Material performance testing method and testing tool

A technology of material properties and testing methods, applied in the field of materials, can solve the problems of large amount of superplastic forming/diffusion bonding performance testing, high development costs, and large energy consumption, so as to shorten the performance testing cycle, reduce development costs, and reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

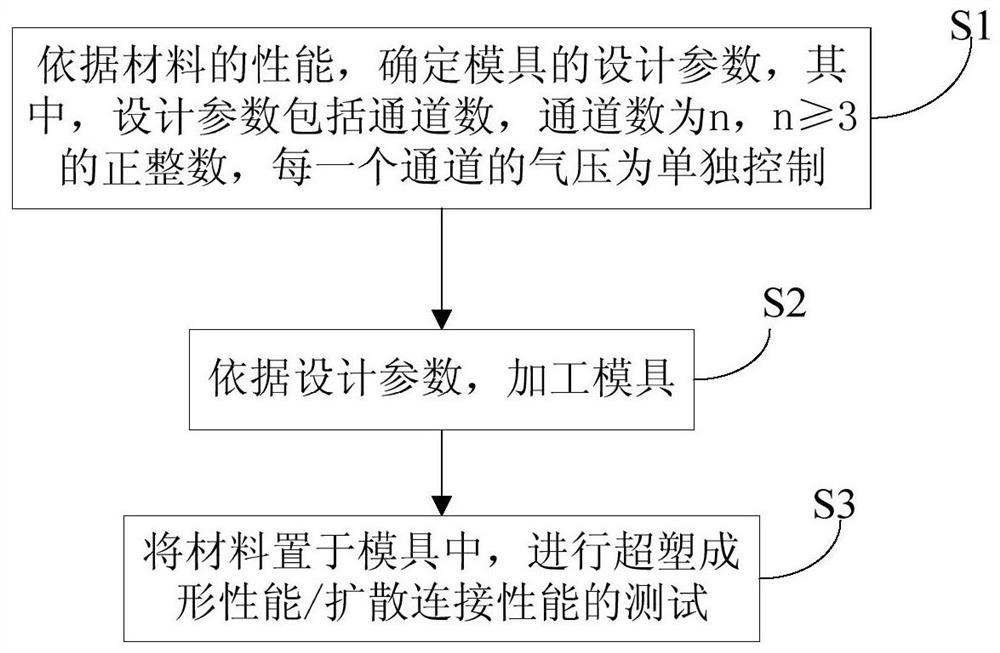

[0086] The specific technical scheme of superplastic forming performance test is as follows:

