Steel cord with compact structure and preparation method thereof

A steel cord and compact technology, which is applied in the field of steel cord with compact structure and its preparation, can solve the problems of affecting the quality of tire finished products, poor rubber penetration performance, high air content, etc., so as to improve structural stability and The effect of anchoring, improving adhesion, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

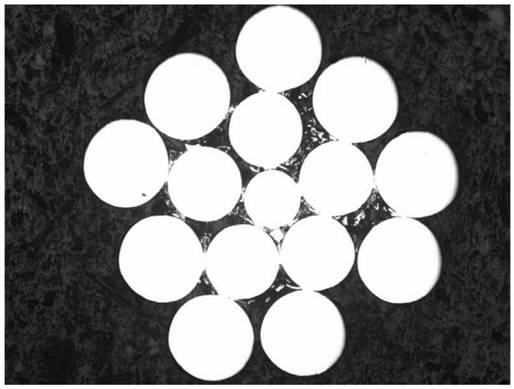

[0025] The steel cord with a compact structure in this embodiment includes a core wire with a diameter of 0.14 mm. Around the core wire, there are multiple layers of wires with the same twist direction and the same lay length as the core wire. The layer wires include the middle Layer wire and outer layer wire, the middle layer wire is composed of five middle layer monofilaments with a diameter of 0.173mm, and the outer layer wire is composed of nine outer layer monofilaments with a diameter of 0.194mm.

[0026] The preparation method of the steel cord of the present embodiment comprises the following steps:

[0027] (1) Roughly draw a wire rod with a diameter of 5.5 mm after surface treatment, and then normalize to remove work hardening after being drawn to a diameter of 2.2 mm, and then carry out intermediate drawing to obtain a dry-drawn steel wire with a diameter of 1.0 mm; (2) The dry-drawn steel wire is subjected to lead bath isothermal quenching in turn, and then electro...

Embodiment 2

[0029] The steel cord with a compact structure in this embodiment includes a core wire with a diameter of 0.17 mm, twisted around the core wire with multiple layers of wires with the same twist direction and the same lay length as the core wire, and the layer wires include the middle Layer wire and outer layer wire, the middle layer wire is composed of five middle layer monofilaments with a diameter of 0.248mm, and the outer layer wire is composed of nine outer layer monofilaments with a diameter of 0.28mm.

[0030] The preparation method of the steel cord of the present embodiment comprises the following steps:

[0031] (1) Roughly draw a wire rod with a diameter of 5.5mm after surface treatment, pull it to a diameter of 3.2mm, remove the work hardening after normalizing, and then carry out intermediate drawing to obtain a dry-drawn steel wire with a diameter of 1.8mm; (2) The dry-drawn steel wire is subjected to lead bath isothermal quenching in sequence, and then electropla...

Embodiment 3

[0033] The steel cord with a compact structure in this embodiment includes a core wire with a diameter of 0.16mm, twisted around the core wire with multiple layers of wires with the same twist direction and the same lay length as the core wire, and the layer wires include the middle Layer wire and outer layer wire, the middle layer wire is composed of five middle layer monofilaments with a diameter of 0.205mm, and the outer layer wire is composed of nine outer layer monofilaments with a diameter of 0.235mm.

[0034] The preparation method of the steel cord of the present embodiment comprises the following steps:

[0035] (1) Roughly draw a wire rod with a diameter of 5.5mm after surface treatment, and then normalize to remove work hardening after being drawn to a diameter of 2.7mm, and then carry out intermediate drawing to obtain a dry-drawn steel wire with a diameter of 1.4mm; (2) The dry-drawn steel wire is subjected to lead bath isothermal quenching in sequence, and then e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com