System for efficiently utilizing afterheat and circulating multiple refrigerants

A circulation system and refrigerant technology, applied in solar heating systems, refrigerators, refrigeration components, etc., can solve problems that do not conform to human development trends, use and development of new energy are urgent, and achieve energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

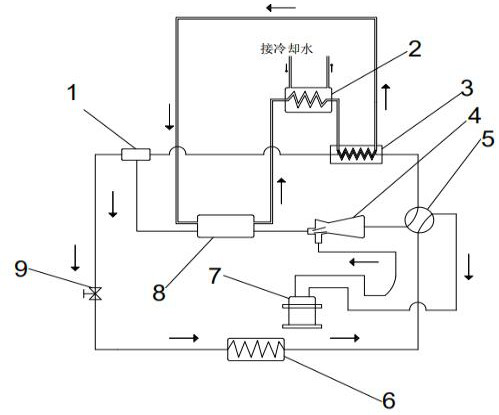

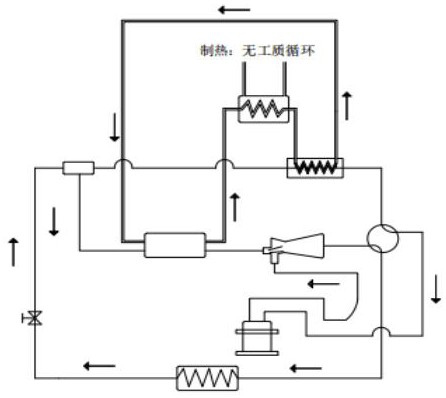

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] Such as figure 1 As shown, the high-efficiency utilization of waste heat and multi-refrigerant circulation system includes a gas-liquid separator 1, a heat exchanger 2, a condenser 3, a solar ejector 4, a four-way reversing valve 5, an evaporator 6, a compression Machine 7, generator 8 and throttle valve 9.

[0020] The refrigerant pipeline of the compressor 7 is provided with a mixed refrigerant, and the mixed refrigerant includes two types, one is refrigerant one, which uses R404a, and the other is refrigerant two, which uses R134a;

[0021] When the system is in refrigeration mode, the mixed refrigerant 1 and refrigerant 2 become a high-temperature and high-pressure mixed gas after the compressor 7 does work. After the solar ejector 4 is switched by the four-way reversing valve, the mixed working medium enters the condenser 3, After the heat exchange by the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com