale technology, applied in the field of oil and gas exploration, can solve the problems of lack of research on methane adsorption gas measurement methods, damage to the original structure of shale clay minerals, and non-consideration

Active Publication Date: 2020-12-08

INST OF GEOMECHANICS

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The sample preparation steps of this method are cumbersome, and the original structure of shale clay minerals may be destroyed during the high-temperature drying process. More importantly, the result of this method is not the methane adsorption behavior of shale samples under the condition of original formation water, so it is not applicable Methane Isotherm Sorption Test on In Situ Hydrous Shale

In addition, this method does not take into account the dissolved methane gas in water in shale samples under high pressure conditions, which will cause the measured methane adsorption gas to be higher than the actual adsorption gas amount of water-bearing shale

[0004] At present, there is a lack of research on the determination of methane adsorption capacity of in-situ water-bearing shale, so it is necessary to establish a simple and fast method that can accurately and objectively measure the methane adsorption capacity of in-situ water-bearing shale

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

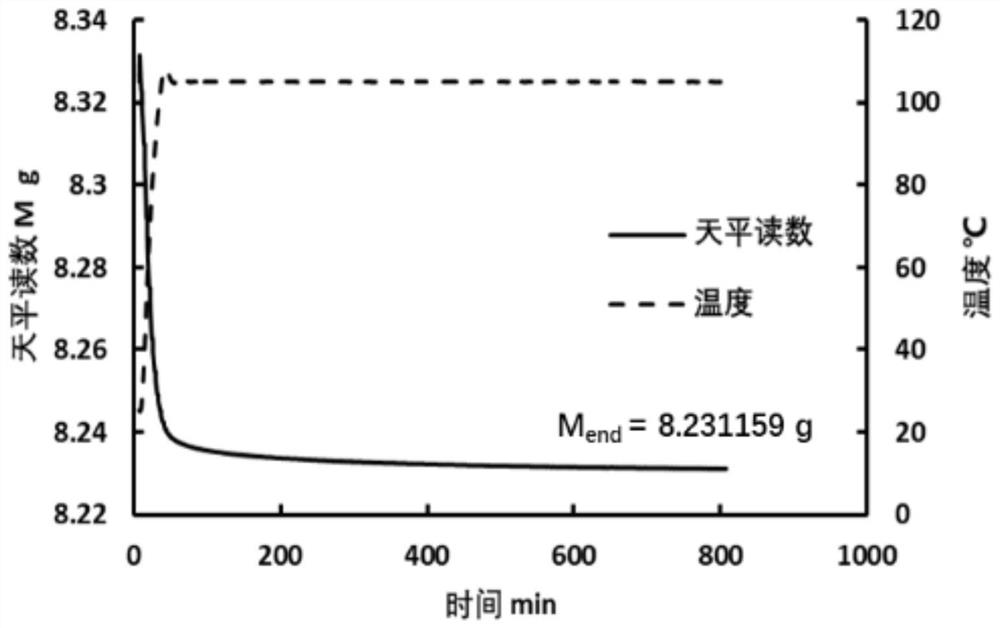

[0049] The shale samples (about 3-5g) were crushed into 20-35 mesh particles in a sealed environment, and kept sealed to avoid water loss as much as possible.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