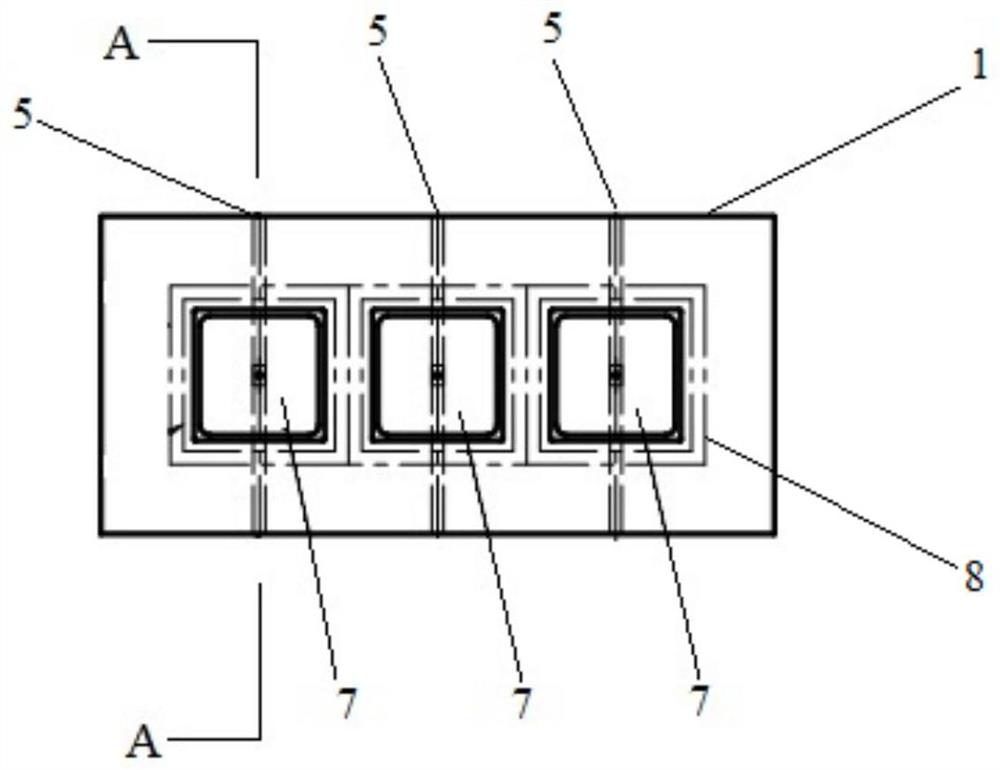

[0087] 1. Mold design

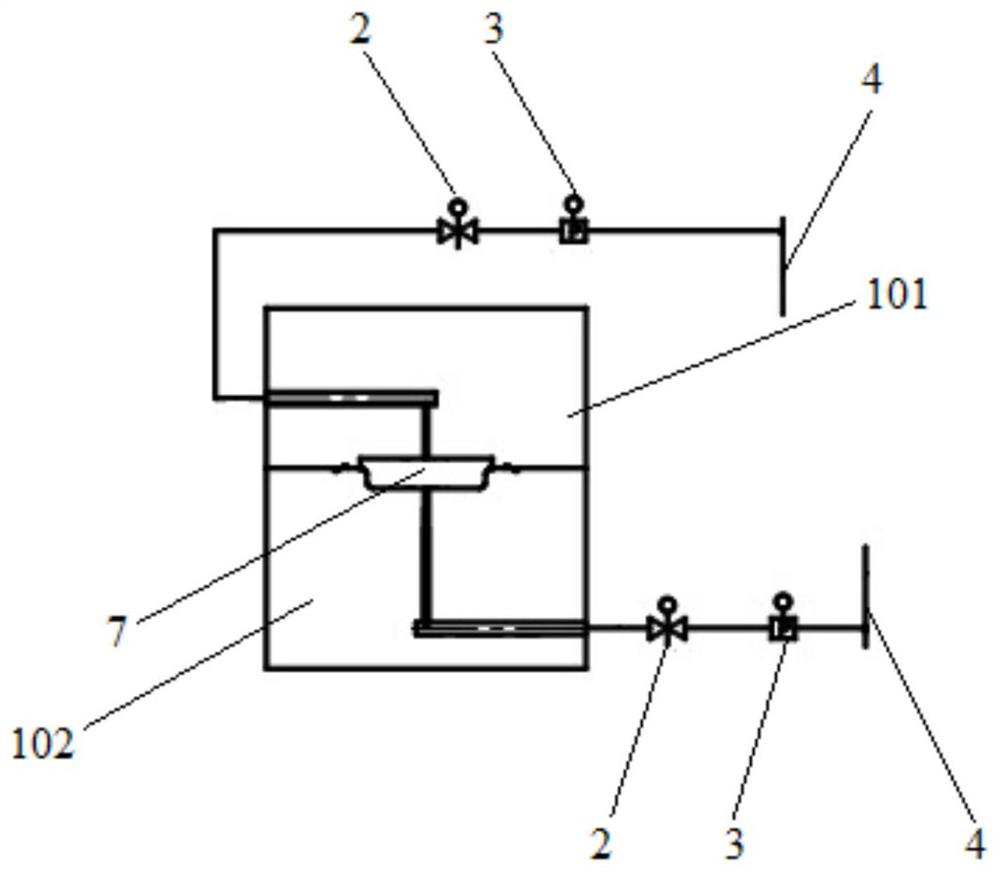

[0088] According to the performance of the test material aluminum alloy, the number of channels in the design mold is 6, each channel of the upper and lower molds is square, and the depths of the lower mold are: 10mm, 20mm, 30mm, 40mm, 50mm and 60mm; A row of sealing stems is designed separately in each channel; a vent hole is designed in each channel of the upper and lower molds, and each vent hole is connected to the air circuit with a pressure reducing valve and a switch valve to realize the air pressure of each channel individual controls, as shown in the figure.

[0089] 2. Mold processing

[0090] According to the mold design drawings, heat-resistant alloy steel Ni 7 N carries out the processing of the mould, and welds the pipelines with pressure reducing valves and switching valves on all the vent holes of the mould.

[0091] 3. Superplastic forming...

Embodiment 2

[0100] The specific technical scheme of diffusion connection performance test is as follows:

[0101] 1. Mold design and processing

[0102] Mold is identical with the mold of embodiment one.

[0103] 2. Diffusion connection test

[0104] According to the diffusion bonding process flow, the diffusion bonding performance test of different process parameters is carried out. The process is as follows:

[0105] 1) Cut the titanium alloy plate according to the size of the mold channel, and pickle; at the same time, seal and weld the plates in pairs, and conduct a vacuum test to ensure that the internal pressure of the blank after sealing and welding is less than 0.01MPa;

[0106] 2) Put the mold into the furnace, clean the surface and check the air tightness, and insert the thermocouple into the mold at the same time; connect the pipelines of each channel of the upper and lower molds with the intake and exhaust pipelines, and open the switch valve, Use the pressure reducing valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com