Safe and efficient hot-dip galvanized iron wire cooling and passivating device

A technology of hot-dip galvanizing and iron wire, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of shortening the service life of hot-dip galvanizing iron wire and affecting the timely progress of the process, so as to improve the cooling effect and ensure Processing quality, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

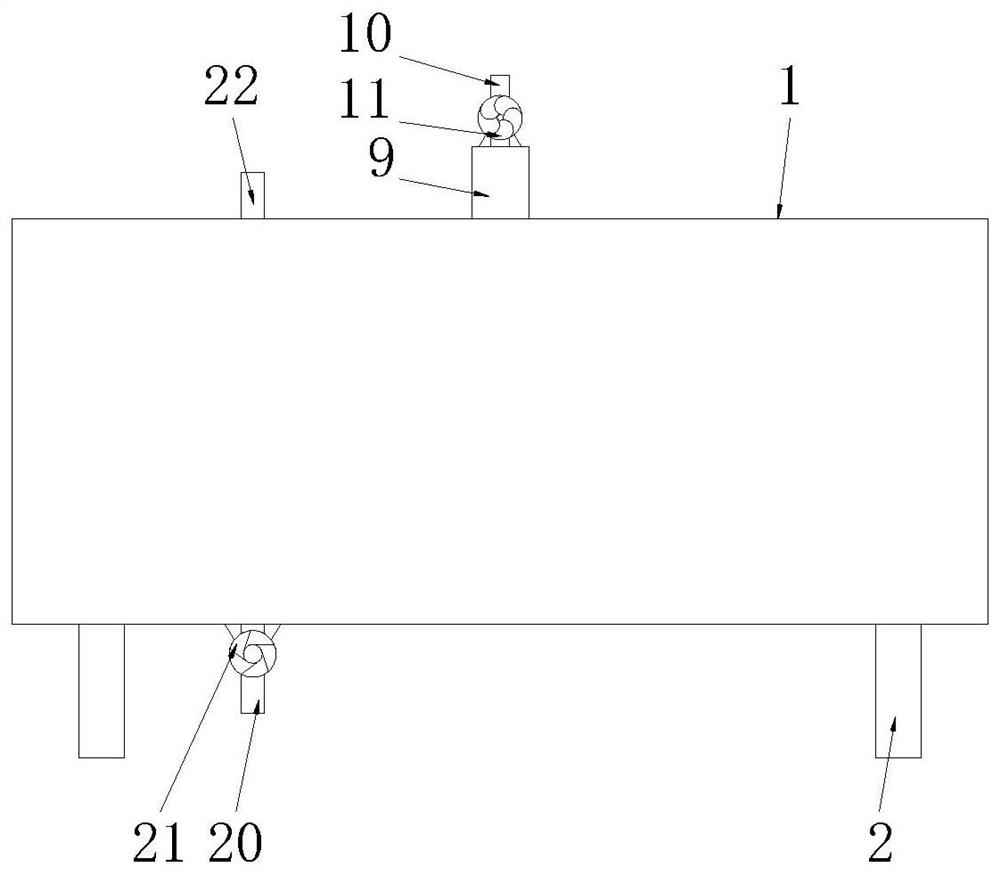

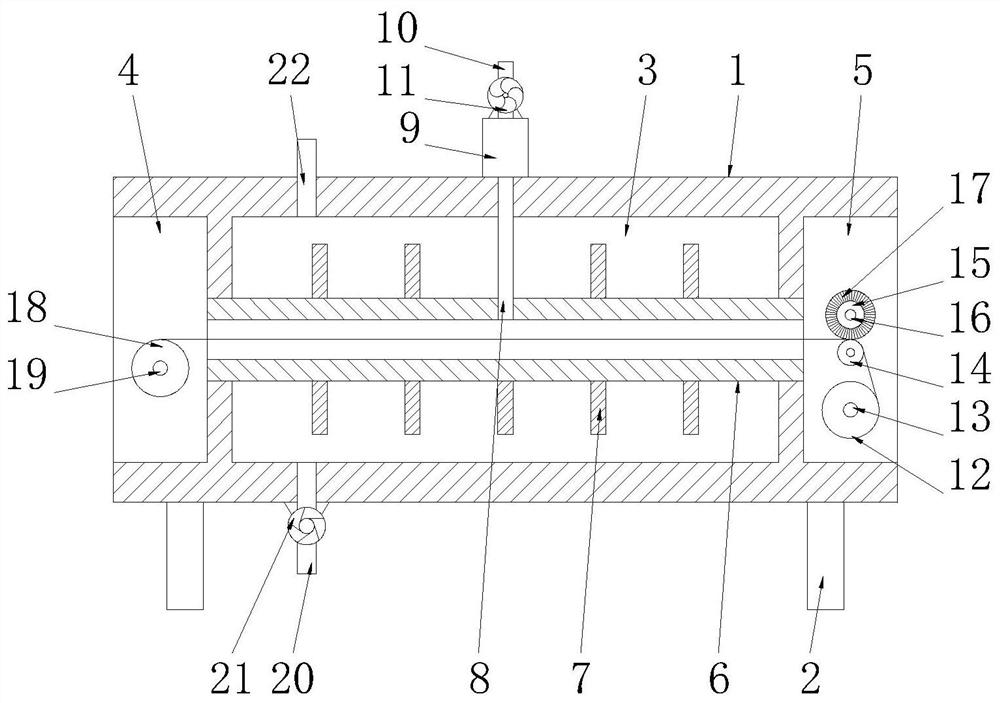

[0020] See Figure 1-3 , a safe and high-efficiency hot-dip galvanized iron wire cooling passivation device, including a body 1, a plurality of legs 2 are uniformly arranged at the bottom of the body 1, a heat dissipation cavity 3 is arranged inside the body 1, and a feeding material is arranged at one end of the body 1 cavity 5, the other end of the body 1 is provided with a discharge cavity 4, the heat dissipation cavity 3 is provided with a hot-dip galvanized iron wire channel 6, the hot-dip galvanized iron wire channel 6 is made of heat-conducting materials, and the hot-dip galvanized iron wire channel 6 The two ends are respectively connected to the discharge chamber 4 and the feed chamber 5, and the top end of the hot-dip galvanized wire passage 6 is connected to the connecting pipe 8, and the other end of the connecting pipe 8 runs through the top wall of the cooling chamber 3 and connects to the purification box 9. The air intake end of the purification box 9 is connec...

Embodiment 2

[0024] The difference from Embodiment 1 is that: the bottom side of the heat dissipation chamber 3 is connected to the water inlet pipe 20, and the water supply pump 21 is installed on the water inlet pipe 20, and the top side of the heat dissipation chamber 3 is connected to the water outlet pipe. 22. Inject cold water into the heat dissipation cavity 3 through the water supply pump 21 and the water inlet pipe 20, and then use the cold water to cooperate with the hot-dip galvanized iron wire channel 6 to cool the hot-dip galvanized iron wire, and the water after heat exchange is discharged through the water outlet pipe 22. Cooling with cold water can greatly improve the cooling effect of the entire device, thereby ensuring the production quality of hot-dip galvanized iron wire.

[0025] The working principle of Embodiment 1-2: when in use, first inject cold water into the heat dissipation cavity 3, so that the cold water passes through the hot-dip galvanized iron wire channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com