Hot cutting device for chemical fabric production and using method thereof

A chemical fiber cloth, eager technology, used in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of high energy consumption, increased labor, low production efficiency, etc., achieve small energy loss, reduce labor intensity, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

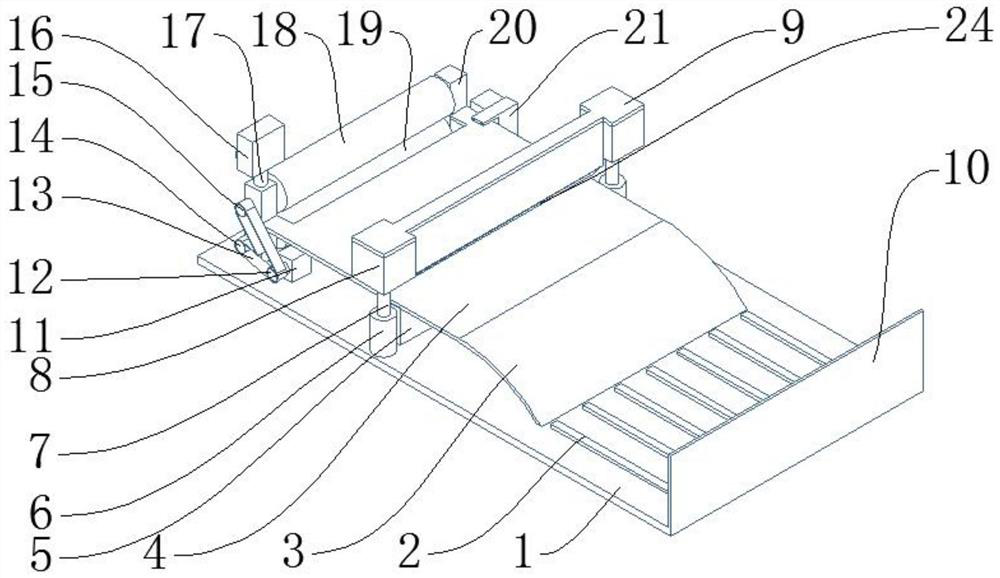

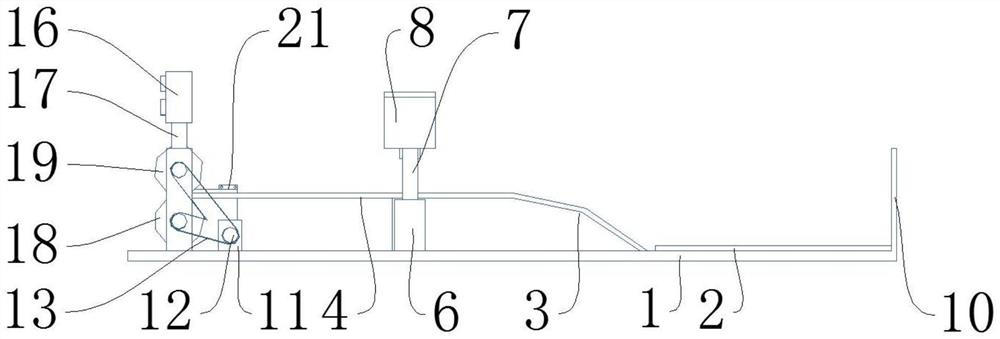

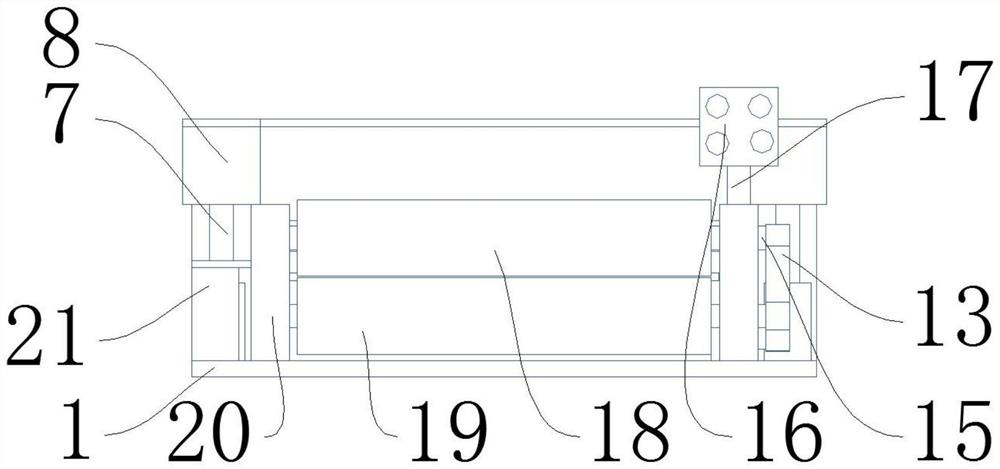

[0039] like Figure 1-Figure 6 As shown, the hot-cutting device for chemical fiber cloth production includes a bottom plate 1 and a cutting module 8. The function of the bottom plate 1 is to carry parts and the function of the cutting module 8 is to cut the chemical fiber cloth. The upper part of the bottom plate 1 is provided with a baffle plate 10 to block the cutting For the finished chemical fiber cloth, one side of the baffle 10 is provided with an anti-skid mark 2 to prevent the cut chemical fiber cloth from slipping off, one side of the anti-skid mark 2 is provided with a slideway 3 to transport the chemical fiber cloth, and one side of the slideway 3 is provided with a transmission plate 4, To transmit the chemical fiber cloth, a displacement sensor 21 is arranged at the rear of the transmission plate 4 to detect the length of the chemical fiber cloth. The lower part of the transmission plate 4 is provided with an outrigger 5 to carry the transmission plate 4, and a hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com