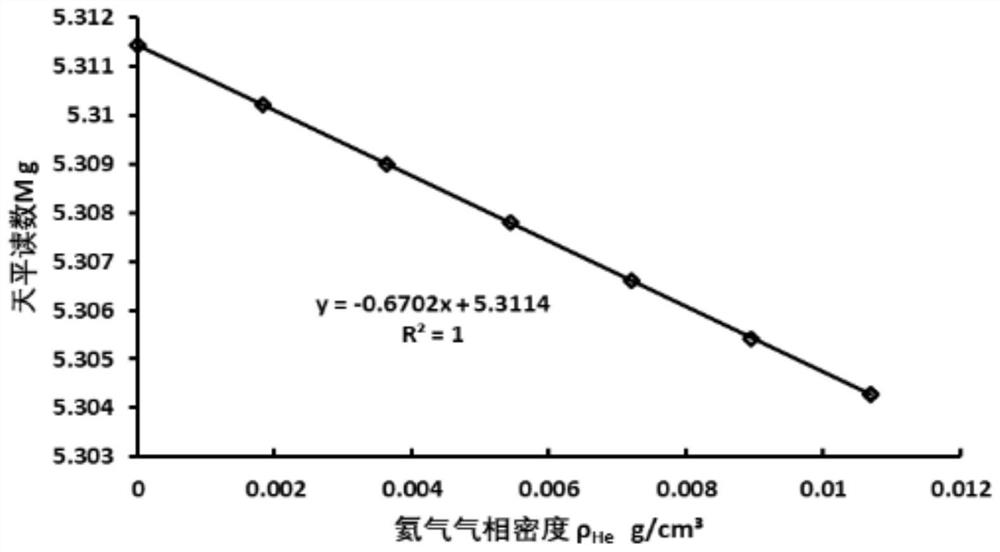

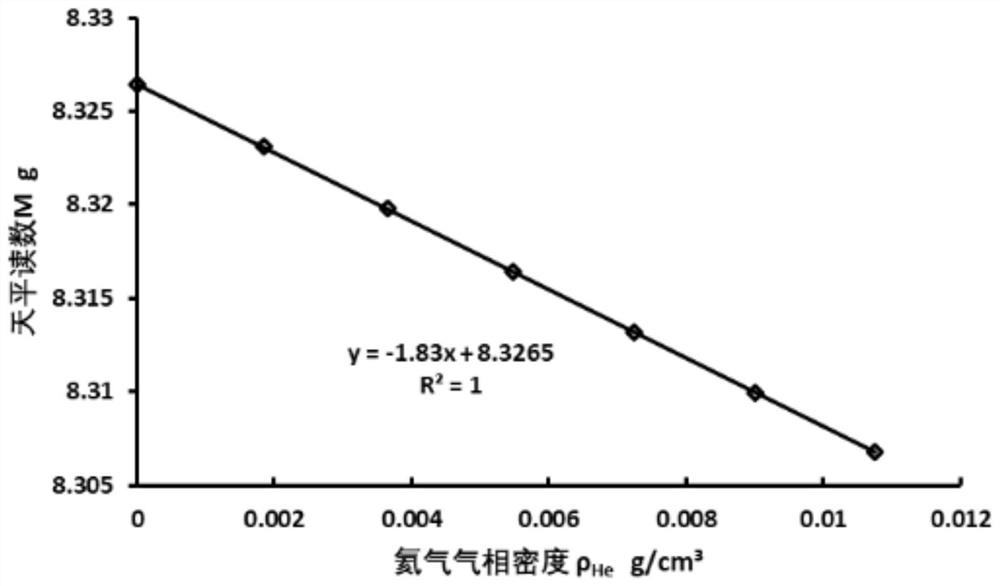

A method for testing a gas adsorption quantity of water-containing shale comprises the following steps: providing an in-situ water-containing shale particle sample; carrying out a blank test to obtainthe mass and the volume of the sample barrel; performing a buoyancy test to obtain the total mass and the total volume of the sample barrel and the sample; obtaining the mass and the volume of the sample based on the total mass and the total volume of the sample barrel and the sample and the mass and the volume of the sample barrel; performing methane isothermal adsorption test on a sample, and obtaining methane gas phase density and sample mass increment under different pressures based on a test result and the total mass and total volume of a sample barrel and the sample; testing the mass loss of the sample based on a thermal weight loss method to obtain the in-situ free water content of the sample; obtaining an original methane isothermal excess adsorption curve based on the methane gasphase density and the sample mass increment under different pressures; and correcting the original methane isothermal excess adsorption curve by incrementally deducting the dissolved gas mass from the sample mass. The method can more accurately and objectively determine the methane adsorption capacity of the in-situ water-containing shale.

Description

technical field [0001] The invention belongs to the technical field of oil and gas exploration, and in particular relates to a method for testing the amount of gas absorbed by water-bearing shale. Background technique [0002] The main component of shale gas is methane, and its occurrence phases in shale reservoirs include adsorbed state, free state and dissolved state. Among them, the content of adsorbed shale gas directly determines the development value and stable production capacity of shale gas reservoirs, so the methane adsorption capacity of shale is the most critical parameter in shale gas resource evaluation and sweet spot prediction. At present, the acquisition of this parameter depends on the test and analysis results of shale reservoir samples in the laboratory. There are two main types of determination methods, one is volumetric method and the other is gravimetric method. The latter uses a high-temperature and high-pressure isothermal adsorption instrument with...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N5/02

CPCG01N5/02

Inventor 俞雨溪王宗秀张凯逊冯兴强李宗星

Owner INST OF GEOMECHANICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com